Control method for ensuring air inlet flow precision

A technology of intake air flow and control method, which is applied in electrical control, engine control, fuel injection control, etc. It can solve the problems that it is difficult to ensure the accuracy of multiple sensors and the error of intake air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

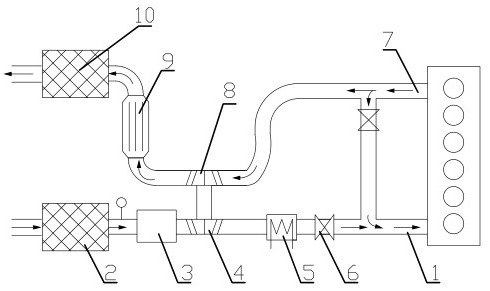

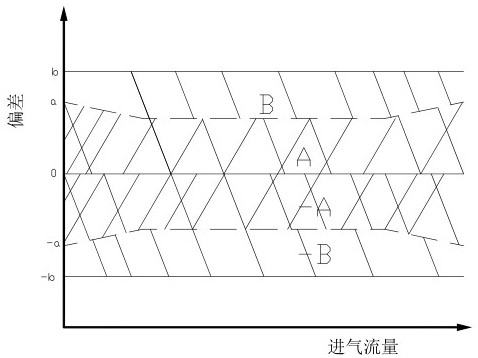

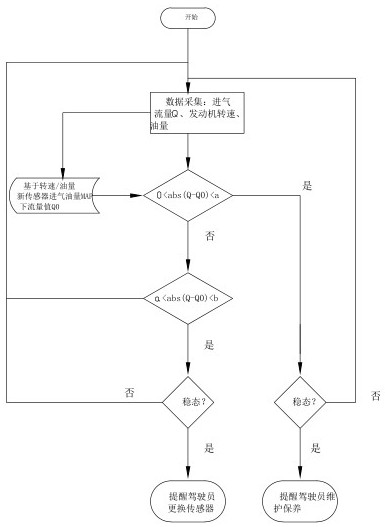

[0016] Figure 1 to Figure 3 As shown, since the basic structure of the engine is the prior art, its basic structure will not be described in detail here. According to the working principle of the engine and the prior art, those skilled in the art clearly know that the various components in this embodiment are installed in the engine The position above will not be described in detail here. The frame structure of the relevant parts of the engine is given in the drawings and the embodiments. The present invention provides a control method for ensuring the accuracy of the intake air flow, which includes an engine and an air filter 2, a flow sensor 3, a compressor 4, an intercooler 5, and a throttle valve sequentially connected to the cylinder intake pipeline 1 6. A turbine 8, an aftertreatment system 9 and a muffler 10 are sequentially connected to the cylinder exhaust pipe 7. The engine is an engine with an EGR system. A supercharger is installed between the turbine and the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com