An automatic cutting and stacking machine and its working method

A stacking machine and cutting technology, which is applied in metal processing and other directions, can solve the problems of heavy metal cardboard, easy slipping of cardboard, and high labor intensity, and achieve the effects of easy cutting, increased overall height, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0031] Example.

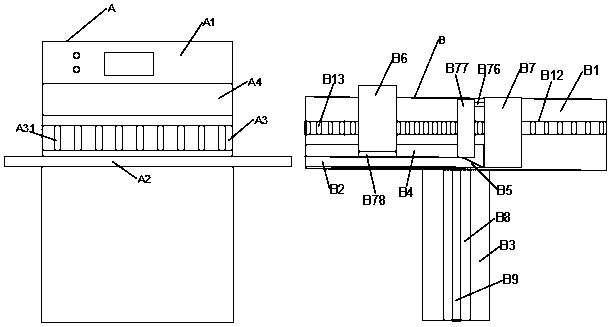

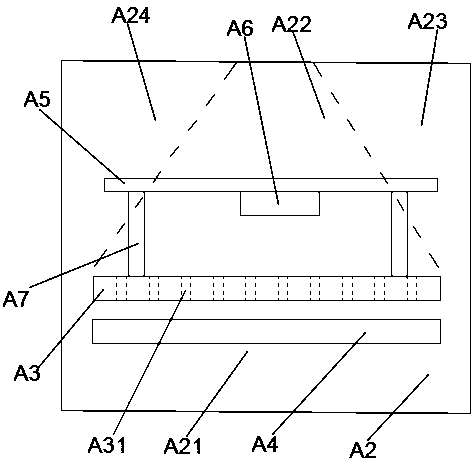

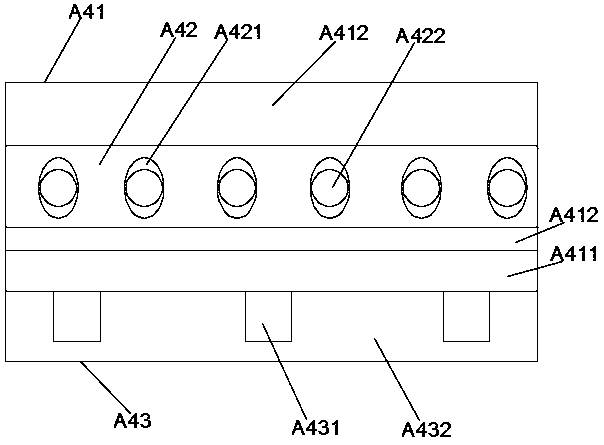

[0032] see Figure 1 to Figure 6 , an automatic cutting and stacking machine, including a cutting mechanism A and a stacking mechanism B, the cutting mechanism A and the stacking mechanism B are adjacently arranged; the cutting mechanism A includes a machine body A1, a supporting mechanism A2, and a pushing mechanism A3 , cutting mechanism A4, supporting frame A5, air induction equipment A6 and pushing arm A7; supporting mechanism A2 is located in the middle of machine body A1, pushing mechanism A3 and cutting mechanism A4 are located above supporting mechanism A2, pushing mechanism A3 and cutting mechanism A4 Adjacent; the cutting mechanism A4 includes a knife body A41, a reinforcing mechanism A42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com