An ultrasensitive gas sensor based on graphene D-shaped optical fiber

A gas sensor and graphene technology, which is applied in the field of sensing, can solve the problems of limiting the sensitivity of the sensor, and there is no improvement scheme for the sensitivity of the D-shaped optical fiber sensor, and achieve the effect of improving the sensing response capability, simple structure and small size of the device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawings and examples.

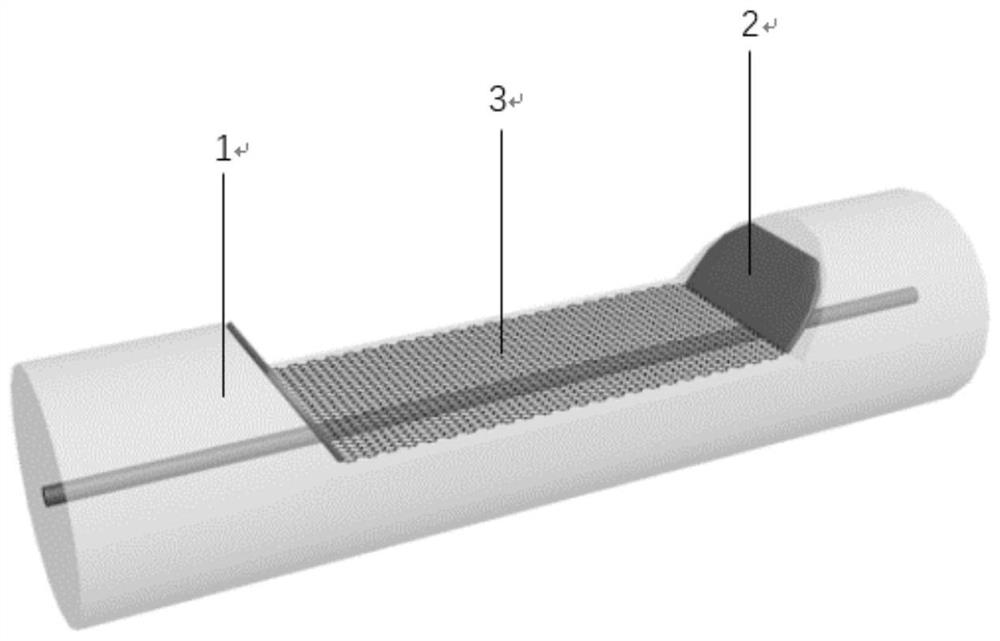

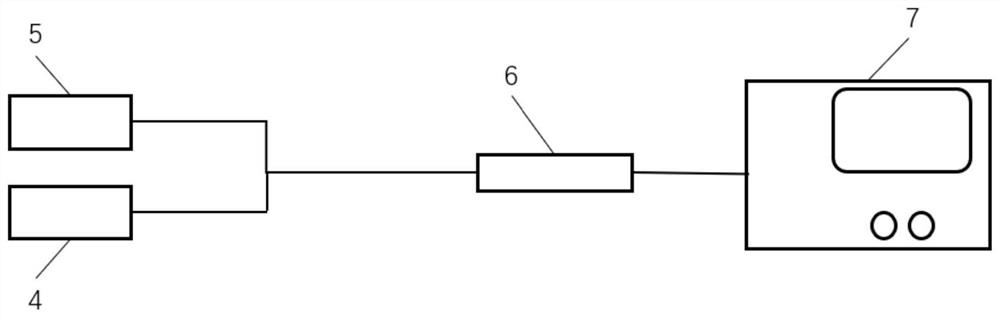

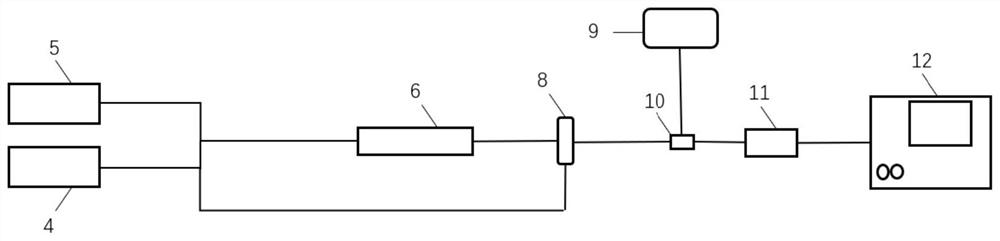

[0023] An ultrasensitive gas sensor based on a graphene D-shaped optical fiber, comprising a D-shaped optical fiber (1), a graphene film (3), and a gold-graphene-gold heterojunction structure. The D-shaped optical fiber (1) is formed by polishing a single-mode optical fiber with a core diameter of 8 microns. The graphene film (3) is attached to the polished surface of the D-shaped optical fiber, and the gold film (2) with a thickness of 50 nm is sprayed on the D-shaped optical fiber (1) by mask spraying method to form a complete gas sensing structure .

[0024] combine figure 1 , figure 2 As shown in the figure, select a part with a length of 5 cm and a core diameter of 8 microns on a single-mode optical fiber with a length of 1 meter to remove the coating layer, and polish the center of the fiber with the coating layer removed by side polishing . A D-sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com