Motor cooling device, motor cooling control method and device and water chilling unit

A technology for motor cooling and control methods, applied in cooling/ventilation devices, electromechanical devices, refrigeration components, etc., can solve problems such as insufficient motor cooling, and achieve the effects of improving stable operation and reliability, avoiding failures and shutdowns, and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046]This embodiment provides a motor cooling device, which is applied to a unit including at least two compressors, and can ensure sufficient cooling of the motor under full-load conditions.

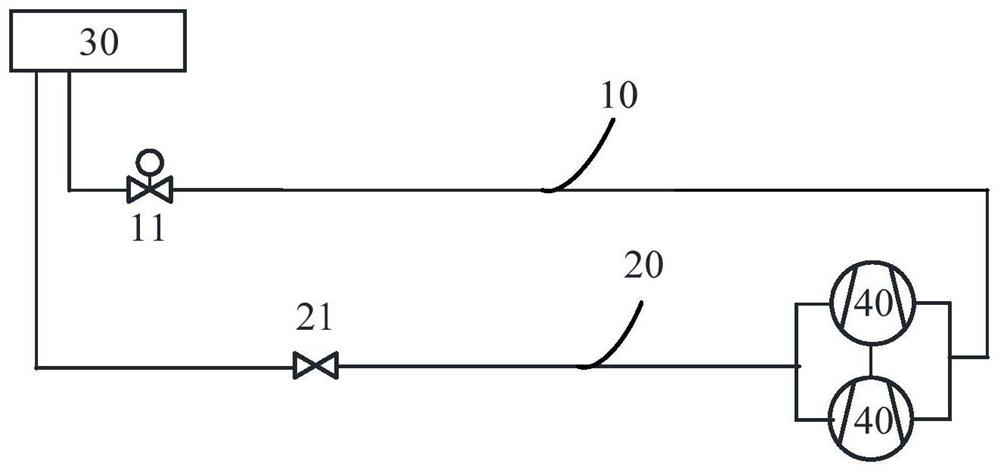

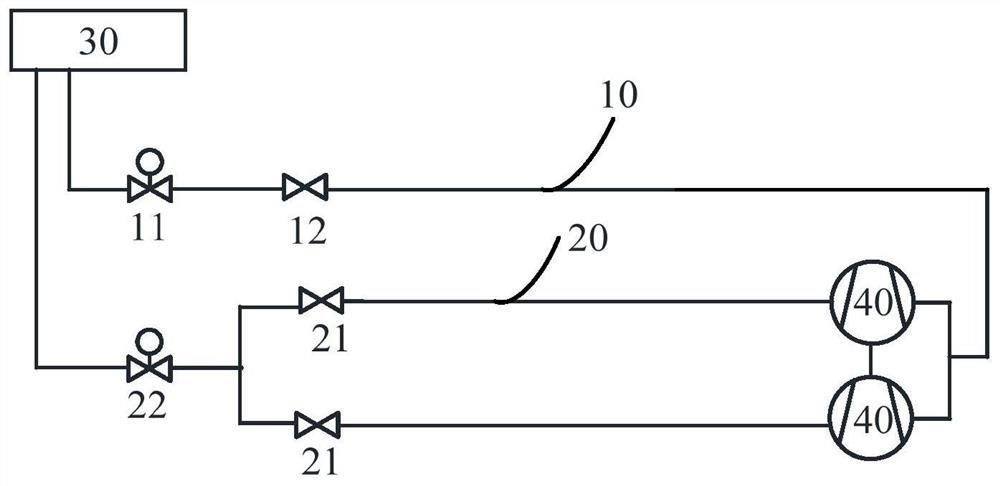

[0047] figure 1 It is a schematic structural diagram of the motor cooling device provided by Embodiment 1 of the present invention, as shown in figure 1 As shown, the motor cooling device includes:

[0048] The first cooling pipeline 10 is connected between the liquid intake end 30 and the motor cavity of the compressor 40. The first cooling pipeline 10 is provided with a first valve 11, and the opening of the first valve 11 is controlled according to the user's operation;

[0049] The second cooling pipeline 20 is connected between the liquid intake end 30 and the motor chamber of the compressor 40. The second cooling pipeline 20 is provided with a second valve 21, and the opening of the second valve 21 is automatically adjusted according to the load of the unit. control.

[0050] ...

Embodiment 2

[0062] This embodiment provides a motor cooling control method, which is implemented based on the motor cooling device described in the above embodiments.

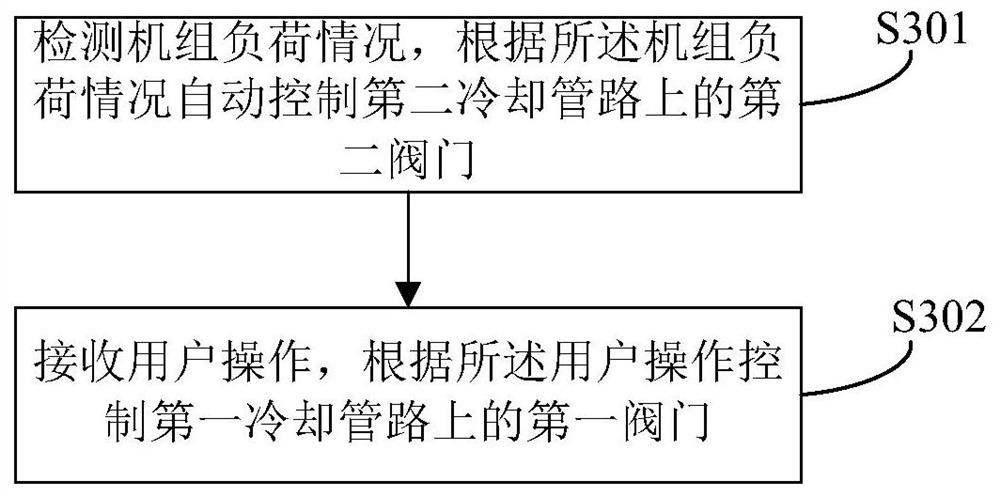

[0063] image 3 It is a flow chart of the motor cooling control method provided by Embodiment 2 of the present invention, such as image 3 As shown, the method includes the following steps:

[0064] S301. Detect the load condition of the unit, and automatically control the second valve on the second cooling pipeline according to the load condition of the unit.

[0065] S302. Receive a user operation, and control the first valve on the first cooling pipeline according to the user operation.

[0066] Wherein, the load condition of the unit refers to the current load of the unit, which can be represented by a unit load rate, for example. User operation refers to the user's operation to control the first valve. It may be that the user directly adjusts the first valve by hand, or the user inputs a control command for the fir...

Embodiment 3

[0080] This embodiment gives a specific example to illustrate the above-mentioned motor cooling device and motor cooling control method. However, it should be noted that this specific example is only for better illustrating the present application and does not constitute an improper limitation of the present application. . Explanations of terms that are the same as or corresponding to those in the foregoing embodiments will not be repeated in this embodiment.

[0081] In this embodiment, the unit includes two compressors connected in series, and liquid is taken from the condenser to cool the motor as an example.

[0082] like Figure 4 As shown, the unit includes: a compressor 1 and a compressor 2 connected in series, a condenser 3 , a filter 4 , a throttling device 5 and an evaporator 6 . One end of the first cooling pipeline (that is, the manual cooling adjustment pipeline) is connected to the bottom of the condenser shell tube or the condenser liquid collection bag, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com