Multi-station workbench for safety helmet assembly

A multi-station, hard hat technology, applied in the direction of assembly machines, metal processing, manufacturing tools, etc., can solve the problems of cumbersome adjustment process, low production efficiency, affecting production efficiency, etc., and achieve the effect of reducing production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

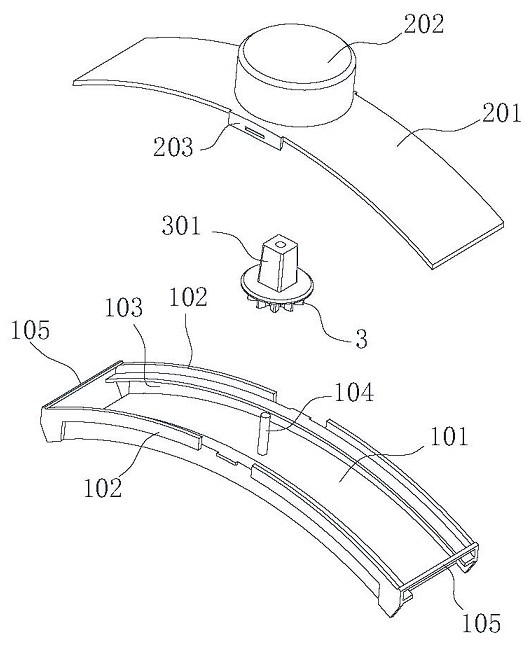

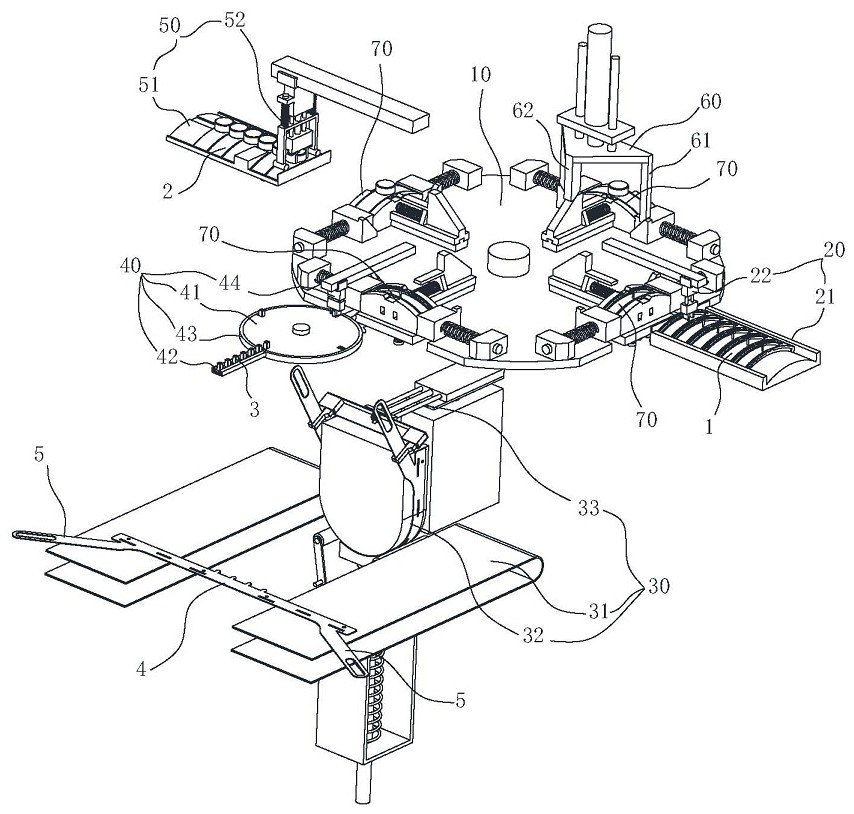

[0034] Such as image 3 As shown, a smart helmet assembly system includes a transfer mechanism 10, the transfer mechanism 10 is provided with a positioning mechanism 70, and the positioning mechanism 70 is used to fix the tightener of the helmet; as figure 2 As shown, the tightener includes an inner half-shell 1 and an outer half-shell 2, the inner half-shell 1 includes an arc-shaped bottom wall 101 and the two arc-shaped sides of the arc-shaped bottom wall 101 protrude toward the outer arc surface. The two side walls 102 are arranged, and the inner sides of the two side walls 102 are provided with arc-shaped grooves 103, and the center of the outer arc surface of the arc-shaped bottom wall 101 is provided with a fixed shaft 104, and the two ends of the two side walls 102 are provided with connecting two sides. 102 of the cross bar 105, the outside of the center of the two side walls 102 is provided with buckles; the outer half shell 2 includes an arc plate 201 that engages w...

Embodiment 2

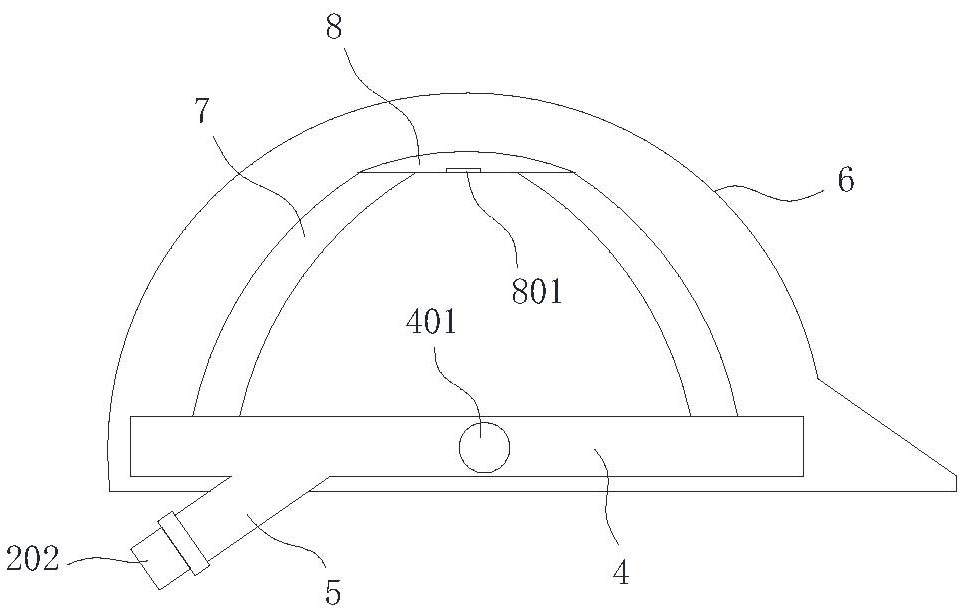

[0048] Such as figure 1 As shown, a smart safety helmet includes a cap shell 6, a top wear 7, a side band 4, a buffer pad 8 and a chin strap, the side band 4 is installed on the inner edge of the cap shell 6, and the top wear 7 is connected with the side band 4 , the buffer pad 8 is located at the center of the top wear 7, and the two ends of the chin strap are connected to the side hoop 4, and the rear side of the side hoop 4 is provided with a drawstring 5 and a tightener for adjusting the tightness of the side hoop 4; the top wear 7 A first pressure sensor 801 is provided on the top, and a second pressure sensor 401 is provided on the side hoop 4. The tightener is driven by a servo motor, and the first pressure sensor 801, the second pressure sensor 401 and the servo motor are all connected with the control module electric connected, when the first pressure sensor 801 detects head pressure, the control module controls the servo motor to tighten the drawstring 5, and when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com