Device system and method for cooling CDON mixture prepared through dehydrogenation of CDOL

A reaction mixture, catalytic dehydrogenation technology, applied in the direction of dehydrogenation preparation, chemical instruments and methods, separation/purification of carbonyl compounds, etc., can solve the problems of increased floor area of separation devices, obvious energy consumption, high total investment, etc. Achieve the effect of reducing investment in fixed assets, improving economy and avoiding losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

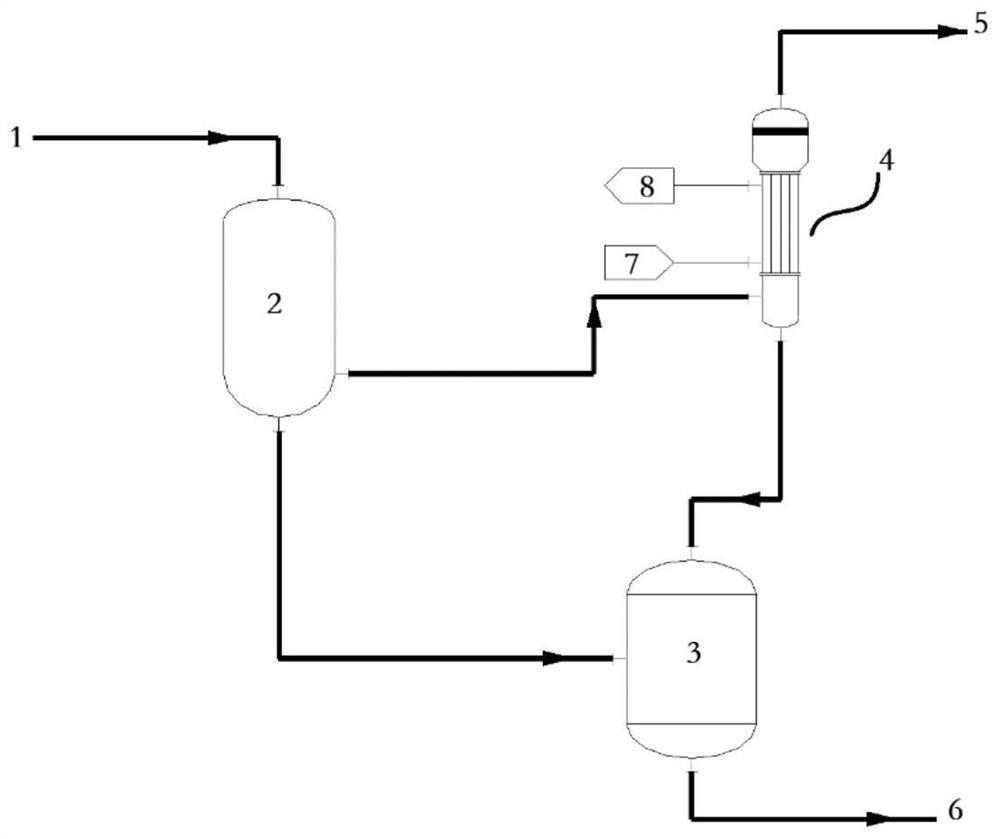

[0051] according to image 3 In the process shown, the gas phase at the outlet of the dehydrogenation reactor enters the reaction gas phase condenser from bottom to top. The hydrogen and inert gases generated by the reaction enter the downstream process from the top of the gas phase condenser. After cooling, the liquid-phase process material is obtained, and the liquid-phase process material is refluxed by gravity in the heat exchange tube, and contacts and exchanges heat with the gas phase at the inlet in the heat exchange tube filled with stepped ring fillers to reduce energy consumption. The liquid phase flows to the buffer tank of the reaction solution. The process parameters of the above process are: annual output of CDON is 80,000 tons (annual operating time is 8000 hours), the outlet process control temperature of the dehydrogenation reactor is 250°C, the pressure is 100kPaA, the amount of inert carrier gas used in the dehydrogenation reactor is the same as that of CDO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com