Radial structure overhead line relocation method based on uninterrupted power supply requirements

An overhead line, radial technology, applied in the direction of overhead line/cable equipment, cable laying equipment, energy industry, etc., can solve the problem that mobile power generation vehicles cannot meet user load, affect power supply reliability and power business environment, and user continuity. Problems such as the limitation of power supply scheme, to achieve the effect of low cost, strong applicability and great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

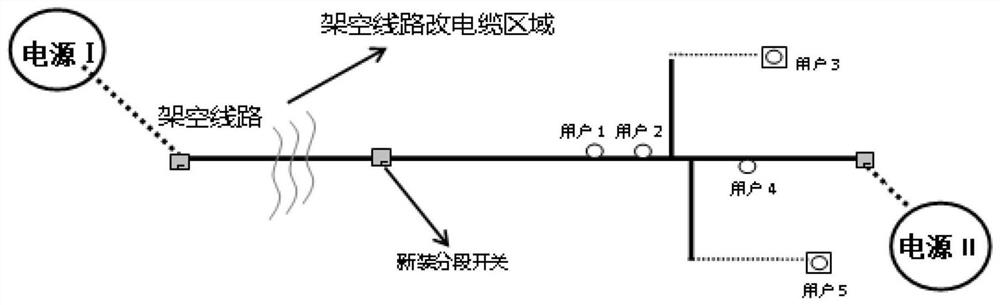

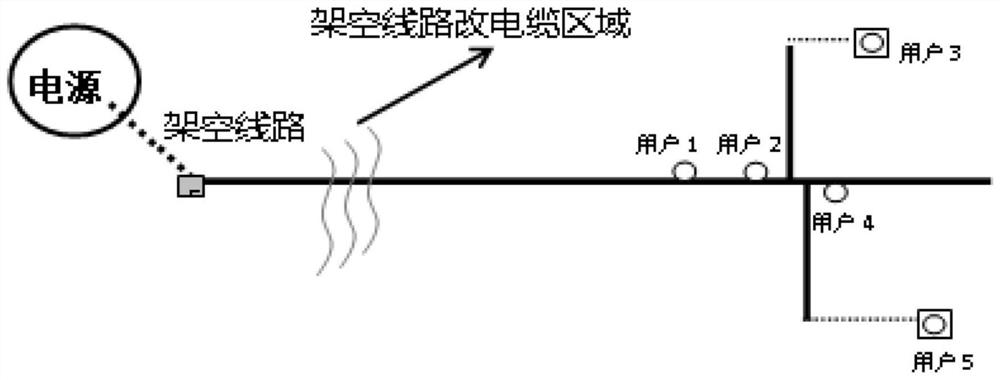

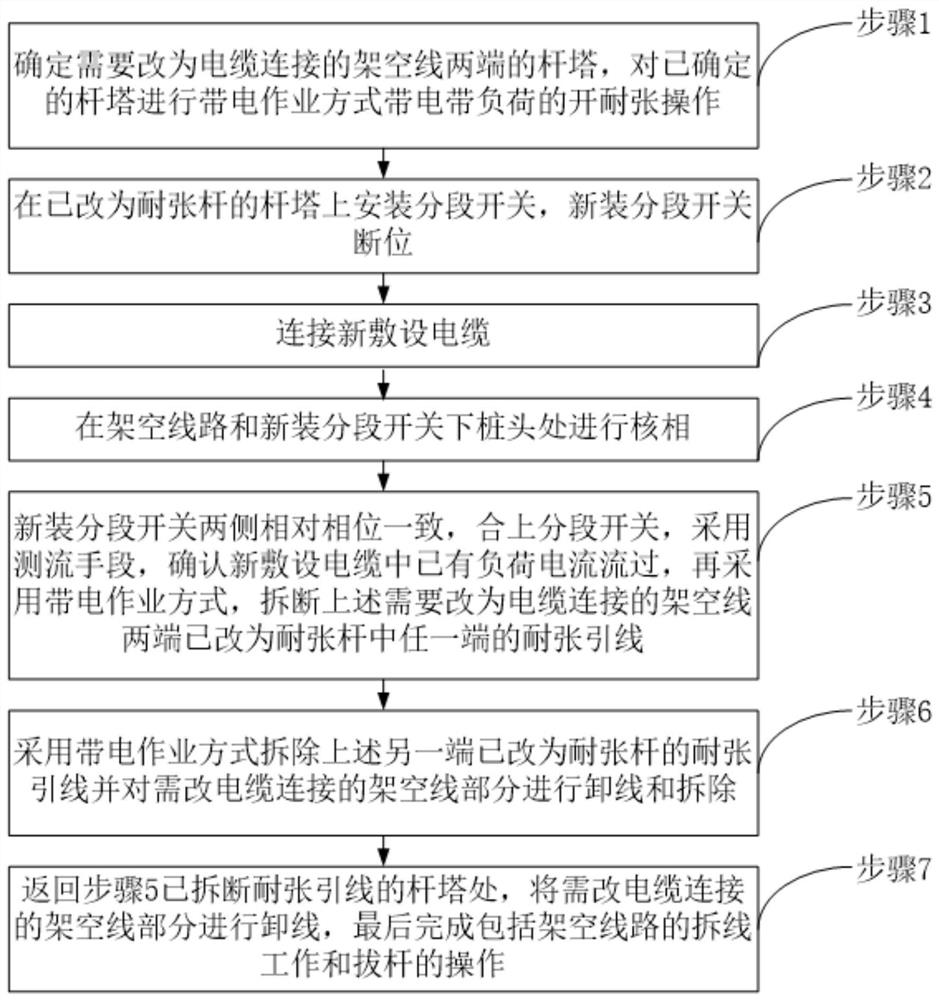

[0041] Specifically, the method for relocating overhead lines in radial structures based on non-stop power requirements, such as image 3 shown, including:

[0042] Step 1, determine the poles and towers at both ends of the overhead line that need to be changed to cable connection, and carry out the opening and tensioning operation of the determined poles and towers in the live work mode with live load;

[0043] Step 2, newly install a section switch for connecting cables on the tower that has been changed to a tension bar, and newly install a section switch to break the position;

[0044] Step 3, connect the newly laid cables by means of live work, one end is connected to the lower pile head of the newly installed section switch, and the other end is lapped to the outside overhead line of the determined tower;

[0045] Step 4, carry out phase verification at the pile head under the overhead line and the newly installed section switch;

[0046] Step 5. Check that the phases ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com