Piston for ignition and compression ignition gasoline engine

A gasoline engine and piston technology, which is applied in the field of ultra-lean combustion, can solve the problems of severely limited compression ratio, inability to meet the requirements of gasoline ignition and compression ignition, and inability to achieve high-efficiency combustion thermal efficiency performance of ignition compression ignition, and achieve the effect of improving thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and examples, but these examples should not be construed as limiting the present invention.

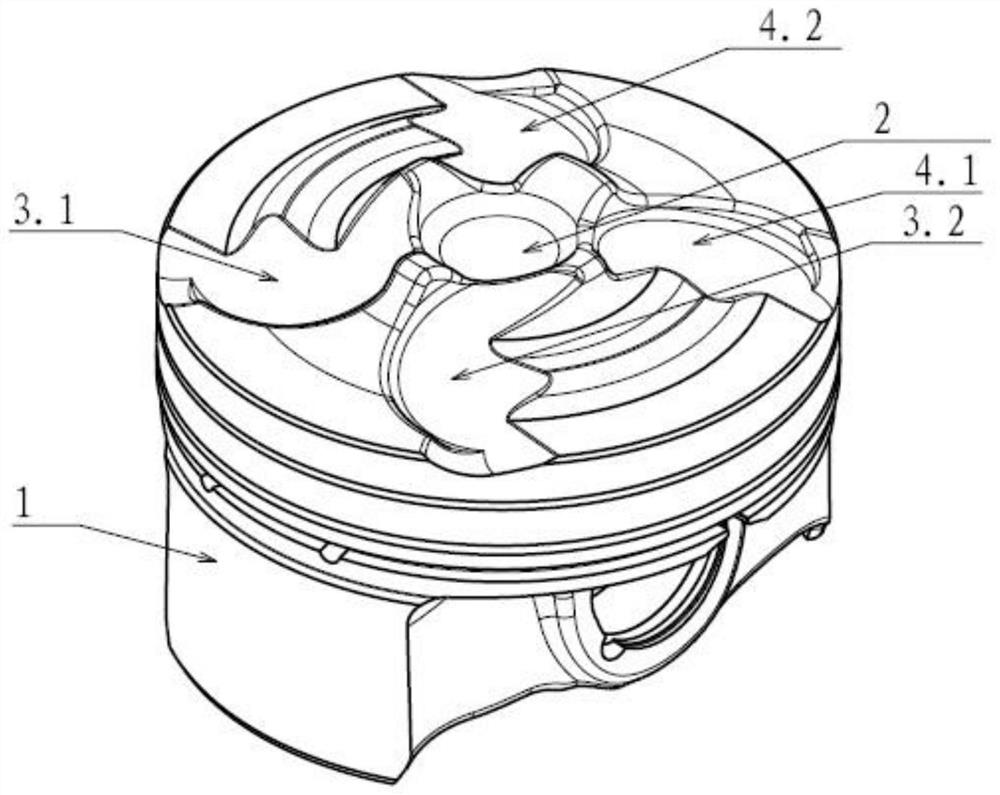

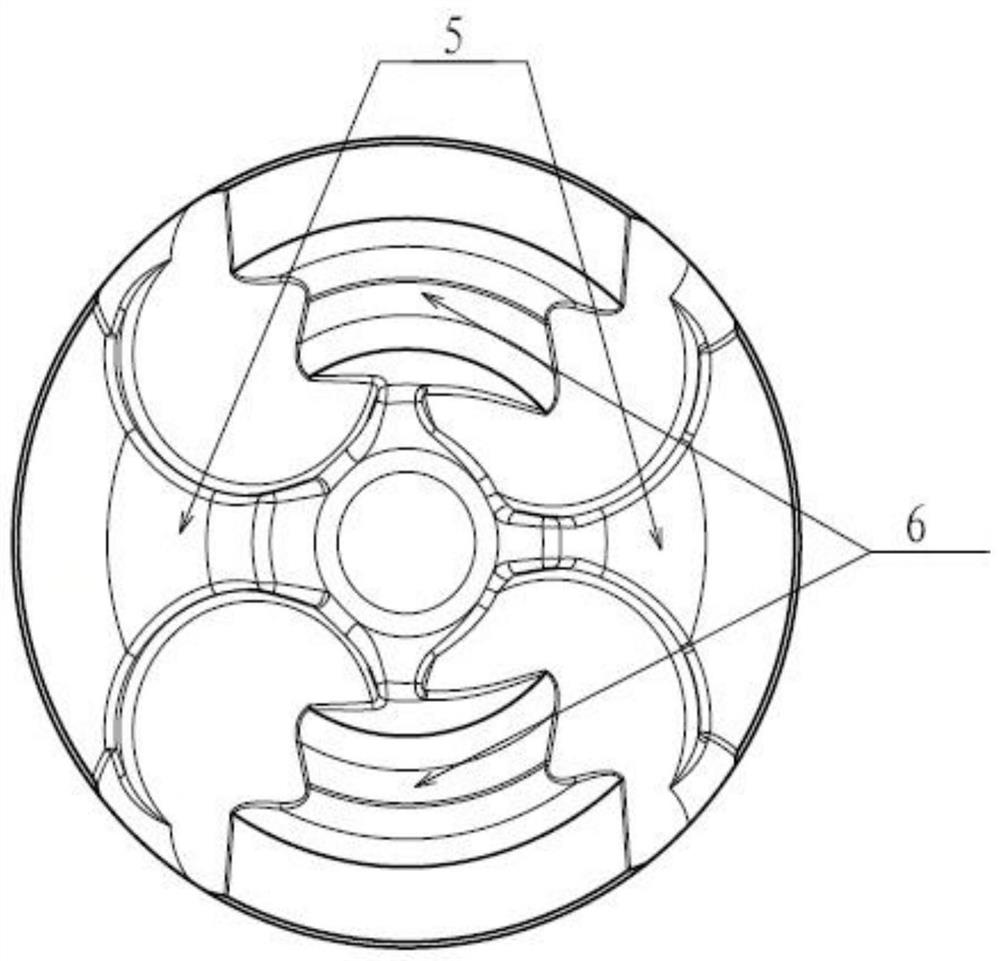

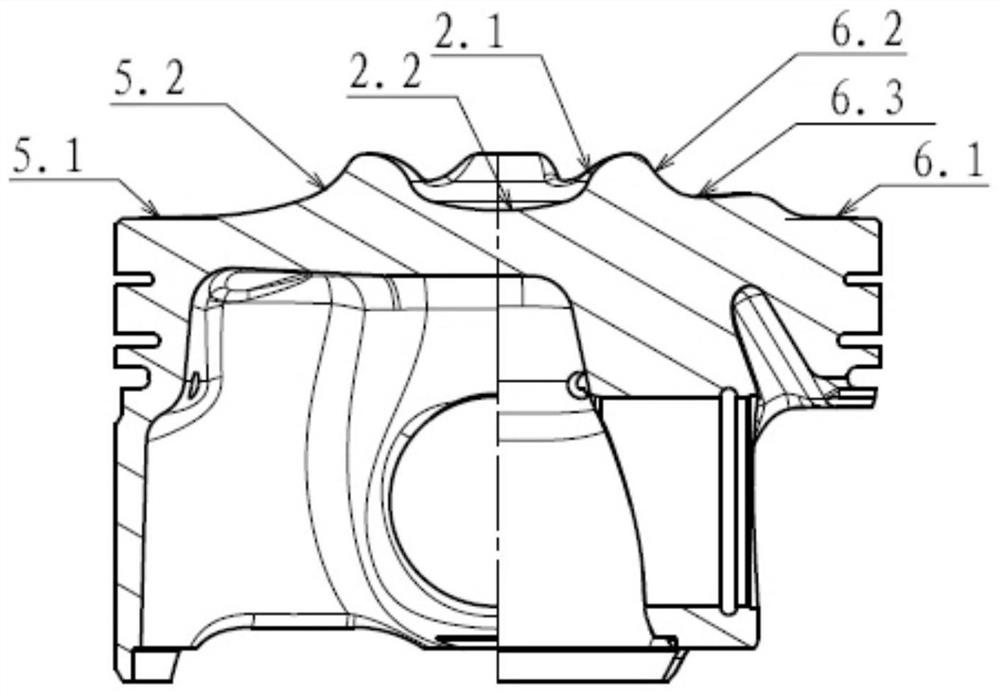

[0035] A piston for ignition compression ignition gasoline engine, comprising a piston body 1, a pit 2, a first intake avoidance pit 3.1, a second intake intake avoidance pit 3.2, and a first exhaust escape pit 4.1 are arranged on the top surface of the piston body 1 and the second exhaust avoidance pit 4.2. The pit 2 is located at the center of the top surface of the piston body 1. The pit 2 includes a side wall 2.1 and a pit bottom 2.2. The pit bottom 2.2 is aligned with the injection direction of the injector oil beam. The avoidance pit 3.1, the second intake avoidance pit 3.2, the first exhaust avoidance pit 4.1 and the second exhaust avoidance pit 4.2 are arranged in sequence along the circumference of the pit 2, the first intake avoidance pit 3.1 and the second intake avoida...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com