Automatic centering and overturning mechanism for cover plate glass

A technology of cover glass and turning mechanism, which is applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., and can solve problems such as cumbersome manual operations, damage to cover glass, and decline in product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

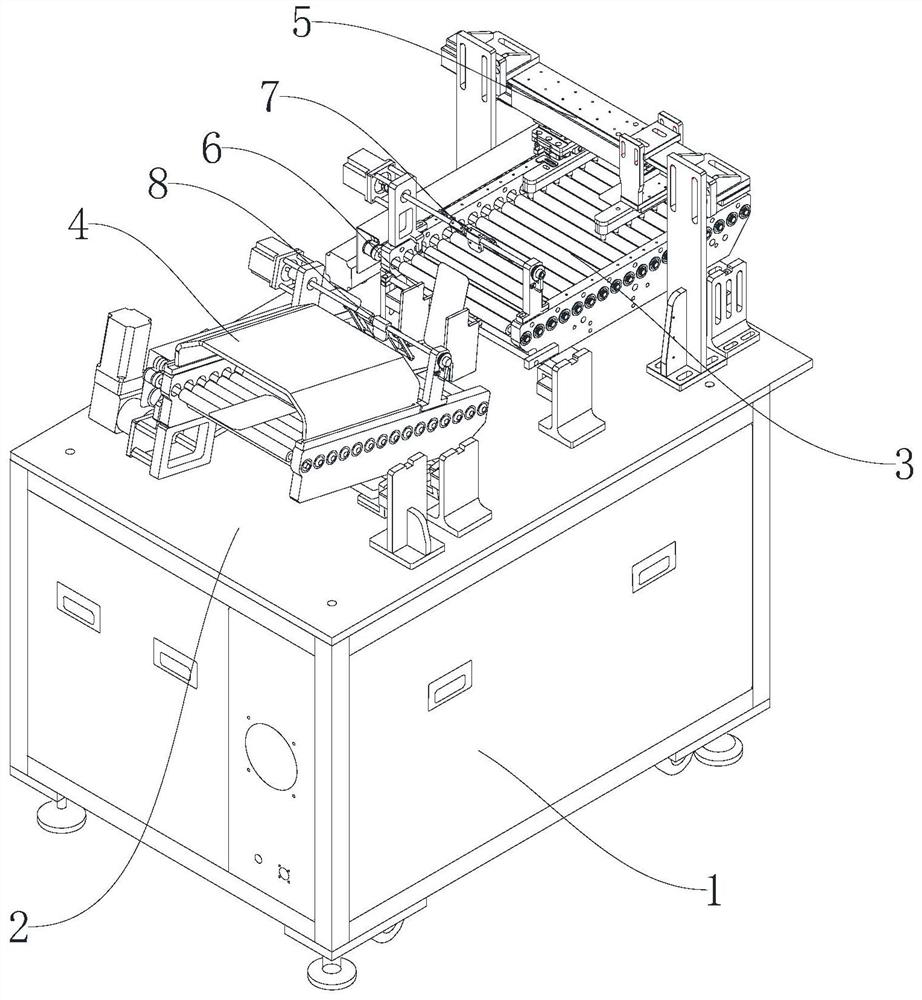

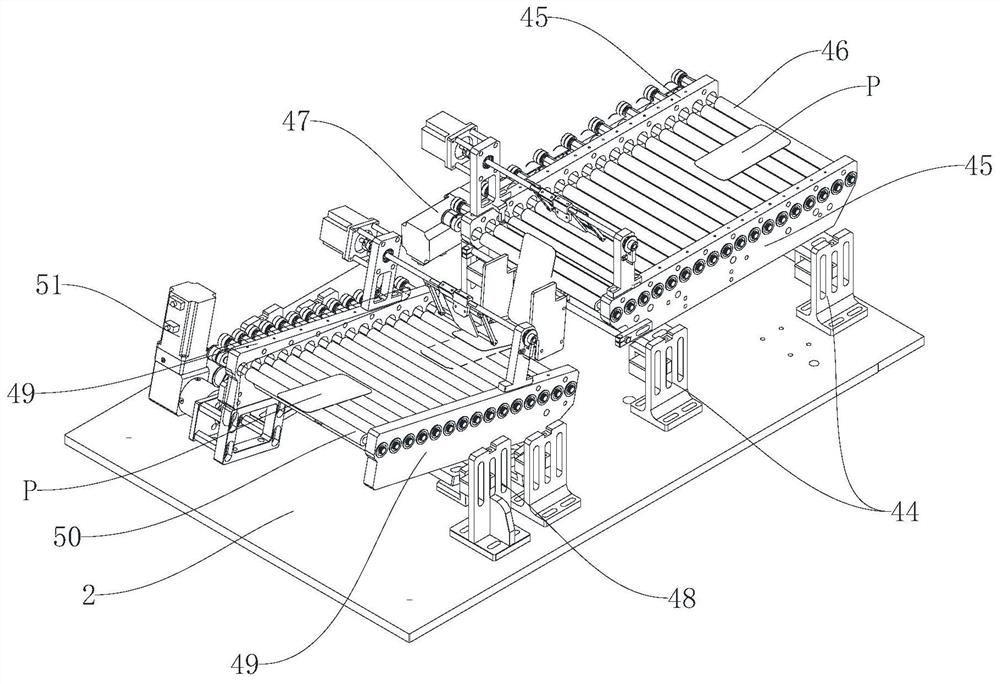

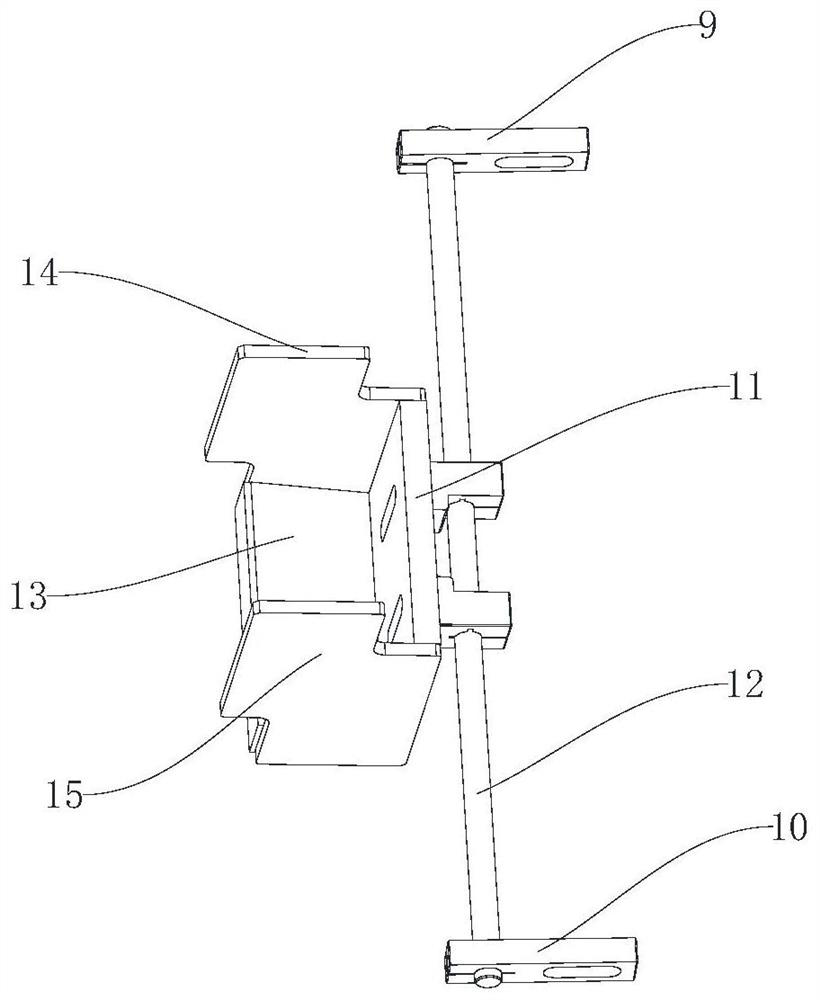

[0020] Example: such as figure 1 As shown, an automatic centering and turning mechanism for cover glass, including a lower bracket 1, a table panel 2, a turning and feeding mechanism 3, a turning and lifting conveying mechanism 4, a product centering mechanism 5, and a turning and receiving adjustment mechanism 6 and two turning and pushing mechanisms, the lower bracket 1 is fixed between the cleaning process and the testing process of the cover glass production line, the table panel 2 is installed on the lower bracket 1, the turning feeding mechanism 3 and the turning lifting conveying mechanism 4 are respectively Fixed on the table panel 2, the turning feeding mechanism 3 is located at the discharge end of the cleaning machine set at the cleaning process. After the cover glass comes out of the washing machine, it will enter the turning feeding from the feeding end of the turning feeding mechanism 3 In the feeding mechanism 3, the product centering mechanism 5 is fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com