3D printing device and method for repairing faults of circuit board

A 3D printing and 3D printer technology, applied in the field of 3D printing, can solve the problems of high difficulty and low efficiency when repairing circuit boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

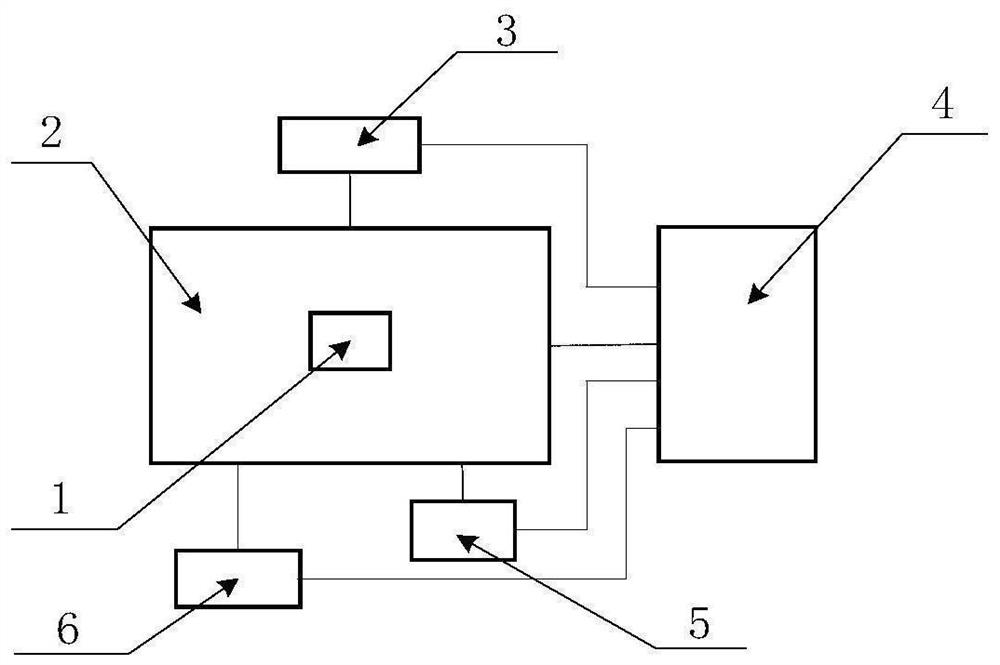

[0019] A kind of 3D printing device that is used to repair circuit board failure, comprises micro-jet 3D printer 2, and described micro-jet 3D printer 2 is installed with industrial camera 3, four-probe measuring instrument 6 above its workbench, industrial camera 3 and The micro-jet 3D printer 2 is electrically connected to the controller 4 through wires; the micro-jet 3D printer 2 is provided with an infrared laser 5 that moves with the printer nozzle on the working arm where the printer nozzle is installed; wherein the controller 4 Realize the control of the working path of the infrared laser 5 by controlling the working arm of the micro-jet 3D printer 2 while realizing the micro-jet 3D printer 2 injection path and the injection volume; the controller 4 is also used to receive pictures taken by the industrial camera 3 information and carry out the identification of the photographed content in order to detect the fault area; the industrial camera 3 is used to photograph the c...

Embodiment 2

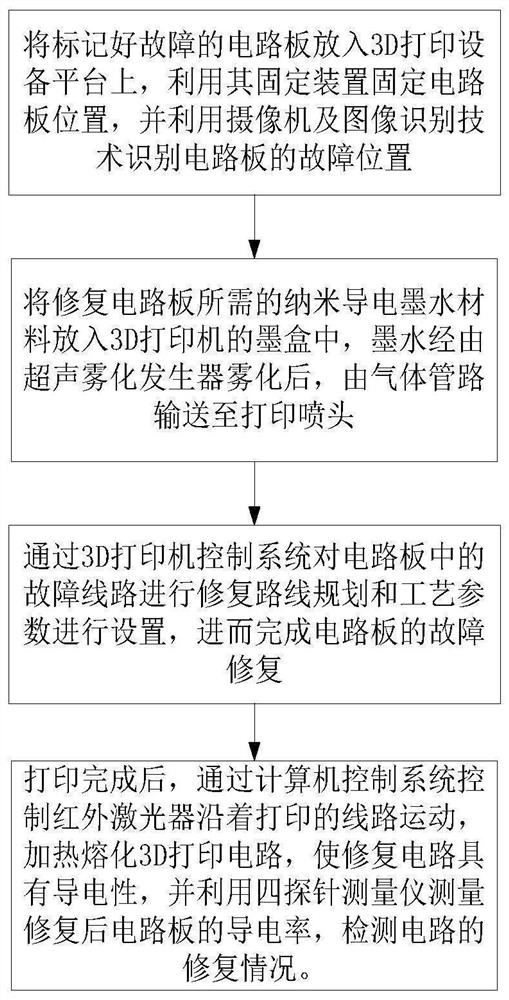

[0021] A method for utilizing the 3D printing device described in embodiment 1 for repairing circuit board faults, wherein the method comprises the following steps: 1), the circuit board 1 marking the fault position is placed on the work of the micro-jet 3D printer 2 on the platform, and use the fixing device on the working platform to fix the circuit board 1, the controller 4 takes pictures of the circuit board 1 through the industrial camera 3, and uses image recognition technology to identify the fault location of the circuit board 1;

[0022] 2) Put the nano-conductive ink material required for repairing the circuit board 1 into the ink cartridge of the micro-jet 3D printer 2. After the nano-conductive ink material is atomized by the ultrasonic atomization generator, it is transported to the micro-jet 3D printer by the gas pipeline 2 print heads;

[0023] 3), carry out the planning of repairing circuit to the circuit fault in circuit board 1 by controller 4, and set proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com