Automatic edge removing machine

An edge removal machine and automatic technology, applied in the direction of stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of not fast enough cutting, not so high, and the efficiency can not keep up with the demand, so as to simplify the cutting operation steps and avoid Cutting operation, the effect of improving effective work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] see Figures 1 to 14 As shown, the present invention provides a technical solution: an automatic edge removal machine, comprising:

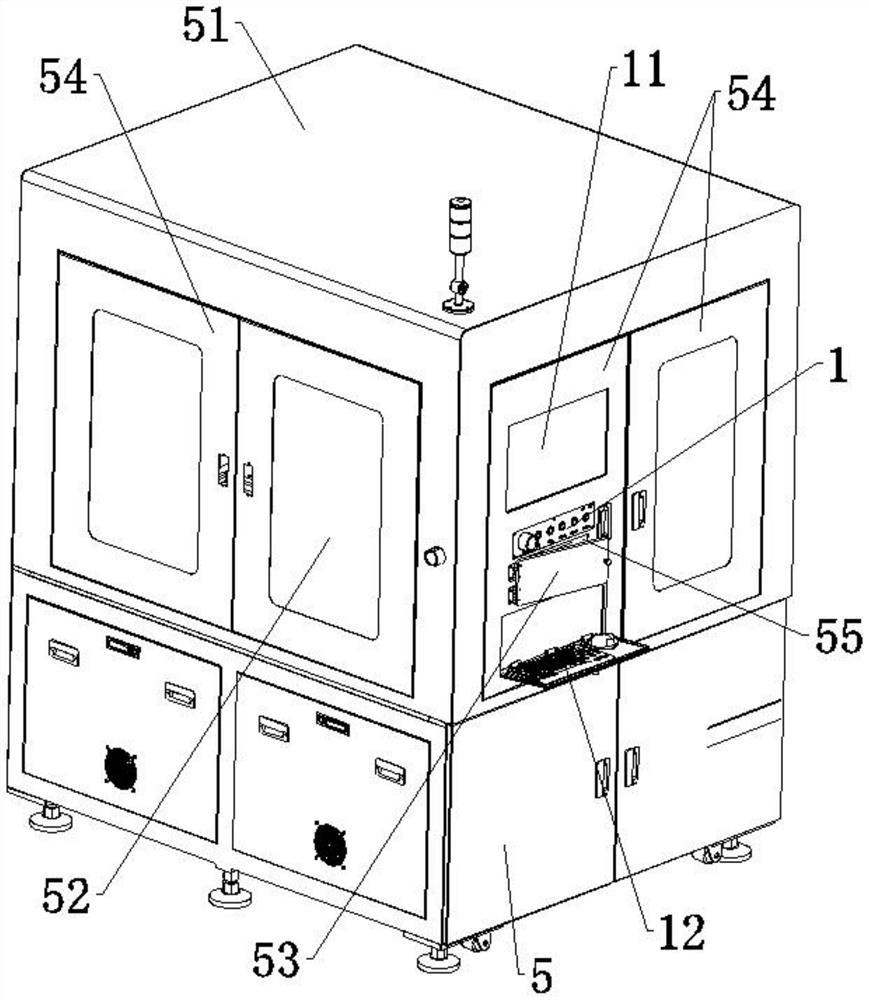

[0049] The frame platform 5 is erected stably on a plane, and a protection cabinet 51 is fixed above it, and cabinet doors 54 are arranged on four sides of the protection cabinet 51, and observation windows 52 are inlaid on each of the cabinet doors 54, one of which A material extraction port 55 is provided on the cabinet door 54, and a material extraction cover 53 that can be opened is locked on the material extraction port 55;

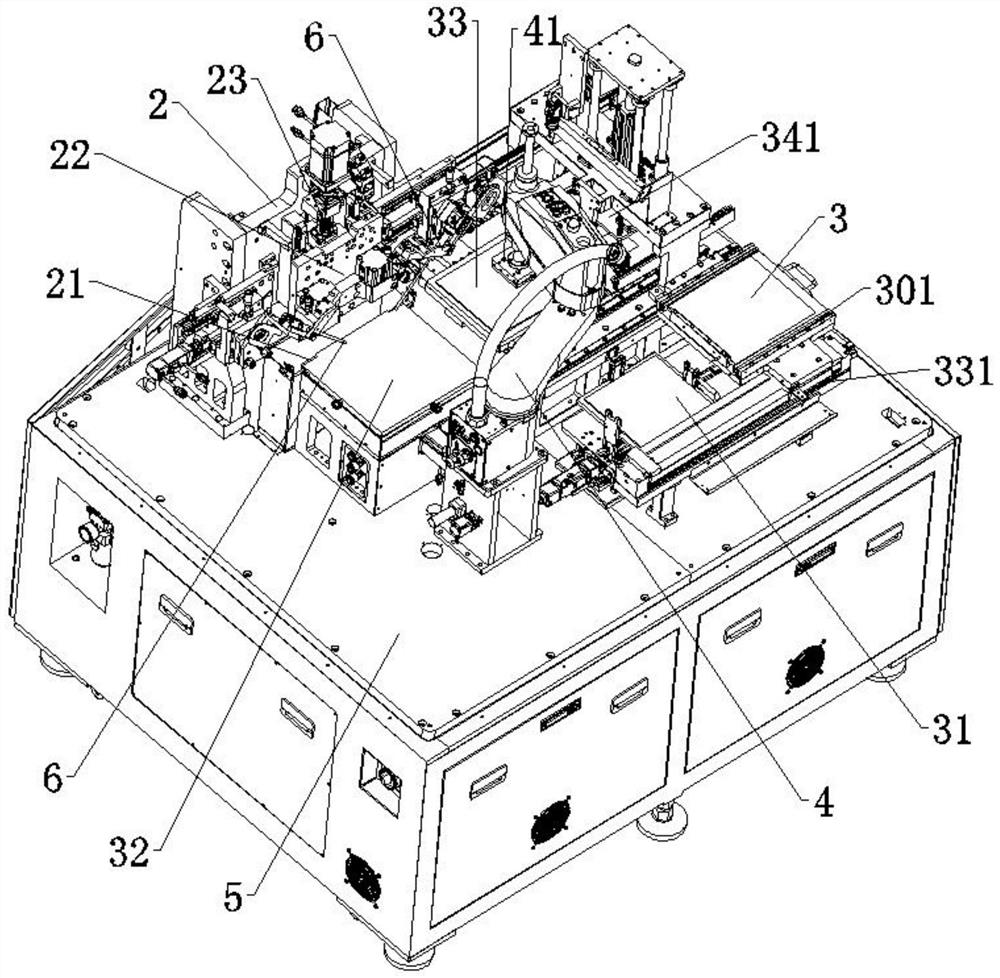

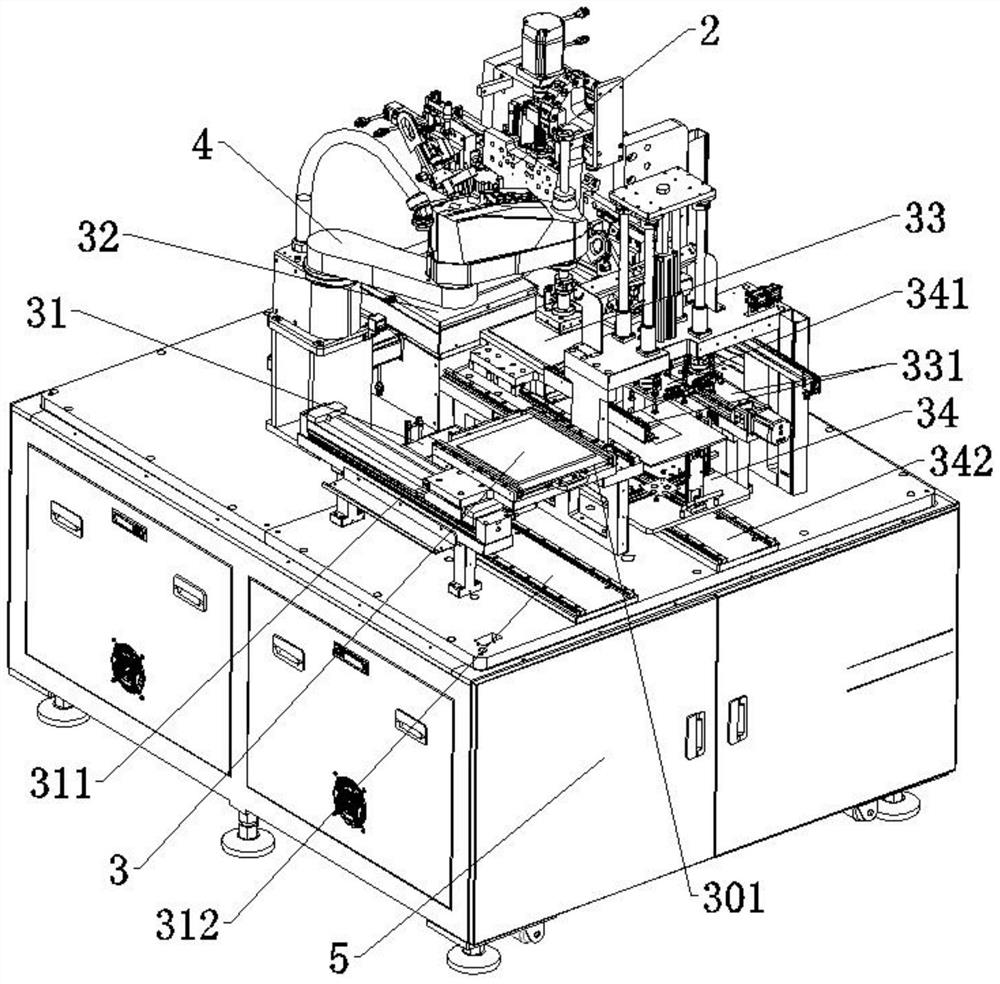

[0050] The mechanical arm 4 is fixedly installed on the frame table 5, and its clamping end is a mechanical arm suction cup 41;

[0051] The waste table 3, the finished product table 31, the cutting table 32, the feeding table 33 and the raw material bin 34 are all arranged inside the protection cabinet 51, and the waste table 3 is installed on the waste positioning slide rail 311 through the waste slide rail 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com