Drying, deodorizing and cooling device for plastic

A cooling device and drying technology, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of long cooling time for cooling liquid, restricting the development of enterprises, and long drying time, so as to reduce the drying time , speed up the drying process, speed up the effect of drying and cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

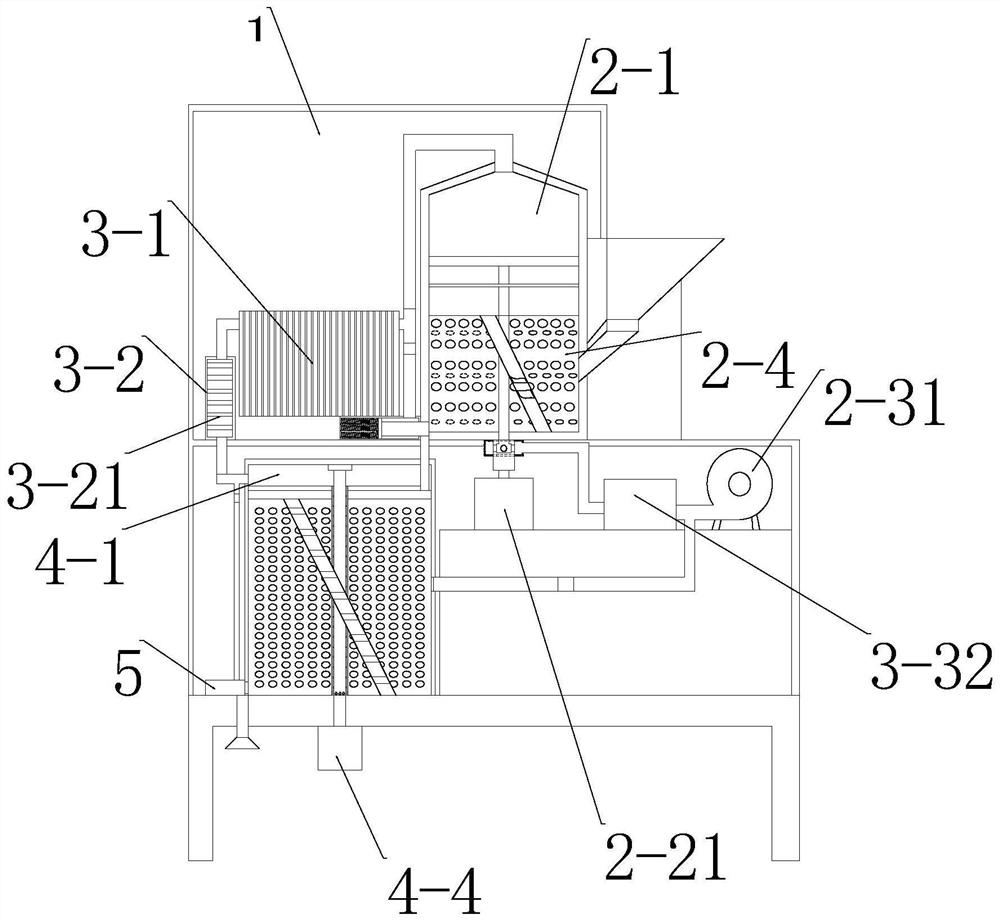

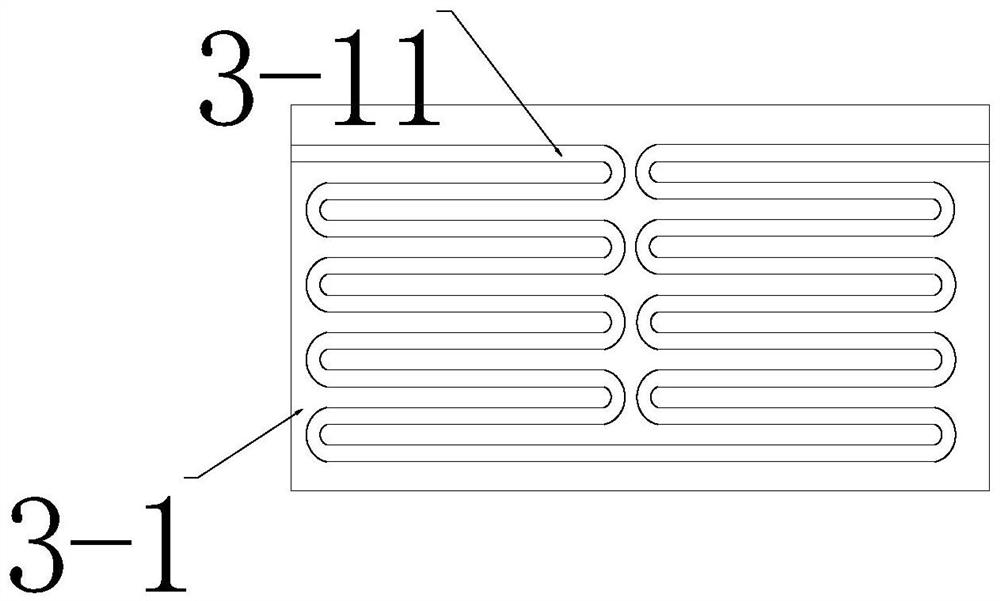

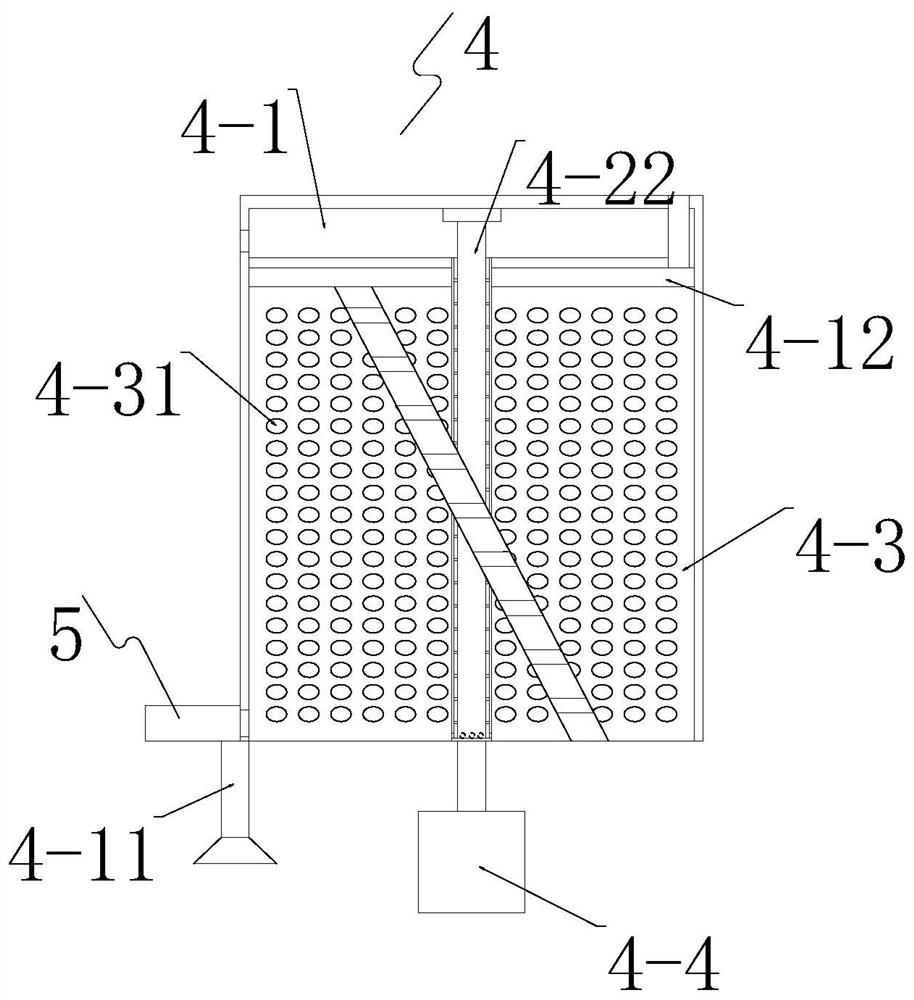

[0027] Example: such as Figure 1-9 As shown, a drying and deodorizing cooling device for plastics, the drying and deodorizing cooling device includes a bracket 1, a drying mechanism 2, a deodorizing heat dissipation mechanism 3, and a cooling mechanism 4, and the drying mechanism 2 is installed on the bracket 1 from top to bottom. 1. Cooling mechanism 4, deodorizing heat dissipation mechanism 3 and drying mechanism 2 are installed on the bracket 1 from left to right. Deodorize and dissipate heat from the high-temperature water vapor generated by the drying mechanism 2, and provide cooling air for the cooling mechanism 4. The cooling mechanism 4 makes the plastic pellets drop from a high place and cools and air-dries the plastic pellets.

[0028] The model of all motors involved in this device is JSF 42-3-30-AS-1000, and all motors, electric control valves, air machines 2-31, heaters 2-32 and humidity sensors involved in this device Both are connected with the external contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com