Carbon fiber inhaul cable capable of being used for large building structure

A technology of building structure and carbon fiber, applied in building components, building structure, construction and other directions, can solve the problems of material mechanical loss, complex sheet specifications, difficult construction, etc., to achieve equal tensile capacity, ensure project quality, and ensure use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] The comparison of embodiment one and embodiment two is shown in the table below:

[0085]

[0086] 3. Experimental analysis and comparison

[0087] In the two embodiments, the nominal cross-sectional area of the rectangular cross-section cable body is 200mm 2 , the nominal cross-sectional area of the circular cross-section cable body is 314mm 2 , in the case of using carbon fiber sheets with the same strength, the rectangular cross-section cable body obtained about 6 times the measured breaking force with a smaller volume.

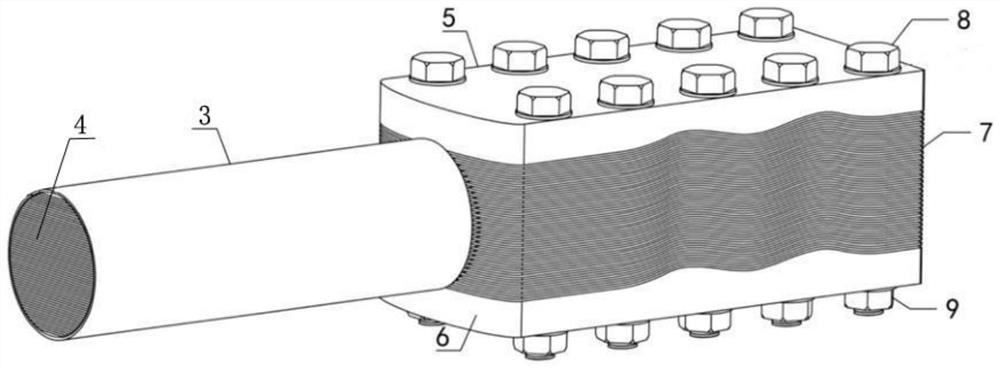

[0088]By comparison, the CFRP cable body with a rectangular cross-section has obvious advantages in the application process compared with the CFRP cable body with a circular cross-section, which are mainly manifested in the following points:

[0089] A. The effective cross-sectional area of the cable body itself = 100%, and the effective use area is more than 1 times that of the circular cross-section cable body.

[0090] B. The specific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile load | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com