Anhydrous clay production technology and manufacturing equipment applied to same

A technology of waterless clay and clay machine, which is applied in the direction of manufacturing tools, auxiliary molding equipment, supply devices, etc., and can solve the problems of inconvenient packaging, waste, uneven section of clay strips, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

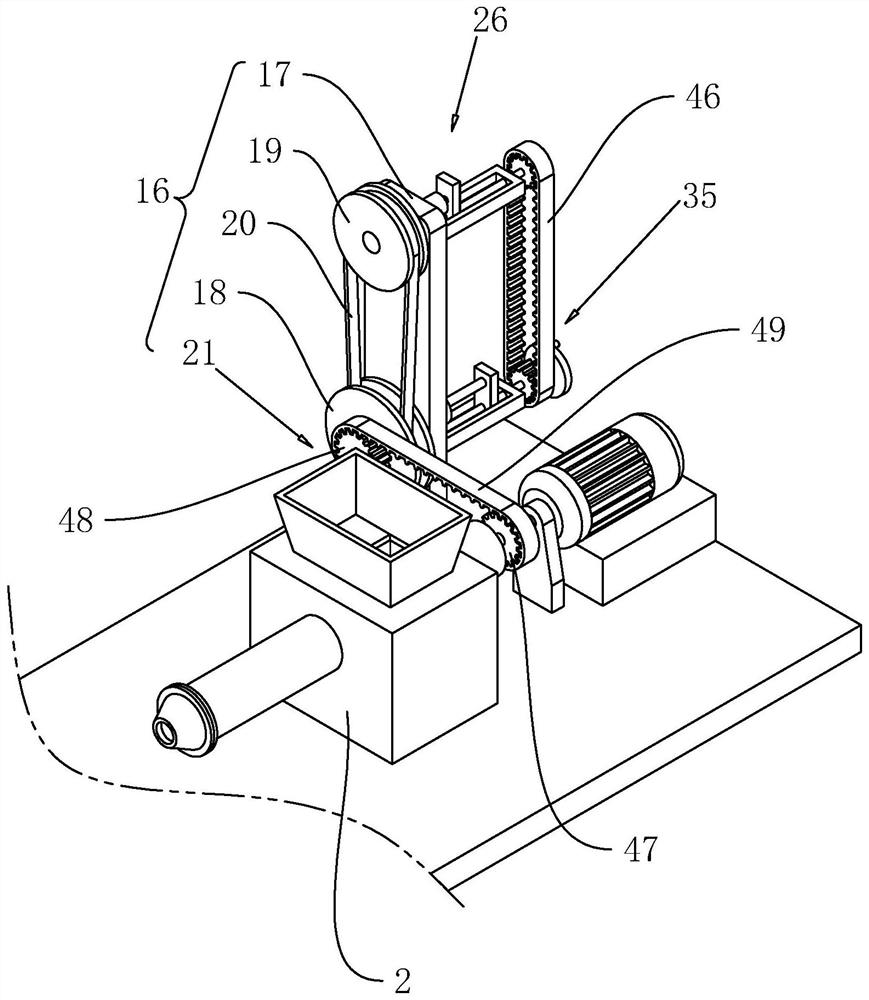

[0038] The following is attached Figure 1-4 The application is described in further detail.

[0039] The embodiment of the present application discloses a waterless taphole clay production process and manufacturing equipment used in the process.

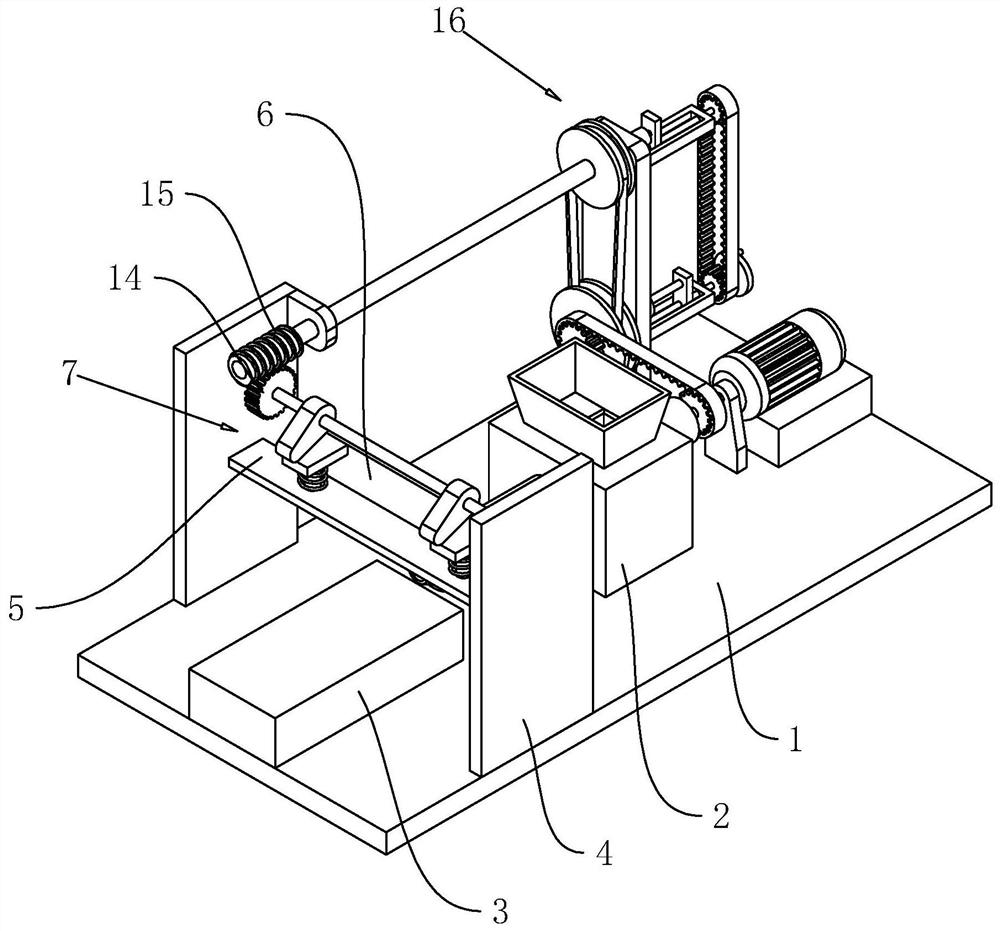

[0040] refer to figure 1 , a kind of waterless gun mud production machine, comprising a body 2, the body 2 is fixed on the bottom plate 1, the bottom plate 1 is locked on the ground of the factory area by bolts, and the mud outlet of the body 2 is provided with a discharge platform 3 , the discharge table 3 is provided with a conveyor belt without a power source, and the formed clay bars are transported in a direction away from the machine body 2 through the conveyor belt.

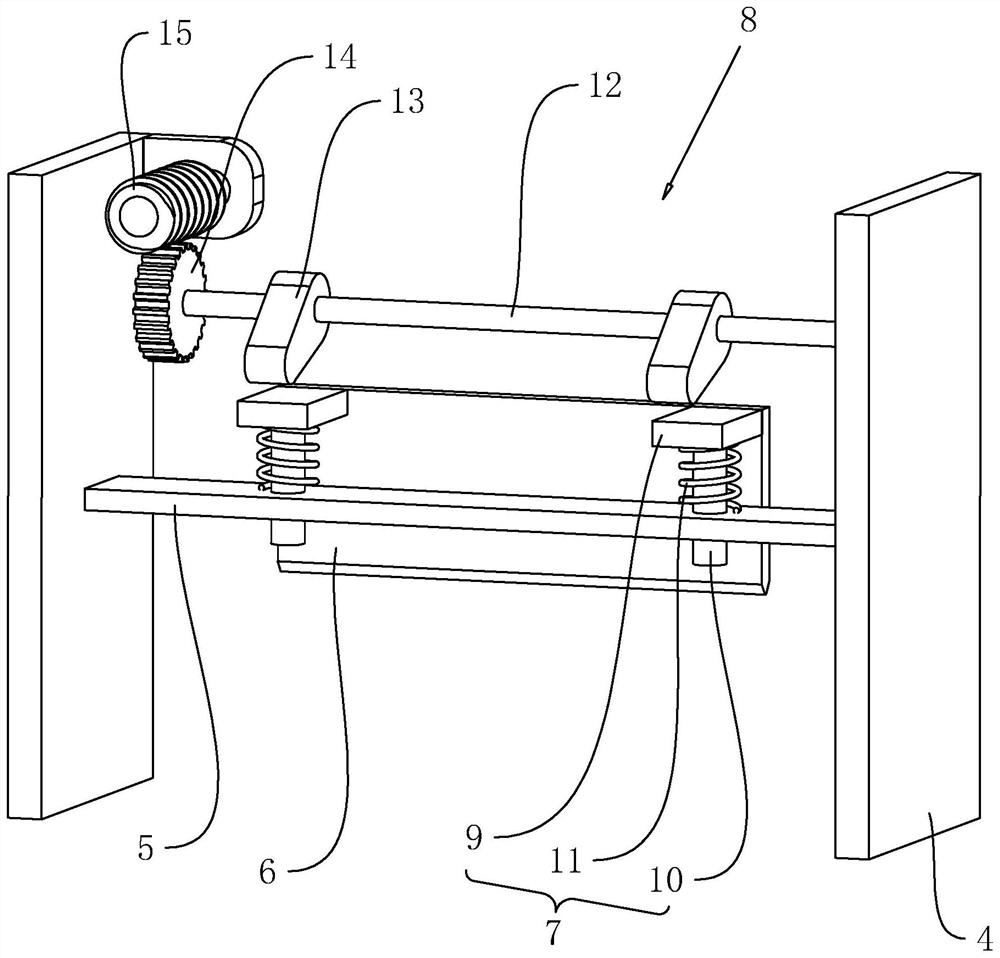

[0041] refer to figure 1 , both sides of the discharge platform 3 are provided with a first mounting plate 4, the first mounting plate 4 is vertically arranged, and a second mounting plate 5 is arranged between the two first mounting plates 4, and the second ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap