Preparation method of high-strength Ti-ZrO2-B4C system composite material

A technology of ti-zro2-b4c and composite materials, which is applied in the field of preparation of high-strength Ti-ZrO2-B4C system composite materials, can solve the problems of low strength and cannot meet the requirements of use, etc., and achieves excellent performance, hardness and compressive strength. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

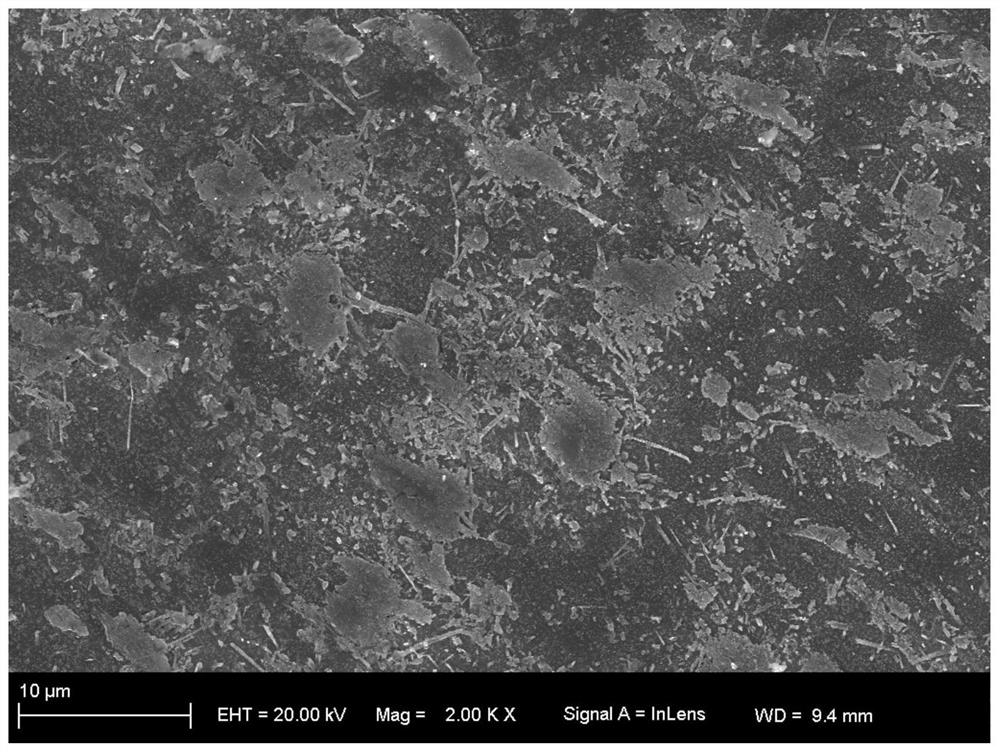

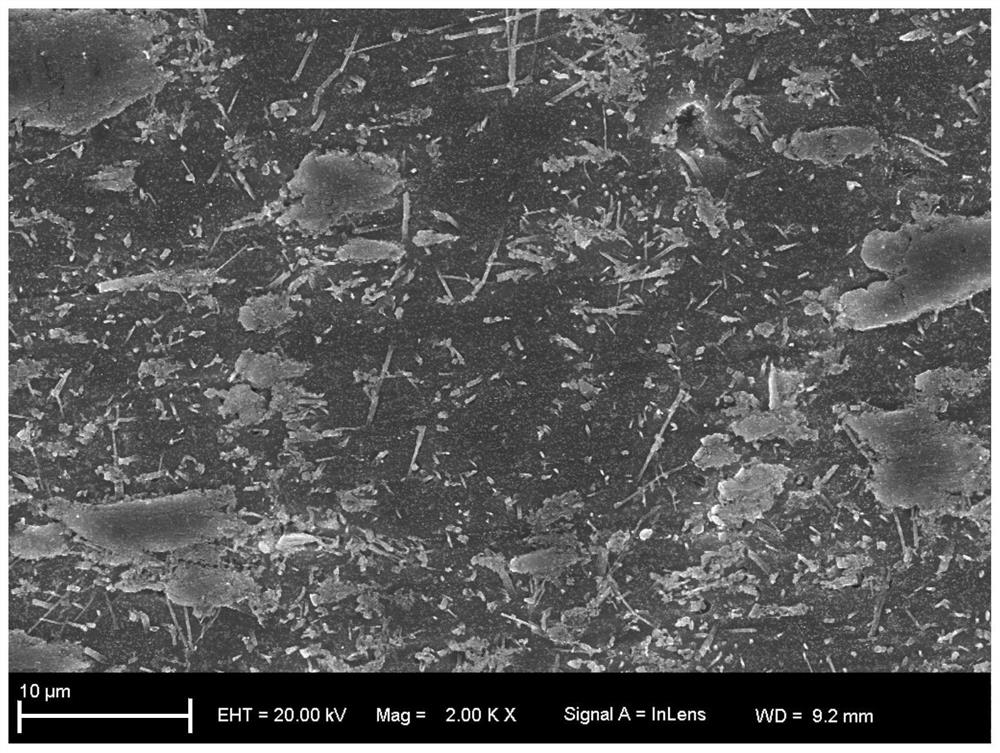

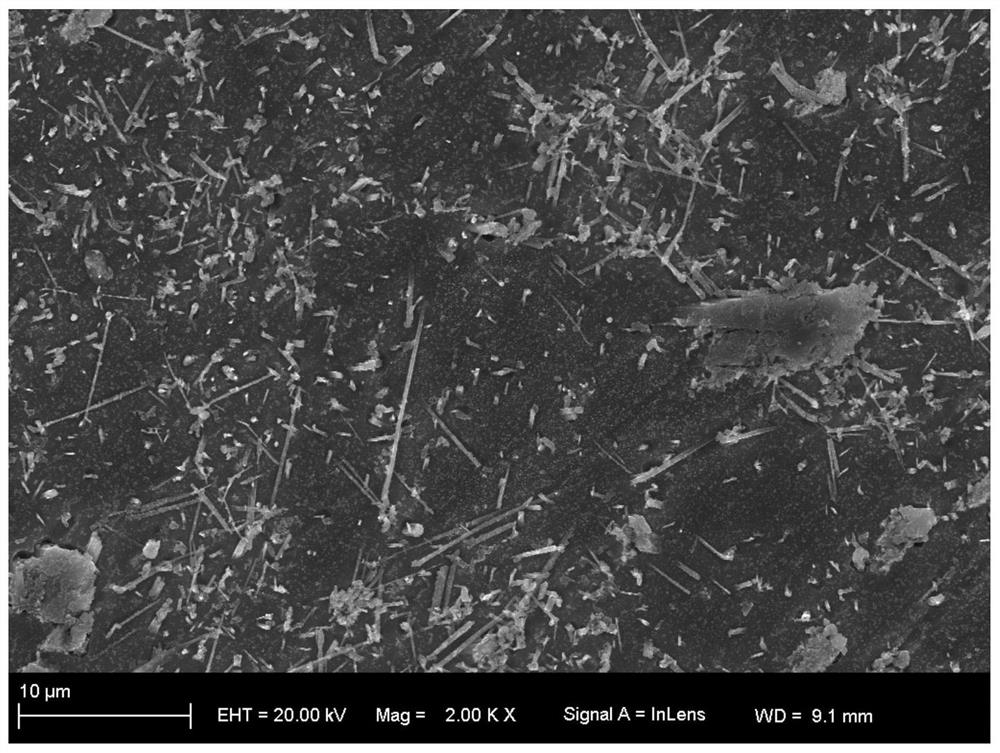

Image

Examples

preparation example Construction

[0028] The invention provides a high-strength Ti-ZrO 2 -B 4 The preparation method of C system composite material specifically comprises the following steps:

[0029] Step 1, mix the powder

[0030] According to the mass fraction of 0.1%-1.1% in Ti-B 4 C powder is added with the third component ZrO 2 powder, where B 4 C powder mass accounts for 1.1%-2.8% of the total powder mass, pure Ti powder particle size is 20-30μm, B 4 C powder particle size is 0.5-1.0μm, ZrO 2 The powder particle size is 1-3μm. Weigh the required powder and the zirconia balls used for powder mixing. The ratio of balls to materials is 1-3:1, the ratio of large balls to small balls is 3-4:1, the diameter of large balls is 9-11mm, and the diameter of small balls is 9-11mm. The diameter is 5-6mm; the three-dimensional vibrating powder mixer is used for powder mixing, and the frequency of the three-dimensional vibrating powder mixer is 30-60Hz. First, pure Ti powder and B 4 Add 0.04%-0.12% mass fracti...

Embodiment 1

[0038] The invention provides a high-strength Ti-ZrO 2 -B4 The preparation method of C system composite material specifically comprises the following steps:

[0039] Step 1, mix the powder

[0040] Prepare the required raw powder, pure Ti powder with a particle size of 20 μm, and B with a particle size of 0.5 μm 4 C powder, ZrO with a particle size of 1 μm 2 powder; respectively weigh 49.52g of pure Ti powder, B 4 C powder 0.81g, ZrO 2 0.11g of powder and the zirconia balls to be used, put the weighed powder and zirconia balls aside; the ratio of balls to materials is 2:1, the ratio of large balls to small balls is 4:1, and the diameter of large balls is 9-11mm , the diameter of the ball is 5-6mm; the three-dimensional vibrating powder mixer is used for powder mixing, and the frequency of the three-dimensional vibrating powder mixer is 50Hz. First, pure Ti powder and B 4 Add 0.08% mass fraction of vacuum pump oil to C powder, mix the powder for 1 hour, and then add ZrO pr...

Embodiment 2

[0049] The invention provides a high-strength Ti-ZrO 2 -B 4 The preparation method of C system composite material specifically comprises the following steps:

[0050] Step 1, mix the powder

[0051] Prepare the required raw powder, pure Ti powder with a particle size of 20 μm, and B with a particle size of 0.5 μm 4 C powder, ZrO with a particle size of 1 μm 2 Powder; respectively weigh 49.33g of pure Ti powder, B 4 C powder 0.81g, ZrO 2 0.30g of powder and the zirconia balls to be used, put the weighed powder and zirconia balls aside; the ratio of balls to materials is 2:1, the ratio of large balls to small balls is 4:1, and the diameter of large balls is 9-11mm , the diameter of the ball is 5-6mm; the three-dimensional vibrating powder mixer is used for powder mixing, and the frequency of the three-dimensional vibrating powder mixer is 50Hz. First, pure Ti powder and B 4 Add 0.08% mass fraction of vacuum pump oil to C powder, mix the powder for 1 hour, and then add ZrO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com