Fiber bragg grating sensor intelligent cable for building cable structure

A fiber grating and sensor technology, applied in building components, building structures, buildings, etc., can solve problems such as affecting the appearance of buildings, inability to obtain results directly, and being susceptible to external interference, and achieve the effect of rapid cable force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the present invention, the following will clearly and completely describe the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only a part of the present invention, rather than Full examples.

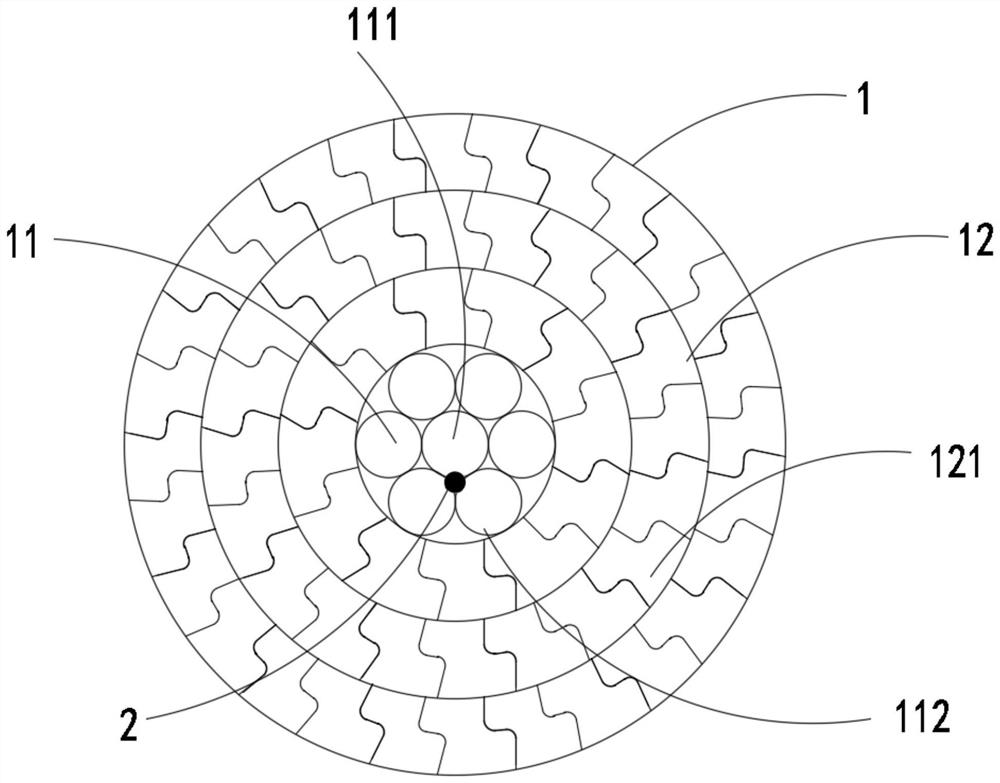

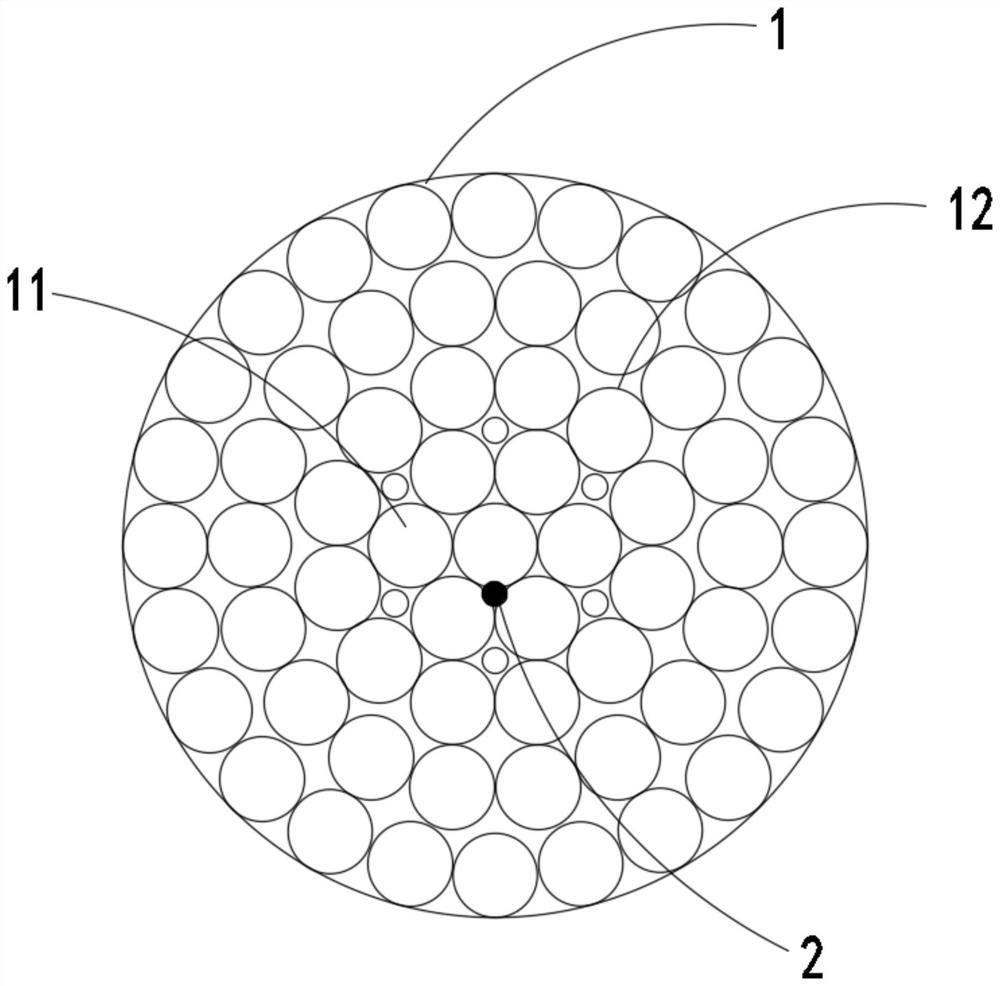

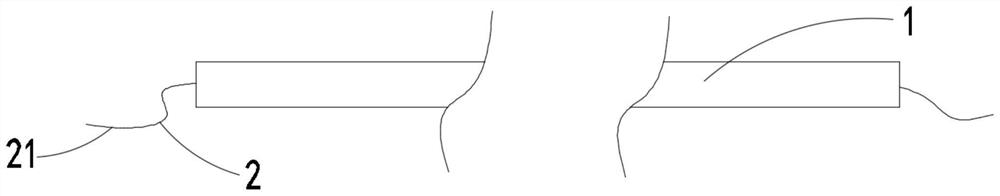

[0020] The embodiment of the present invention discloses a fiber grating sensor smart cable for building cable structure, such as figure 1 , figure 2 As shown, it includes a cable body 1 and an optical fiber grating sensor 2. The cable body 1 is composed of several steel wires. The optical fiber grating sensor 2 is fixed in the cable body 1. The encapsulation structure is a fiber composite bar.

[0021] Optionally, the fiber composite rib is a fiber reinforced plastic-fiber grating composite sensing rib.

[0022] Among them, such as figure 1 , figure 2 As shown, the fiber grating sensor smart cable according to the embodiment of the present invention im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| breaking force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com