Horizontal high back pressure centrifugal pump set

A high back pressure, centrifugal pump technology, applied in the field of hydraulic machinery, horizontal single-stage single-suction centrifugal pump, can solve the problems of lack of anti-pressure structure of centrifugal pump, deterioration of bearing working environment, pump can not operate normally, etc., to achieve effective sealing Guarantee, simple structure, and the effect of improving the quality of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

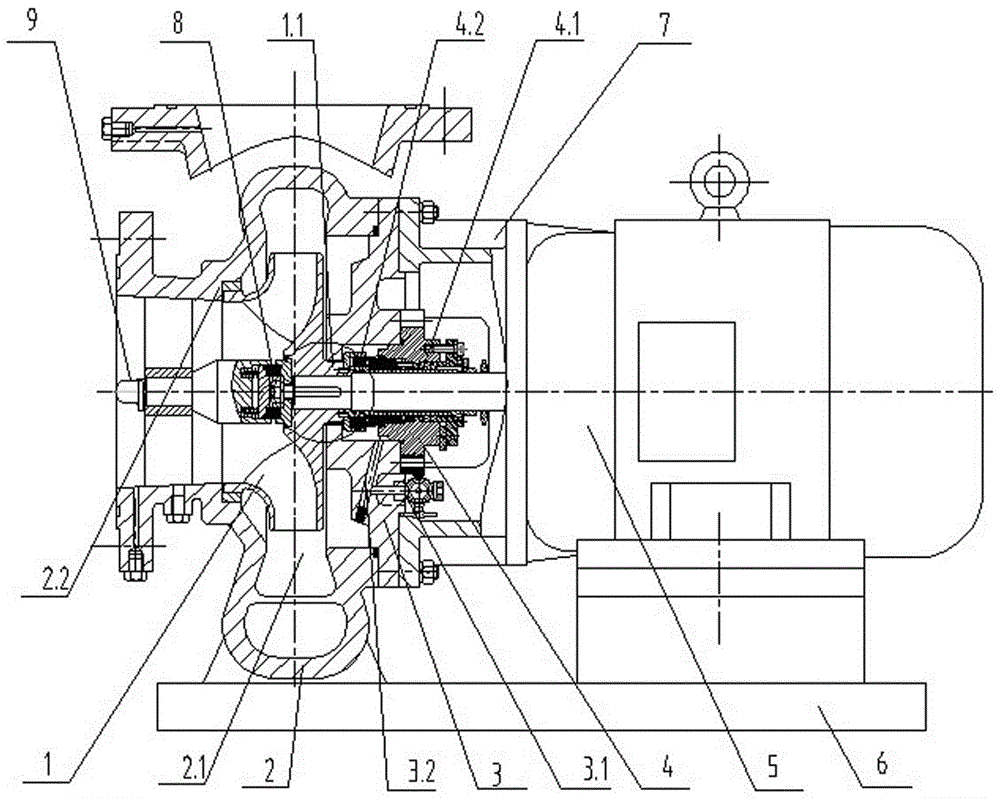

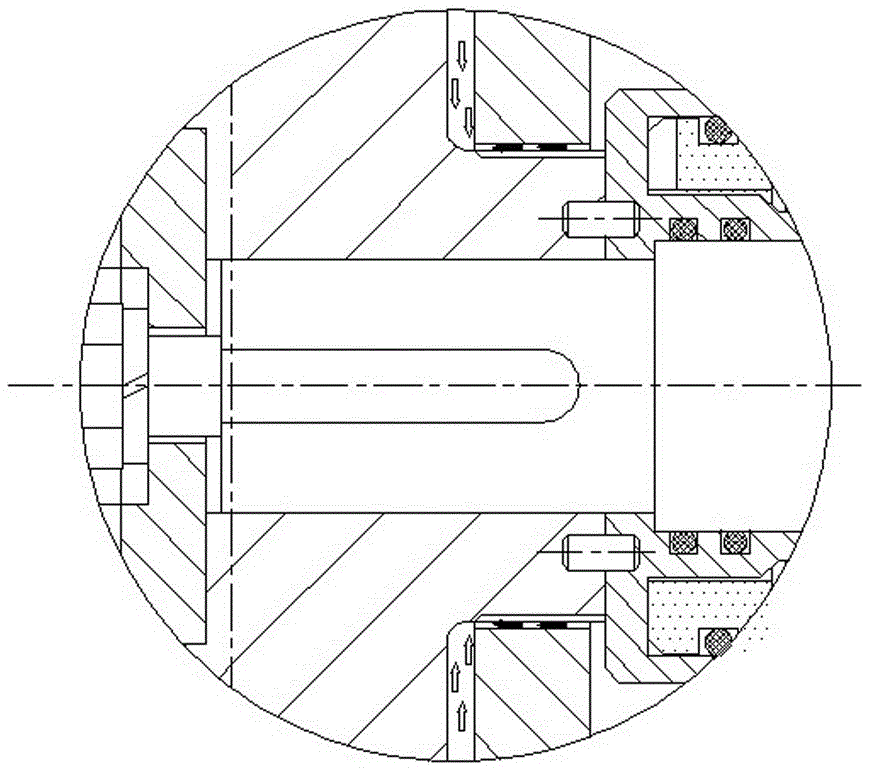

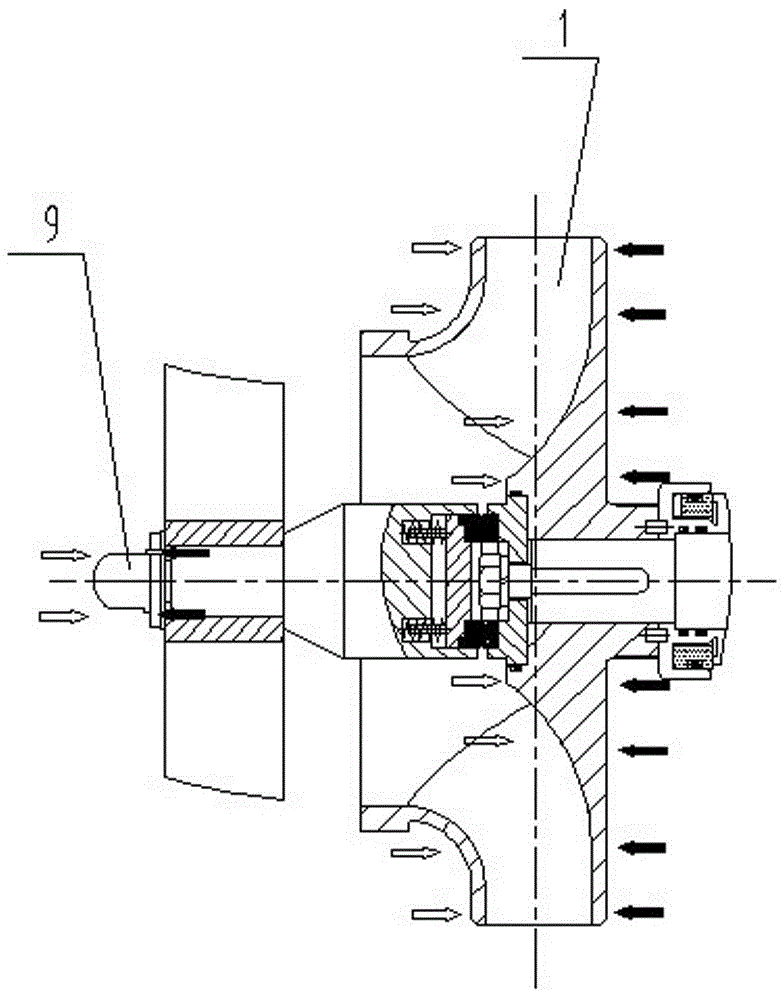

[0022] figure 1 The horizontal high back pressure centrifugal pump unit shown includes an impeller 1, a pump body 2, a pump cover 3, a seal seat 4, a motor 5, a base 6, a bracket 7, an elastic shaft top 8 and a nut 9. The base 6 is a flat base part, and the pump body 2 and the motor 5 are coaxially installed on the base 6 at the bottom. The pump body 2 used is a horizontal casing, the built-in flow channel 2.1 is a double-layer volute structure, and the layer partitions of the flow channel 2.1 form a rib-shaped strengthening structure. The pump body 2 is a rear window structure, the impeller 1 is loaded into the built-in flow channel of the pump body 2 from the right side, and the pump cover 3 blocks the right end surface of the pump body 2 . The left end surface of the pump cover 3 is provided with an inner hole in the center, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com