Foaming box

A box-body, integrated technology, applied to conveyor objects, household components, household appliances, etc., can solve the problems of unreasonable structural design of turning equipment, easy collision of boxes, and installation on the back or bottom of electrical appliances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

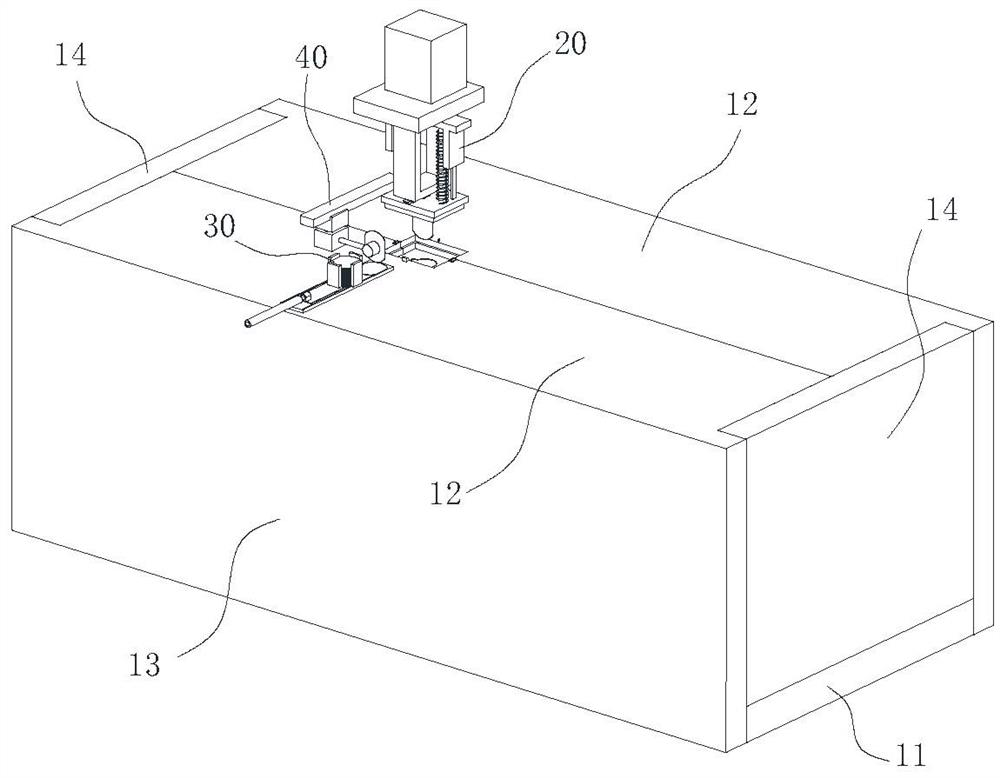

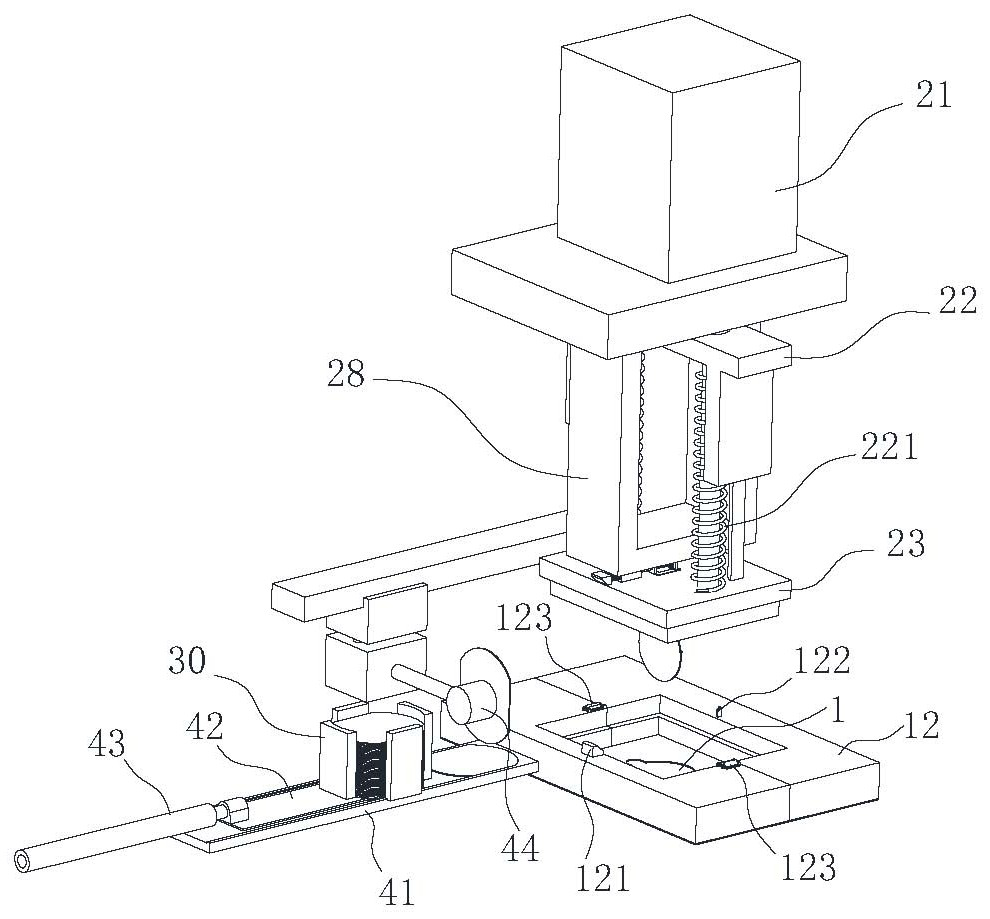

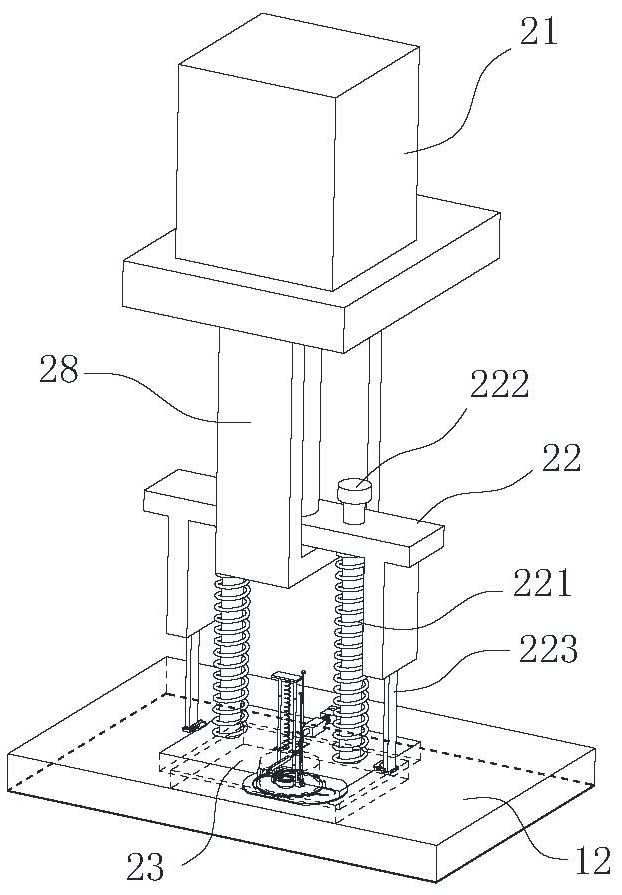

[0052] A box body foaming system includes a foaming device and a cleaning device, and a box conveying line is arranged between the foaming device and the cleaning device; figure 1 As shown, the foaming device includes a foaming mold, and the foaming mold includes a top plate 12, a bottom plate 11, two end plates 14, two side plates 13 and a mold core, wherein the top plate 12 is parallel to the bottom plate, and the two end plates 14 are parallel to each other. The two side plates 13 are parallel to each other, and the top plate 12, the bottom plate 11, the two end plates 14, and the two side plates 13 jointly form a rectangular cavity. The mold core is fixed on the bottom plate 11, and the two side plates 13 and the bottom plate 11 wherein The two opposite sides are hinged, and the other two opposite sides of the two end plates 14 are hinged with the bottom plate 11; The plate 13 is fixedly connected; a gap is provided at the joint where the two halves of the top plate 12 are...

Embodiment 2

[0063] A kind of foam box body, adopts the system described in embodiment 1 to make, and manufacturing method is:

[0064] Step 1: Fix the inner tank and the outer shell of the box into one body, so that the outer shell and the inner tank travel in a closed cavity; and reserve a pouring hole 2 for pouring foaming agent on the outer shell;

[0065] Step 2: Put the foaming agent pouring hole 2 of the box upwards and place it in the foaming mold; before placing the box, first unfold the side plate 13 and the end plate 14 of the mold, and then set the box on the mold core, Then the side panels 13 and the end panels 14 are brought together, and clamps are used to clamp the seams of the panels; on the top panel 12, a gap is reserved for pouring foaming agent and installing the sealing sheet 1, which is compatible with the foaming agent. The position of pouring hole 2 is corresponding;

[0066] Step 3: pour the foaming agent from the foaming agent pouring hole 2 to the sandwich cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com