Continuous gilding paper attaching device for garment hang tag processing

A bronzing paper and tag technology, applied in lamination devices, display devices, transportation and packaging, etc., can solve the problems of bronzing paper easily scratching hands, affecting the appearance of the tag, and easily wrinkling bronzing paper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

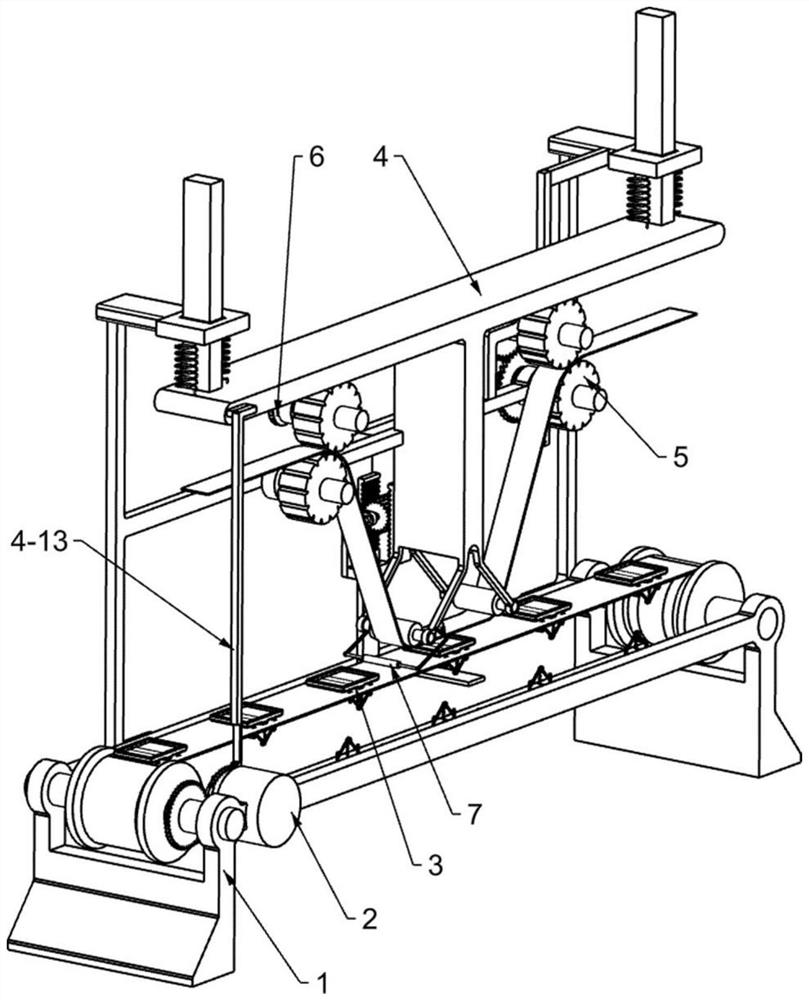

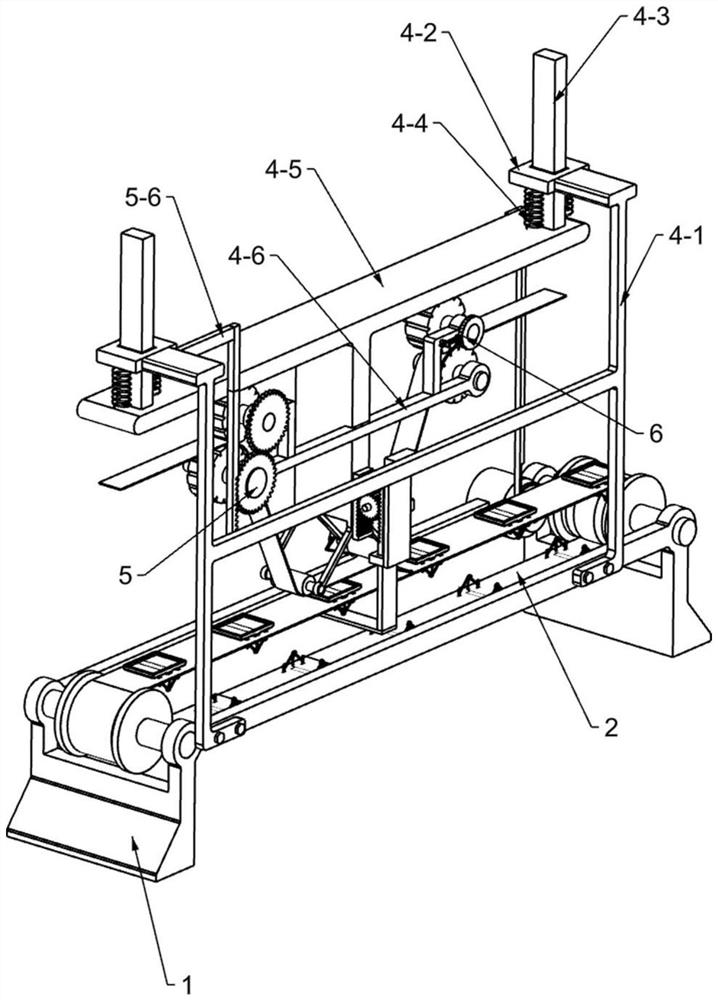

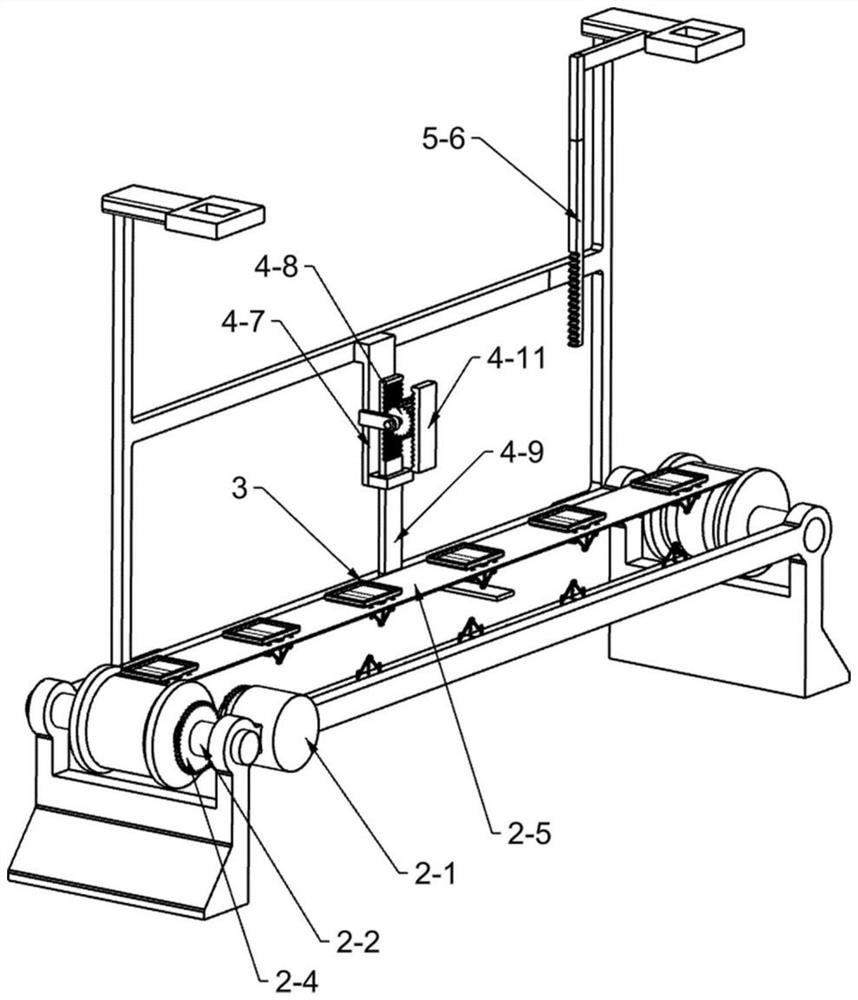

[0031] A continuous bronzing paper attaching device for garment tag processing, such as Figure 1-12 As shown, it includes a support 1, a driving mechanism 2, a lifting mechanism 4, a transmission mechanism 5 and a bronzing paper limiting mechanism 6. A driving mechanism 2 is installed on the support 1, and the driving mechanism 2 is used for intermittently conveying tags. Twelve shearing mechanisms 3 are installed. The shearing mechanisms 3 are used to cut off the bronzing paper. One side of the support 1 is equipped with a lifting mechanism 4. The lifting mechanism 4 is used to drive the bronzing paper to be attached to the tag. The lifting mechanism 4 A transmission mechanism 5 is installed, and the transmission mechanism 5 is used for clamping and pulling out the bronzing paper, and a bronzing paper restricting mechanism 6 is installed on the conveying mechanism 5, and the bronzing paper restricting mechanism 6 is used for preventing the bronzing paper from loosening.

[0...

Embodiment 2

[0044] On the basis of Example 1, such as Figure 13 Shown, also include hold-down mechanism 7, hold-down mechanism 7 is installed on the elevating mechanism 4, hold-down mechanism 7 includes swing lever 7-1, torsion spring 7-2 and hold-down wheel 7-3, near guide The lifting frame 4-5 both sides of wheel 4-51 is all rotatably connected with swing bar 7-1, is connected with torsion spring 7-2 between swing bar 7-1 and lifting frame 4-5, and swing bar 7-1 end A pinch wheel 7-3 is connected between the parts.

[0045] When the conveyor belt 2-5 intermittently conveys the tag through the rotation of the pulley 2-2, the tag attached with hot stamping paper will be transported to contact with the pressing wheel 7-3 and continue to be transported, and the swing rod 7-1 will swing outward , the torsion spring 7-2 is compressed, and the pressing wheel 7-3 will roll on the hot stamping paper attached to the hang tag. In this way, the hot stamping paper can be better attached to the han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com