Sand separating and washing all-in-one machine

An all-in-one, sand washing technology, applied in solid separation, wet separation, screening and other directions, can solve the problems of waste of resources, waste of sand and gravel resources, and the need for sedimentation tanks, so as to reduce cleaning costs, reduce stacking time, reduce The effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

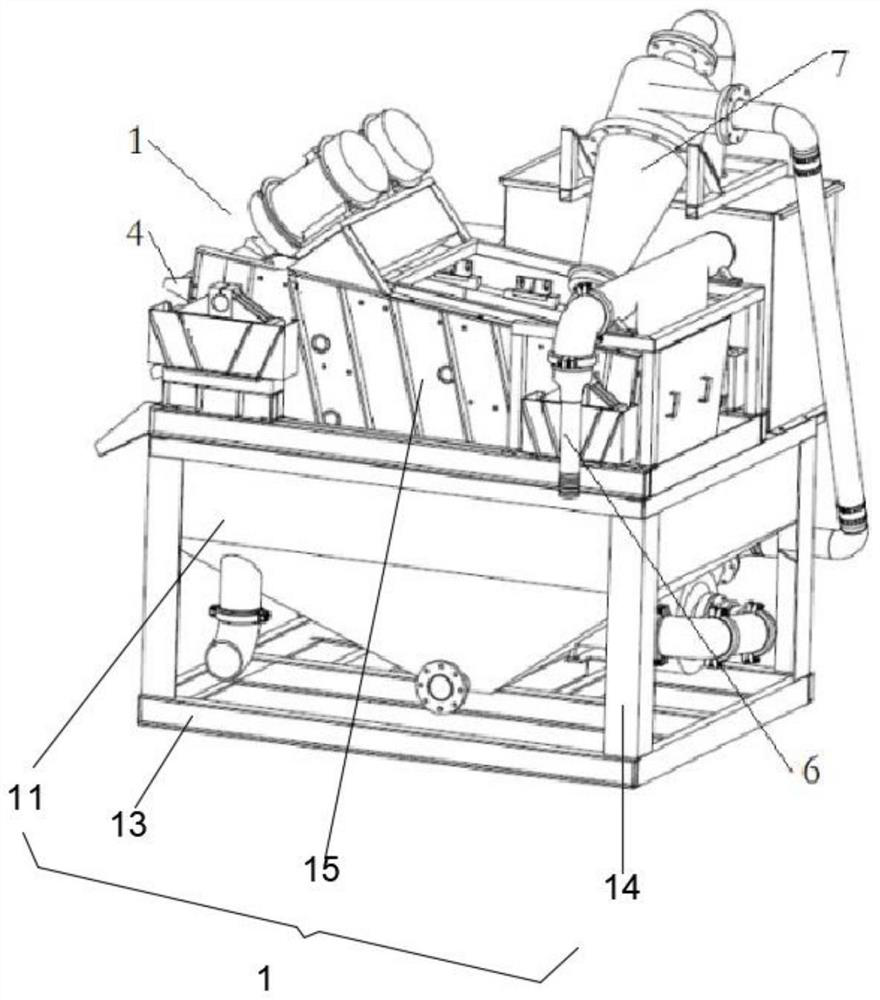

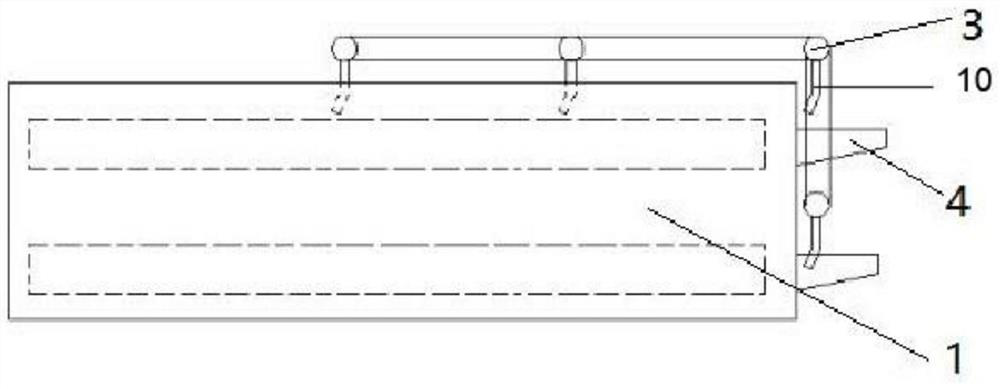

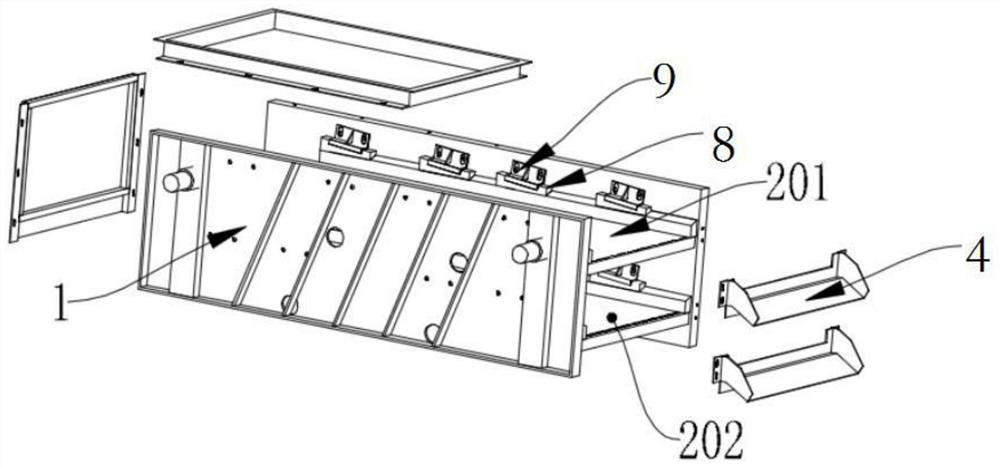

[0024] The first embodiment of the present invention provides an integrated sand washing machine, such as figure 1 As shown, the vibration assembly 1 is included, wherein the vibration assembly 1 includes a slurry storage tank 11, a base 13, a support structure 14, and a vibrating screen box 15.

[0025] The slurry storage tank 11 and the vibrating screen box 15 are connected by a first connecting piece, the slurry storage tank 11 is located below the vibrating screen box 15, above the base 13, the first connecting piece It is screws or bolts, which are connected by screws or bolts, which can facilitate disassembly and assembly, and can improve assembly efficiency. In order to improve the structural strength of the equipment, the slurry storage tank 11 and the vibrating screen box 15 can be welded. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com