UV silicon touch matte coating and preparation method and application thereof

A silicon feel, matte technology, used in the field of interior coatings, can solve the problems of hard PU rubber paints that are not smooth enough, poor feel comfort, and sticking back after the coating use time, and achieve good wear resistance and low gloss. , the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

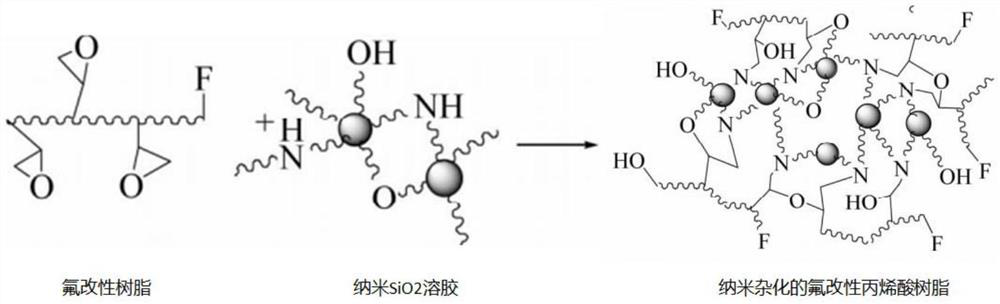

Method used

Image

Examples

preparation example Construction

[0033] According to another aspect of the present invention, there is also provided a preparation method comprising the above-mentioned UV silicon feel matte paint, comprising the following steps:

[0034] The preparation method of component A includes: mixing photoinitiator, hand feeling aid agent, wetting and dispersing agent and organic solvent, stirring until fully dissolved, then adding UV self-extinction acrylate, UV organofluorosilicon modified acrylate, Specially modified acrylate and mercapto compound, stir, stirring time is 5min~10min, stirring speed is 600r / min~800r / min, then add titanium dioxide matting powder, silicone powder and PTFE wax powder while stirring, stir The time is 20min~25min, the stirring speed is 1800rpm~2400rpm / min, filter to obtain A component;

[0035] The preparation method of component B includes: stirring component B, the stirring time is 5 min to 10 min, the stirring speed is 500 rpm to 800 rpm / min, and filtering to obtain component B;

[0...

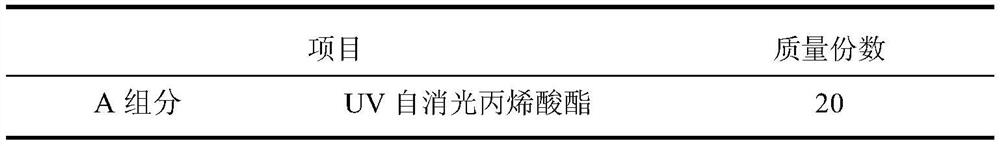

Embodiment 1

[0055] UV Silicone Touch Matte Coatings, including in parts by weight:

[0056] Table 1 Adding amount of UV silicon touch matte paint

[0057]

[0058]

[0059] The preparation method of above-mentioned UV silicon feel matte paint, comprises the following steps:

[0060] The preparation method of component A includes: mixing photoinitiator, hand feeling aid, wetting and dispersing agent and organic solvent, stirring until fully dissolved, then adding UV self-extinguishing acrylate, UV organofluorosilicon modified acrylate, special Modified acrylate and sulfhydryl compound, stirred for 10 minutes and stirring speed of 700 rpm, and then added titanium dioxide matting powder, silicone powder and PTFE wax powder while stirring, stirring time was 20 minutes, stirring speed was 2000 rpm rev / min, filter with a 200-mesh filter screen to obtain component A;

[0061]The preparation method of component B includes: stirring component B, the stirring time is 10 minutes, the stirrin...

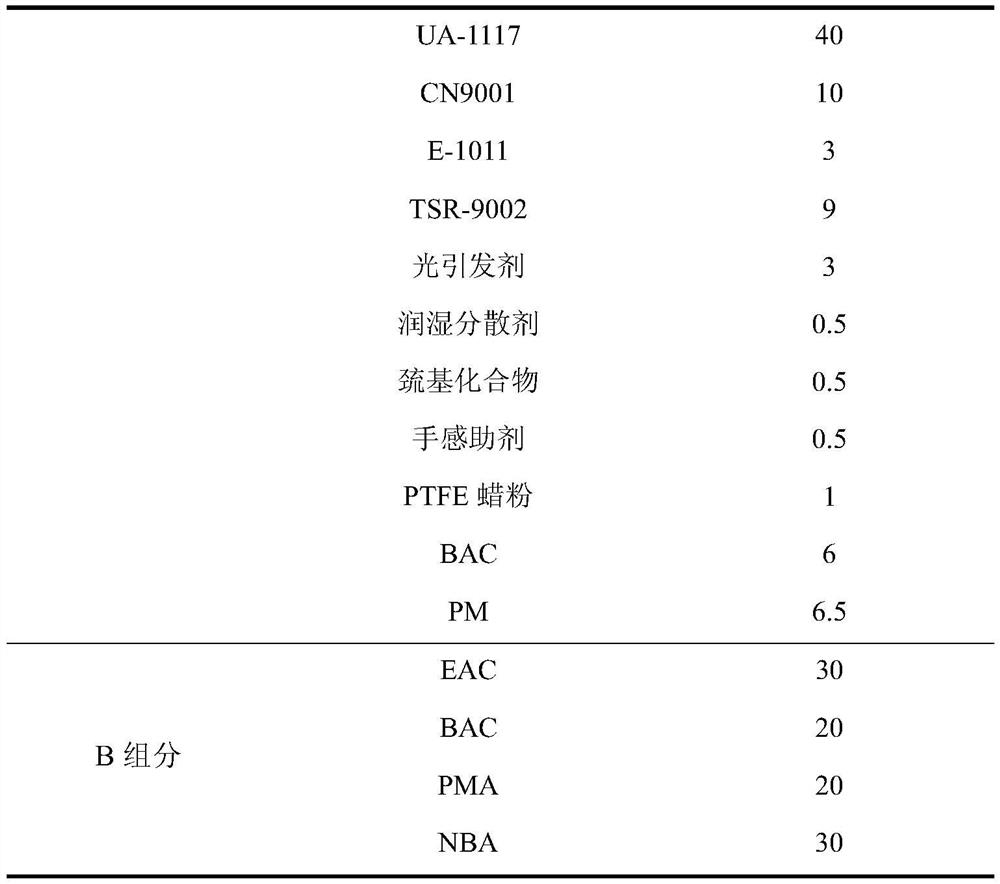

Embodiment 2

[0064] UV Silicone Touch Matte Coatings, including in parts by weight:

[0065] Table 2 Adding amount of UV silicon touch matte paint

[0066]

[0067]

[0068] The preparation method of the above-mentioned UV silicon touch matte coating is similar to that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com