Smelting furnace waste heat recovery device for glass production and using method thereof

A waste heat recovery device and glass melting furnace technology, applied in glass production, glass furnace equipment, glass manufacturing equipment, etc., can solve the problems of energy waste, environmental pollution, and energy can not be fully utilized, etc., to achieve good practicability and ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

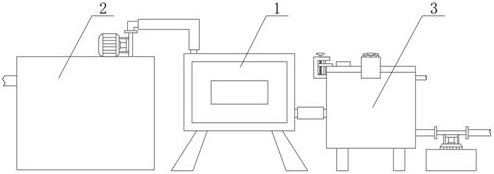

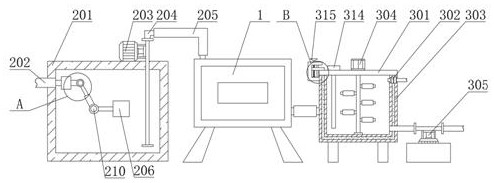

[0024] see Figure 1-5 , the present invention provides a technical solution:

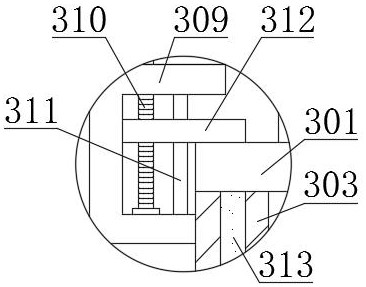

[0025] A furnace waste heat recovery device for glass production, comprising a glass melting furnace 1, the glass melting furnace 1 is also connected with a cooling water supply mechanism 2 and a hot water supply mechanism 3, the hot water supply mechanism 3 includes a water storage tank 303 and a second water pump 305, the storage The left end of the water tank 303 communicates with the glass melting furnace 1, and the inner side of the water tank 303 is fixedly connected with an insulating layer 313. The input end of the top cover 301 is fixedly connected with a temperature sensor 314 and a motor 304, the sensing end of the temperature sensor 314 is arranged on the inner side of the water storage tank 303, the end of the main shaft of the motor 304 is fixedly connected with a rotating rod 306, and the rotating rod The outer side of 306 is fixedly connected with stirring rod 307, the outer side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com