Dust removal device for textile cloth

A dust removal device and dust brushing technology, which is applied in the direction of combined devices, textile and papermaking, and separation of dispersed particles, can solve the problems of polluting the delivery room environment and endangering the health of operators, so as to improve the environment, avoid dust floating, and ensure health. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

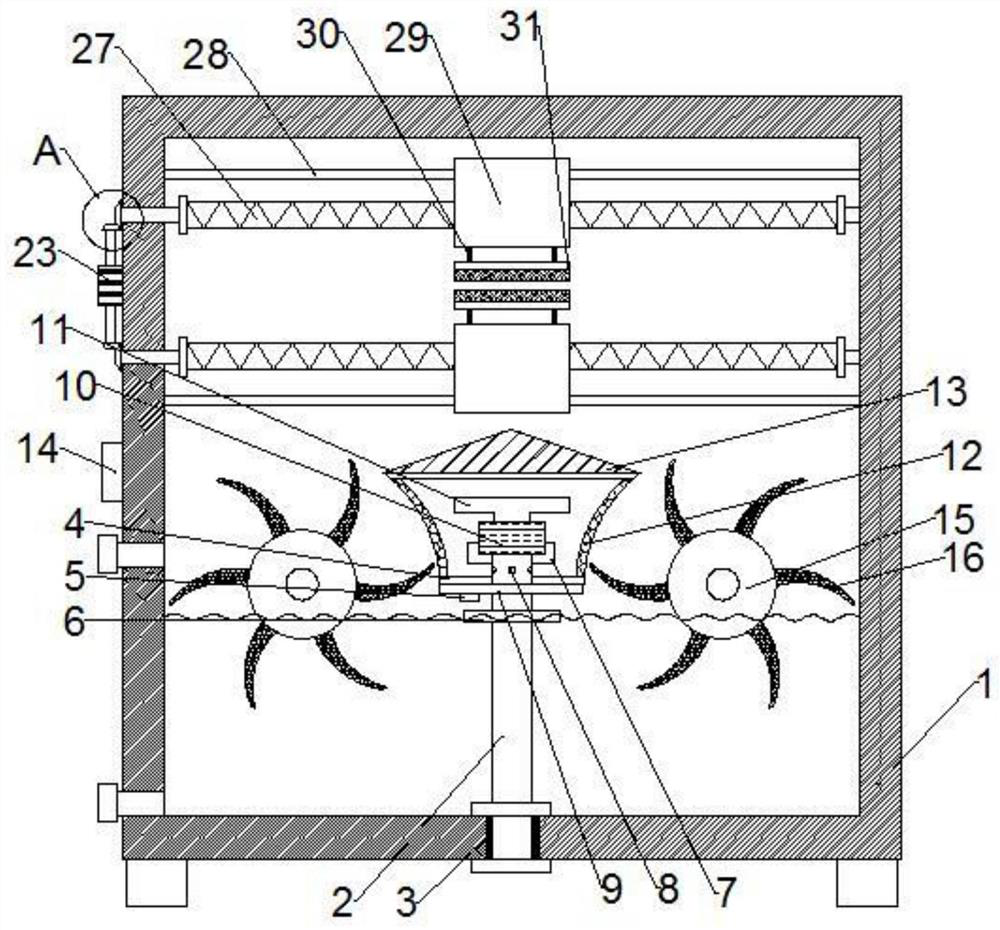

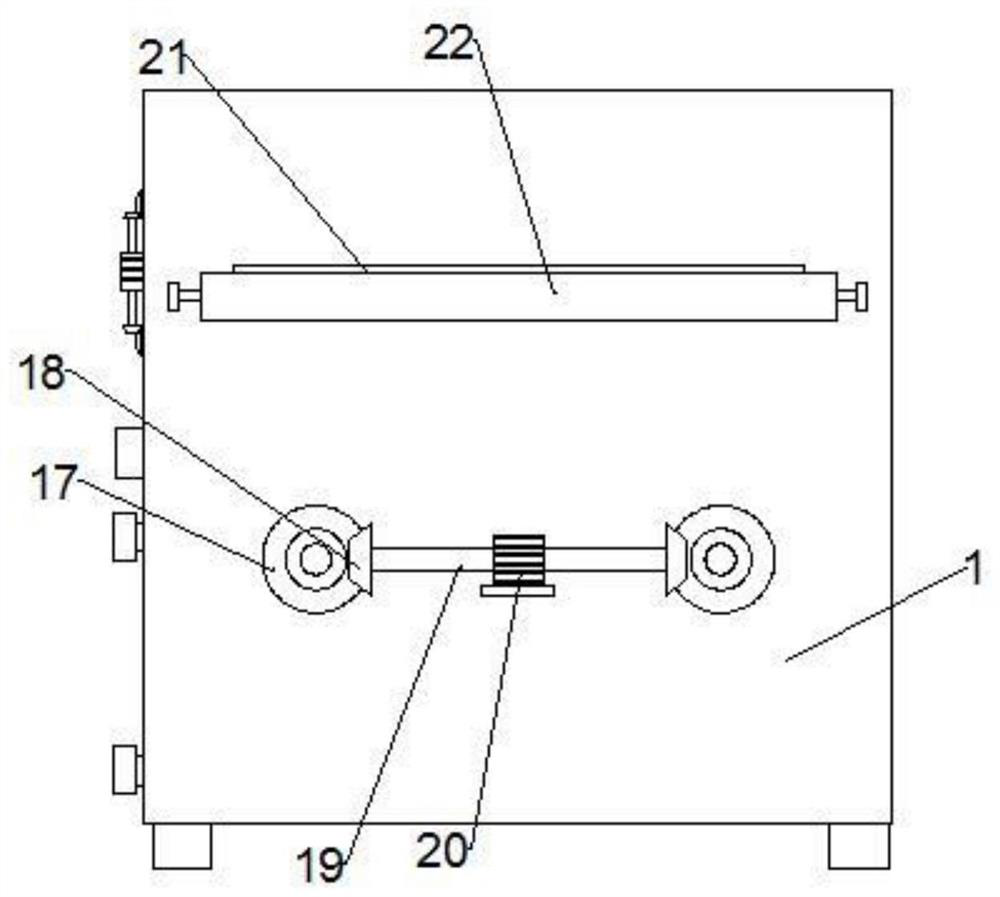

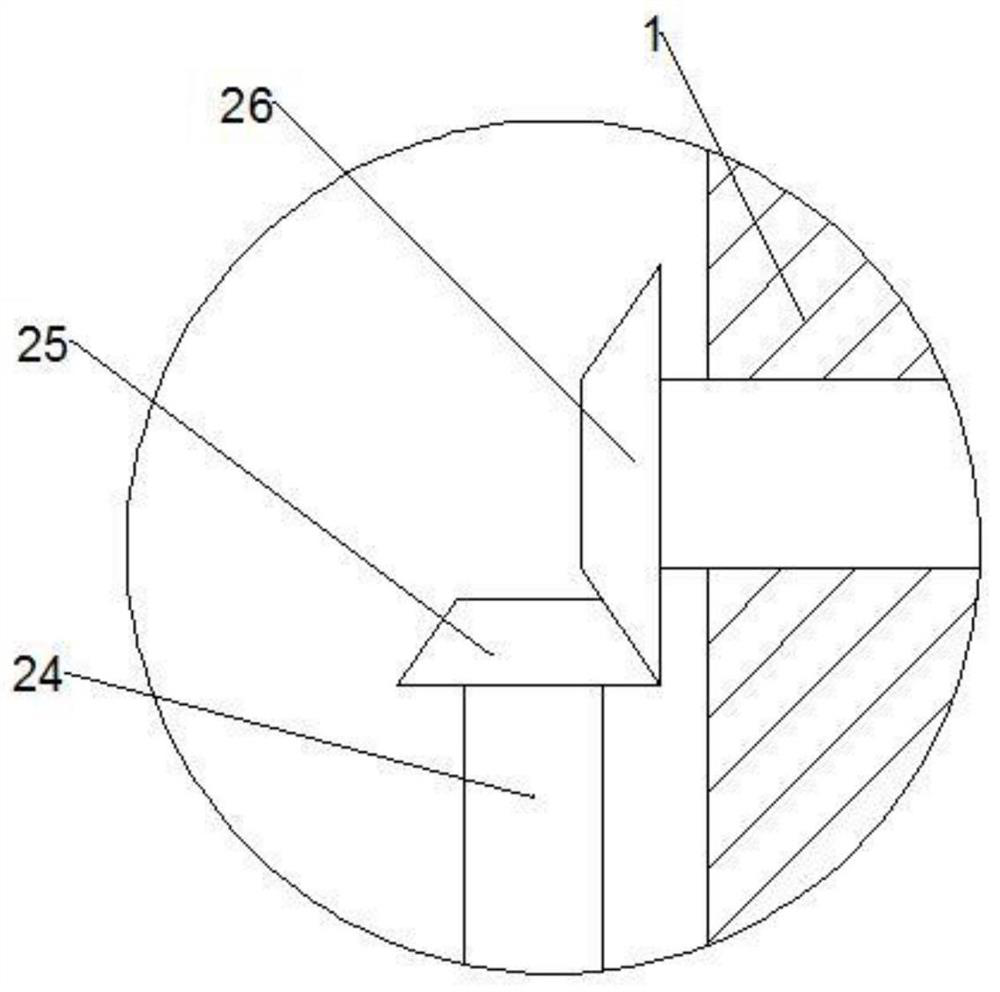

[0019] see Figure 1-3 , a dust removal device for textile cloth, comprising a main body 1, through holes 21 are respectively provided on the front and rear shell walls of the main body 1, and a dust brushing mechanism and a dust stopping mechanism are arranged on the inner side of the main body 1, and the The dust brushing mechanism is located on the upper side of the dust-removing mechanism, and the dust-removing mechanism includes a drum 15. The bottom side of the main body 1 is provided with a water storage chamber, and a water level alarm mechanism is provided in the water storage chamber. The main body 1 The bottom side of the hollow pillar 2 is fixedly interspersed with a hollow pillar 2, the bottom end of the hollow pillar 2 passes through the bottom side shell wall of the main body 1, and the upper end of the hollow pillar 2 is fixedly inserted in the support box 4, and the support box 4 is located at the upper end of the support plate 9, and the support plate 9 is fi...

Embodiment 2

[0027] see Figure 1-3, this embodiment is further optimized on the basis of Embodiment 1. Specifically, the water level alarm mechanism includes an inductor 5, and a sliding sleeve 6 is provided on the hollow pillar 2 inserted in the main body 1, so The bottom end of the support plate 9 is fixedly provided with an inductor 5, the outside of the main body 1 is provided with an alarm 14, and the sliding sleeve 6 can slide on the hollow pillar 2, and the sliding sleeve 6 is placed in the water. Moving upwards under the action of buoyancy, when the sliding sleeve 6 is in contact with the sensor 5, the alarm 14 will be triggered to alarm, thereby avoiding too much water in the main body 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap