Charging barrel of multifunctional hot melting adhesive powder mixing and stirring machine

A hot-melt adhesive powder and mixer technology, applied in mixers, mixer accessories, dissolution, etc., can solve problems such as damage, achieve good sealing effect, reduce waste of raw materials, avoid production impact and equipment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

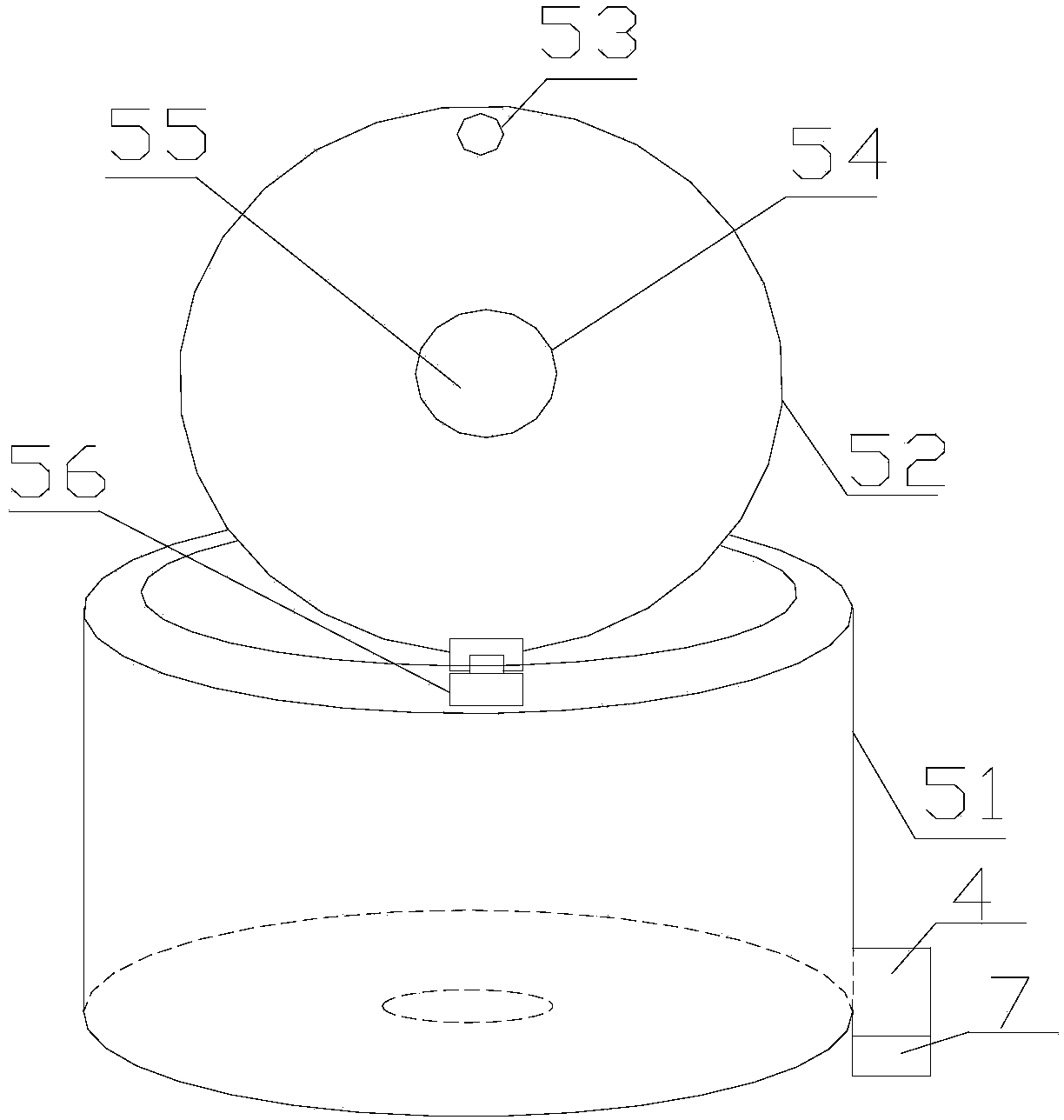

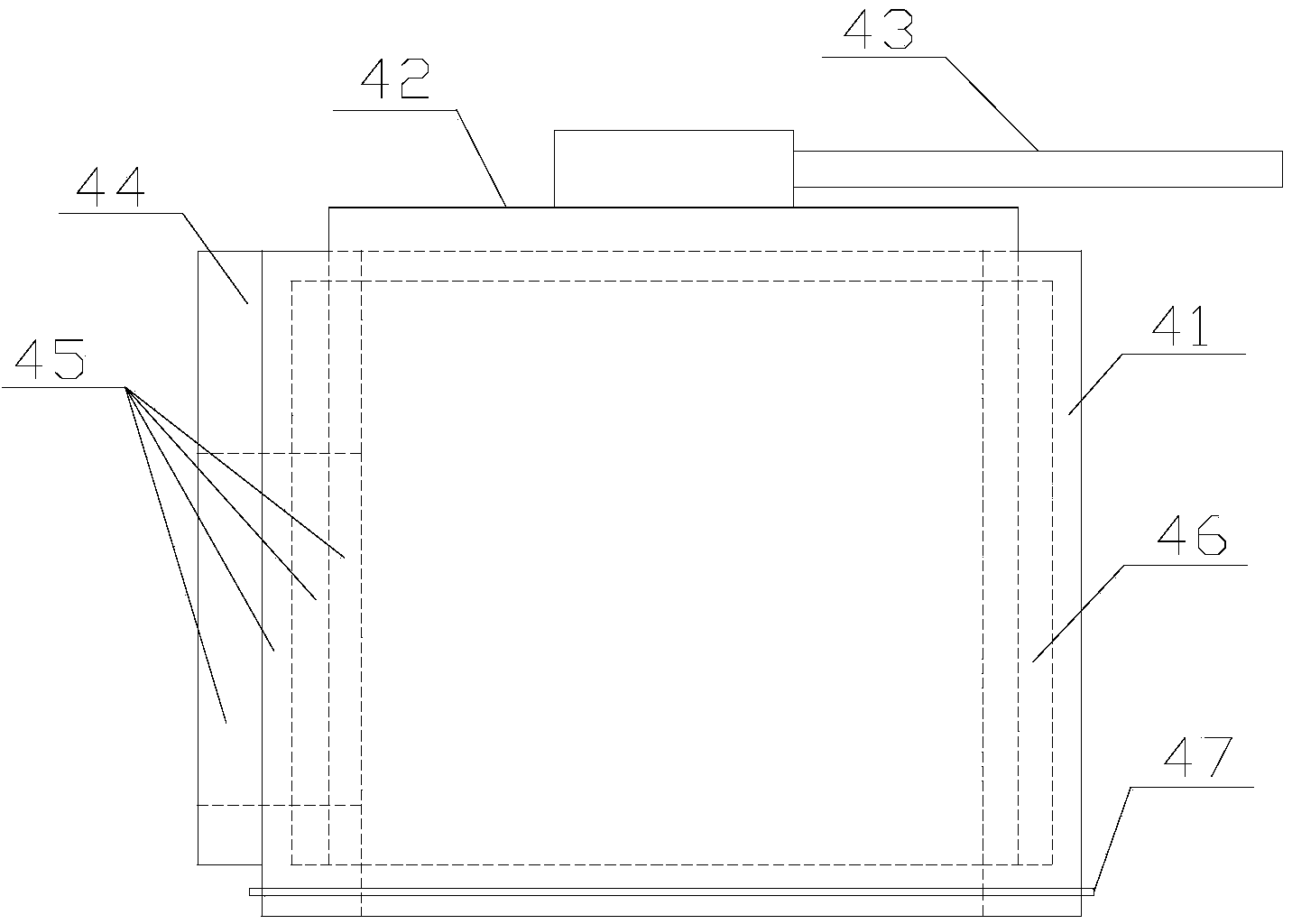

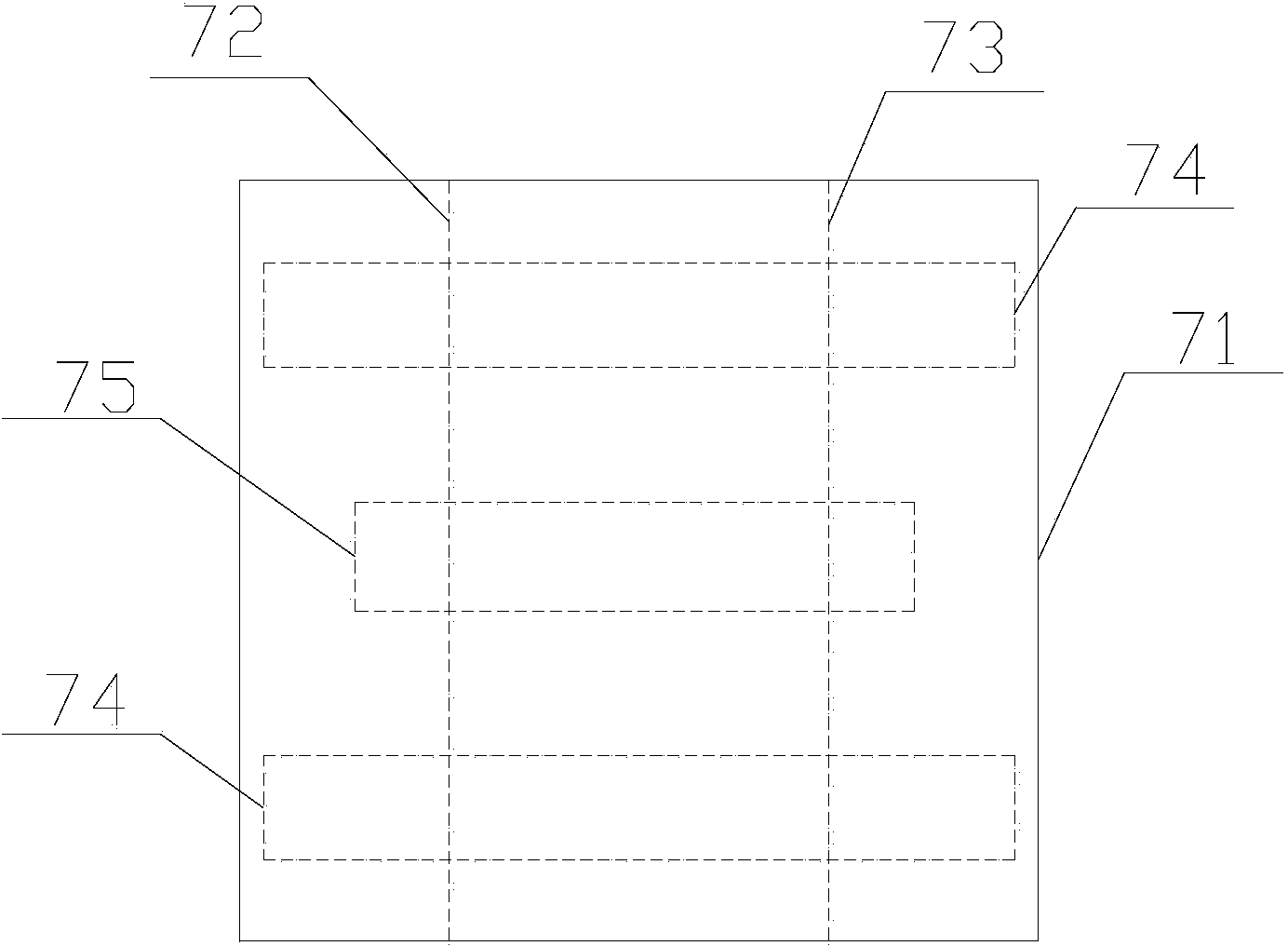

[0022] refer to figure 1 , figure 2 , image 3 with Figure 4 , a barrel of a multifunctional hot-melt rubber powder mixing mixer according to the present invention, including a barrel body 51, a barrel cover 52 matched with the barrel body 51, a lock 53, an observation hole 54, a protective sheet 55, a hinge 56, and a discharge port 4 With the magnet frame 7, the cylinder body 51 is connected with the cylinder cover 52 through a connecting body 56, an observation hole 54 is provided in the middle of the cylinder cover 52, and a protective sheet 55 is provided on the observation hole 54, and the cylinder cover The edge of 52 is provided with lock catch 53, and described lock catch 53, observation hole 54 and hinge 56 are arranged on the same straight line, and the through hole that cooperates with stirring shaft is provided in the middle of the bottom of described cylinder body 51, and described cylinder body 51 is provided with a discharge port 4, the outlet of the discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com