Electrode and molten salt electrolysis device

A molten salt electrolysis device and electrode technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problem of low purity of solid electrolysis products, and achieve the effect of reducing potential safety hazards in electricity use, reducing potential safety hazards, and saving wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The inventor analyzed the problems existing in the electrodes in the existing molten salt electrolysis and found that:

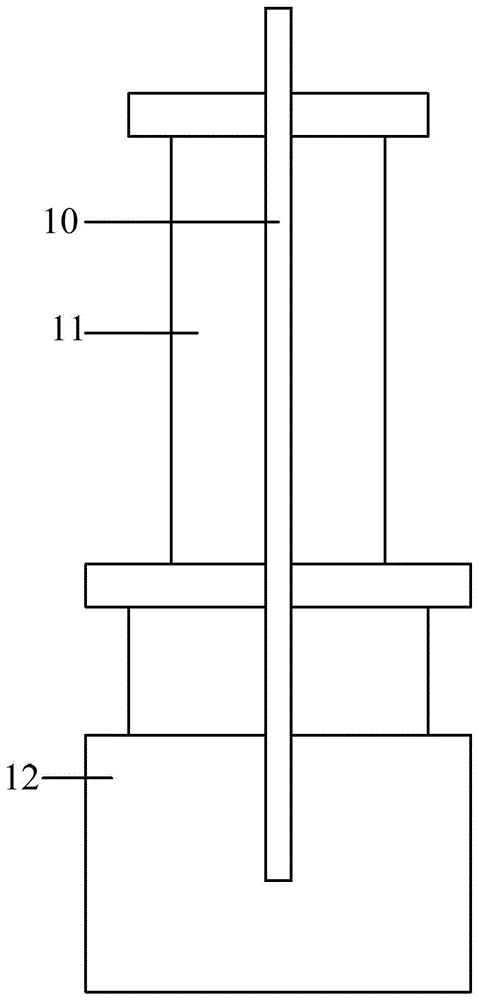

[0029] refer to figure 1 , during the electrolysis process, one end of the electrode 10 is located in the molten electrolytic medium of the electrolytic cell 12 . After the electrolysis reaction was completed, the electrode 10 attached to the solid electrolysis product was lifted, so that most of the electrode 10 in the upper chamber 11 passed through the top of the upper chamber 11 and entered into the air; Insert it into the electrolyzer and proceed to the next electrolysis process. Repeating this many times, most of the electrode 10 in the upper cavity 11 will often be in contact with the air, and will inevitably be corroded by oxygen and water vapor in the air and rust. Rust causes the surface finish of the electrode 10 to decrease and become rough, and regular surface maintenance will also reduce the diameter of the electrode, so when the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com