A kind of anti-skid and wear-resistant ceramic roller

A wear-resistant ceramic and roller technology, which is used in transportation and packaging, conveyor objects, cleaning devices, etc., can solve the problems affecting the normal use of the roller, the single function of the ceramic roller, and the falling of the ceramic sheet, so as to improve heating and facilitate cleaning. , the effect of improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

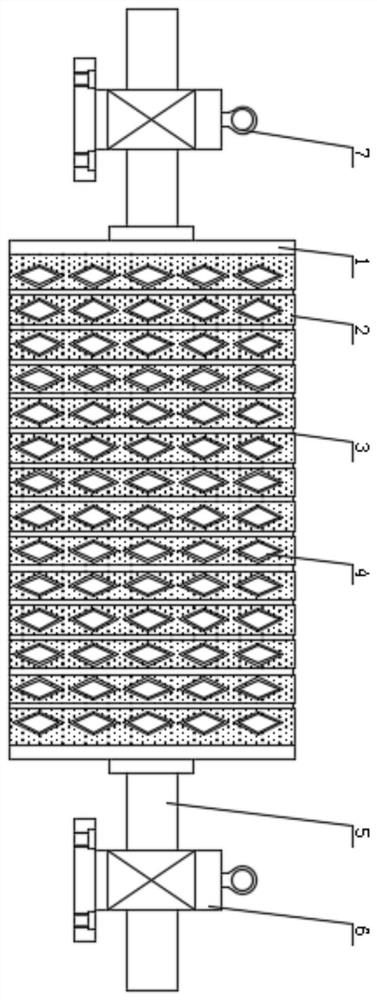

[0042] Embodiment 1, refer to figure 1 , 5 , 6, 7, 8 and Figure 9 , an anti-skid and wear-resistant ceramic roller, comprising a roller body 1, one end of the roller body 1 is provided with a fixing groove 26, one end of the roller body 1 is provided with a cover plate 20, and the cover plate 20 is fixed with the roller body 1 through the fixing groove 26, and the cover plate A heat-conducting cylinder 22 is installed on the surface of one side of the heat-conducting cylinder 22, a mounting groove 23 is provided on the outer surface of the heat-conducting cylinder 22, a heating wire 24 is installed inside the installation groove 23, a through hole 25 is opened on the outer surface of the heat-conducting cylinder 22, and a fan 27 is installed inside the heat-conducting cylinder 22. , the surface of the fixing groove 26 and the cover plate 20 is provided with a second fixing hole 21, the cover plate 20 is fixed with the fixing groove 26 through the second fixing hole 21 throug...

Embodiment 2

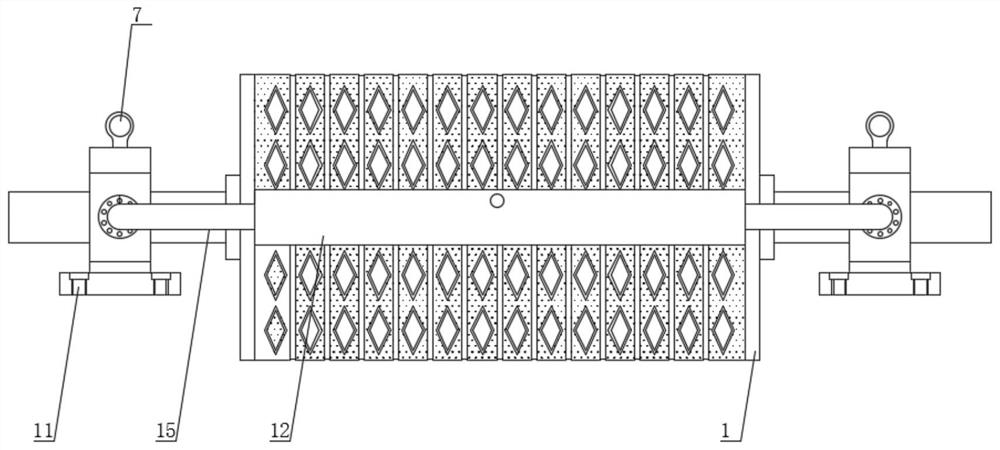

[0043] Embodiment 2, refer to figure 1 , 3 and Figure 4 , a bearing seat 6 is installed on the surface of the transmission shaft 5, an electric telescopic rod 14 is provided on one side of the two bearing seats 6, and a connecting rod 15 is provided at one end of the electric telescopic rod 14, and a cleaning plate 12 is arranged between the connecting rods 15. The cleaning plate A brush 17 is provided below the surface of the 12, the surface of the cleaning plate 12 is located above the brush 17 and a shunt pipe 16 is installed, the surface of the shunt pipe 16 is provided with a high-pressure nozzle 18, and one end of the shunt pipe 16 penetrates the surface of the cleaning plate 12. When the surface of the drum needs to be cleaned, the staff starts the electric telescopic rod 14 through the controller 30, and then the electric telescopic rod 14 drives the cleaning plate 12 to move through the connecting rod 15, and then the brush 17 and the surface of the drum body 1 are ...

Embodiment 3

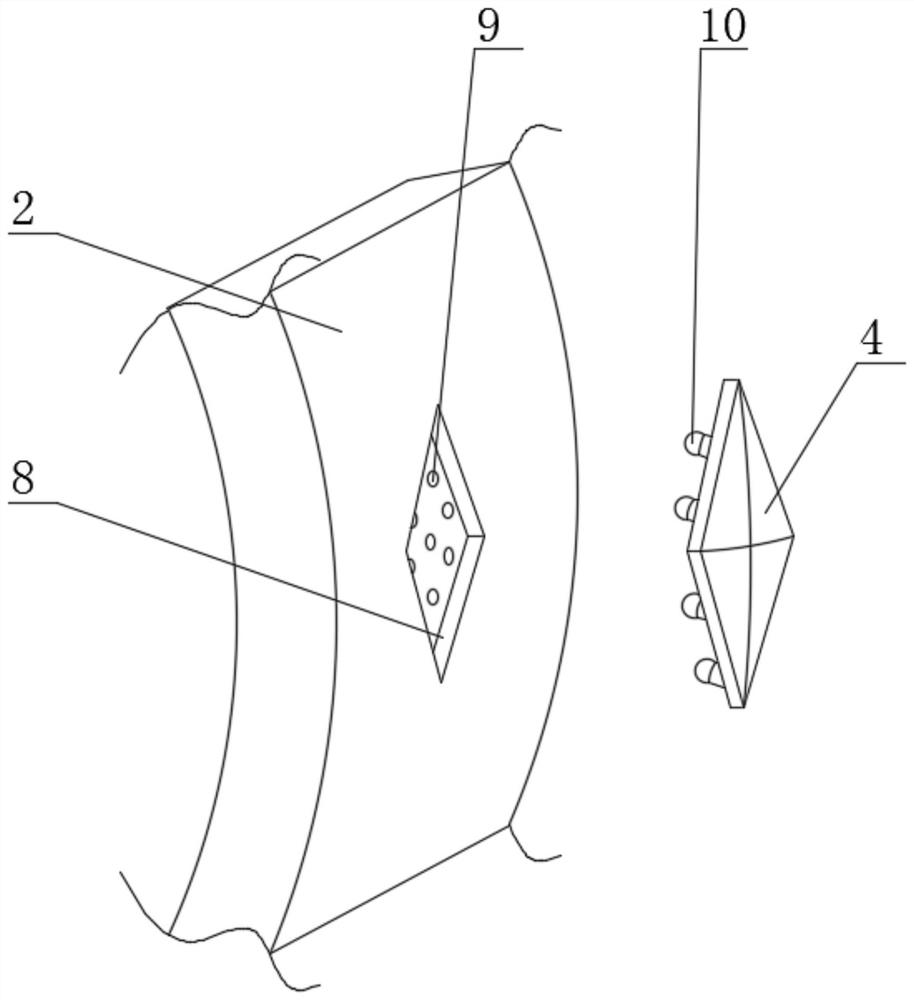

[0044] Embodiment 3, refer to figure 1 and figure 2 , the surface of the drum body 1 is sleeved with the rubber sleeve 2, the outer surface of the rubber sleeve 2 is provided with a card slot 8, the inside of the card slot 8 is clipped with a ceramic sheet 4, the inner wall surface of the card slot 8 is provided with a limit hole 9, and one side of the ceramic sheet 4 is provided Limiting ball 10, the limiting ball 10 is in interference fit with the limiting hole 9, the outer surface of the rubber sleeve 2 is provided with a cleaning groove 3, a plurality of ceramic sheets 4 are provided, and the plurality of ceramic sheets 4 are equidistantly installed on the rubber sleeve. 2. On the outer surface, the ceramic sheet 4 is clamped with the rubber sleeve 2 through the card slot 8. At the same time, a limit hole 9 is arranged on the inner wall surface of the card slot 8, and a limit ball 10 is arranged on one side of the ceramic sheet 4, which passes through the limit hole. 9 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com