Dust removal type ceramic grinding equipment

A technology of ceramics and equipment, which is applied in the field of dust-removing ceramic grinding equipment, can solve the problems of staff health threats, dust flying, etc., and achieve the effect of avoiding dust diffusion and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

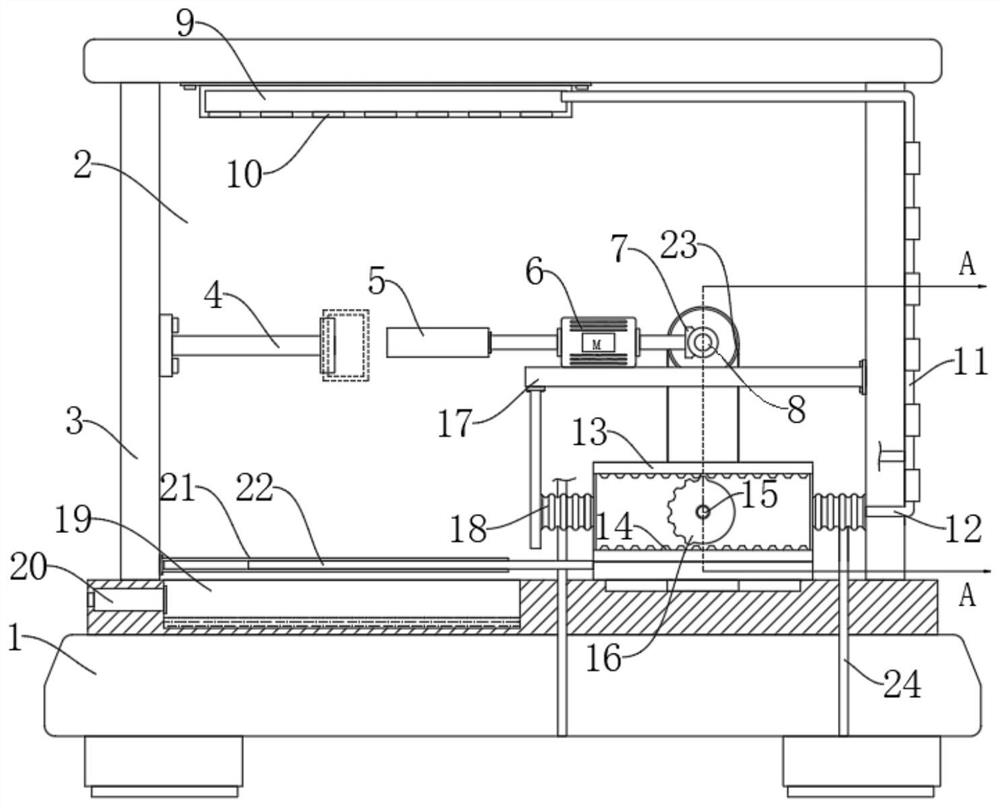

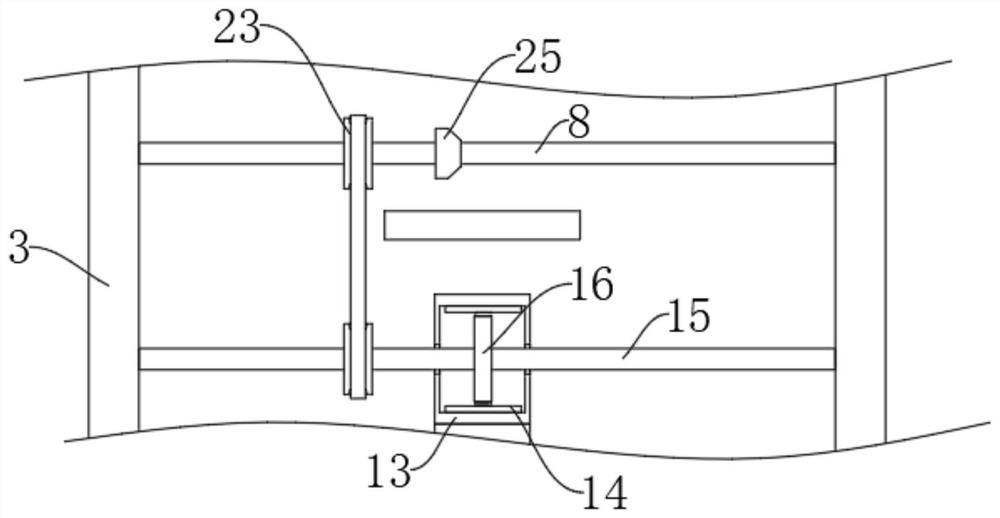

[0029] refer to Figure 1-4 , comprising a base 1, the upper end of the base 1 is fixedly connected with a grinding box 3, the grinding box 3 is provided with a processing chamber 2, and the right inner wall of the processing chamber 2 is fixedly connected with a horizontal plate 17, which can be installed on the front side of the grinding box 3 A sliding door for picking and placing ceramics that need to be polished;

[0030] A grinding mechanism is installed on the upper end of the horizontal plate 17, and the grinding mechanism is used for grinding ceramics;

[0031] The area below the horizontal plate 17 in the processing chamber 2 is provided with a blower mechanism, which is used to blow the dust generated by grinding;

[0032] The inner bottom of the processing chamber 2 is provided with an ash collection tank 19, and a dust collection mechanism matched with a blower mechanism is installed at the notch of the ash collection tank 19.

[0033] Wherein, the grinding mech...

Embodiment 2

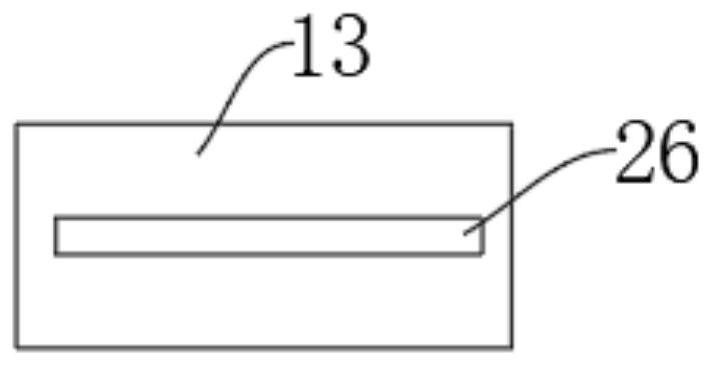

[0046] refer to Figure 5 The difference between this embodiment and Embodiment 1 is that the ends of the two air inlet pipes 24 away from the corresponding airbags 18 both extend into the air outlet 20 .

[0047] In this embodiment, its functional principle can be explained through the following operation mode: when the gear box 13 moves left and right, it will absorb gas from the outside through the air inlet pipe 24, and when the end of the air inlet pipe 24 away from the corresponding air bag 18 extends to the air outlet 20 , so that the air outlet 20 produces a suction force, which forms a circulating airflow with the gas discharged from the air outlet 10, and the dust generated by grinding will move with the circulating airflow, which can further limit the movement direction of the dust (in order to observe the grinding direction during grinding) situation, the sliding door on the front side is open, if there is no circulating air flow, the situation of part dust flying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com