Cassava whole powder processing technology

A cassava powder, processing technology, applied in food drying, food science, etc., can solve the problems of residual dandruff, affecting the color and quality of cassava powder, and poor peeling effect of cassava, so as to improve cleanliness and guarantee Quality, pure color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with embodiment.

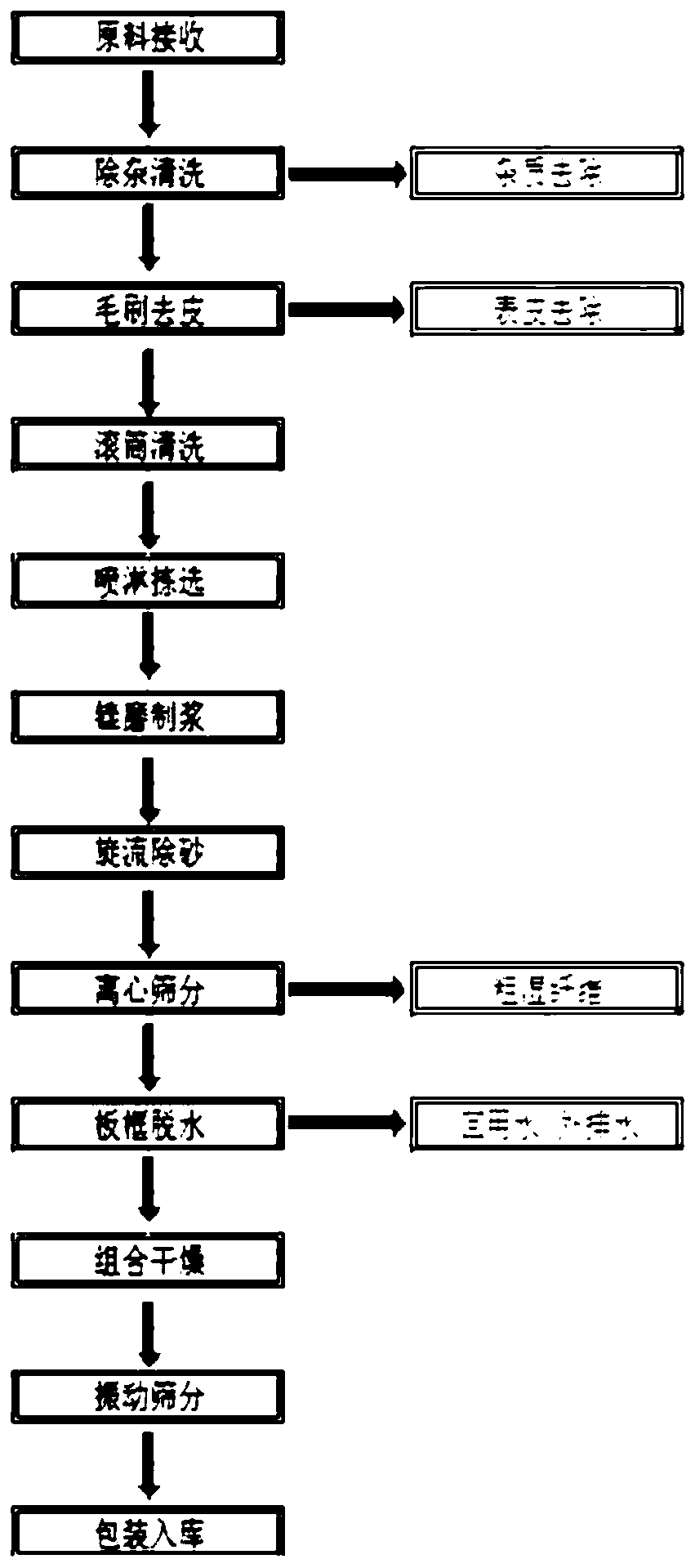

[0019] Such as figure 1 Shown a kind of cassava whole powder processing technology, comprises the steps:

[0020] receive cleaning

[0021] The fresh cassava purchased by the factory is stored in the raw material yard, and is shoveled by a forklift to the receiving hopper on the conveyor, and the raw material is lifted by the inclined conveyor belt and transported to the impurity removal cleaning machine;

[0022] The raw materials lifted by the conveyor directly enter the impurity removal cleaning machine, which has the functions of impurity removal, stone removal, cleaning and dehydration. After fresh cassava passes through the impurity removal cleaning machine, it can remove impurities, stones, mud Sand and other impurity cleaning effect.

[0023] The sand, stones and slag pass through the set sump, and they are manually cleaned regularly.

[0024] friction peeling

[0025] U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com