Bird impact load testing device and method

A load test and bird strike technology, which is applied in the direction of measuring devices, impact tests, machine/structural component tests, etc., can solve the problem that the sensor cannot be used for static measurement, and achieve the effect of simple structure, easy operation and good maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

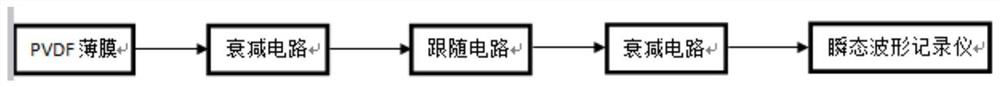

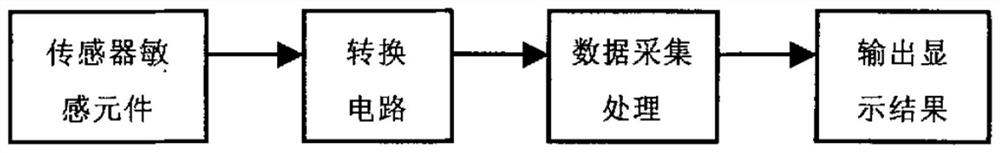

[0023] In order to avoid large errors in the experimental test results in the bird strike test due to temperature factors. This paper presents a simple mechanical device structure.

[0024] A bird strike load testing device according to an embodiment of the present invention, comprising: a support seat, a first elastic component, a bird strike support surface, a second elastic component, a compression measurement support surface, a first chain, a second chain, and a gear mechanism . Ruler, wherein, the support base includes a fixed surface, the fixed surface is a plane in the vertical direction; one end of the first elastic component is fixedly connected to the upper end of the fixed surface; the other end of the first elastic component is fixedly connected to the upper end of the bird impact support surface, the second A chain is fixed at the lower end of the bird impact support surface; one end of the second elastic component is fixedly connected with the lower end of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com