High-strength alloy structural steel for hydraulic cylinder of fracturing pump and preparation method thereof

A high-strength alloy and fracturing pump technology, applied in the field of machinery manufacturing equipment, can solve problems affecting shale gas mining operations, poor reliability, and low service life, so as to avoid cracking failures and production accidents, and reduce labor costs and time Cost, the effect of reducing the cost of use

Inactive Publication Date: 2021-03-16

江苏艾福泰克能源装备有限公司

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, most domestic fracturing pump cylinders use 34CrNi 3 MoE, 34CrNi 3 Mo is a high-strength alloy structural steel, which is widely used in the whole forging low-pressure rotor steel of large steam turbines. It has good comprehensive mechanical properties and process properties, and has been widely used in the production of engine rotors and steam turbine impellers. During the fracturing process, especially the fracturing operation of shale gas exploitation, it is subjected to high pressure of 80-105MPa and repeated actions every 100-200 times per minute, which is prone to fatigue, resulting in fatigue damage to the hydraulic cylinder, cracking and failure of the inner cavity , the hydraulic cylinder made of this material has low service life and poor reliability. The average life span is about 100-200 hours under medium and low pressure (60-80MPa) conditions; under high pressure (80-105MPa), it cannot even complete a mouthful The operation of the well (about 10 hours) needs to be shut down for replacement. If it cracks and fails during the operation, it may even lead to a production accident and seriously affect the shale gas exploitation operation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0021]

[0022]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

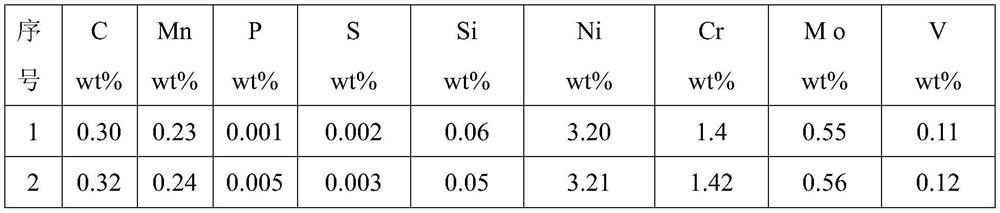

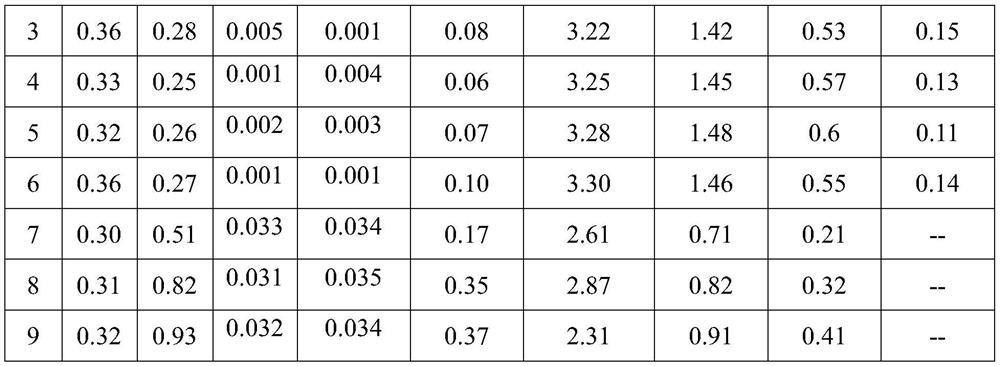

The invention provides high-strength alloy structural steel for a hydraulic cylinder of a fracturing pump. The steel comprises the following chemical elements in percentage by weight: 0.30-0.36% of C,0.23-0.28% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.05-0.10% of Si, 3.20-3.30% of Ni, 1.40-1.50% of Cr, 0.55-0.60% of Mo, 0.11-0.15% of V, less than or equal to1.5 ppm of H, less than or equal to 112 ppm of O, less than or equal to 70-120 ppm of N and the balance Fe. Meanwhile, the invention further provides a preparation method of the structural steel, thestructural steel obtained through the preparation method is used for manufacturing a hydraulic cylinder of a fracturing pump, under the severe working condition of shale gas exploitation, the servicelife of the product can be prolonged, the use cost can be reduced, the quality is stable and reliable, unpredictable cracking failure and production accidents in the operation process are avoided, andthe requirements of oil-gas field deep well fracturing and shale gas exploitation are met.

Description

technical field [0001] The invention belongs to the field of mechanical manufacturing equipment for oil and gas field stimulation operations and shale gas exploitation fracturing operations, and particularly relates to a high-strength alloy structural steel for fracturing pump cylinders and a preparation method thereof. Background technique [0002] At present, most domestic fracturing pump cylinders use 34CrNi 3 MoE, 34CrNi 3 Mo is a high-strength alloy structural steel, which is widely used in the whole forging low-pressure rotor steel of large steam turbines. It has good comprehensive mechanical properties and process properties, and has been widely used in the production of engine rotors and steam turbine impellers. During the fracturing process, especially the fracturing operation of shale gas exploitation, it is subjected to high pressure of 80-105MPa and repeated actions every 100-200 times per minute, which is prone to fatigue, resulting in fatigue damage to the hyd...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/02C22C38/04C22C38/44C22C38/46C21D1/25C21D1/26C21D1/28C21D6/00C22C33/04

CPCC21D1/25C21D1/26C21D1/28C21D6/004C21D6/005C21D6/008C22C33/04C22C38/001C22C38/002C22C38/02C22C38/04C22C38/44C22C38/46

Inventor 傅宏伟姜涌郭志军王继旭

Owner 江苏艾福泰克能源装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com