Magnetic levitation centrifugal compressor fault testing device and testing method

A centrifugal compressor and fault testing technology, which is applied to mechanical equipment, non-variable pumps, machines/engines, etc., can solve the problems of failures of single compressors that cannot be detected in time, the accuracy and stability of internal bearings cannot be identified and judged, Problems such as the high failure rate of the compressor on-line, achieve the effect of automatic and rapid detection, increase the failure detection rate, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

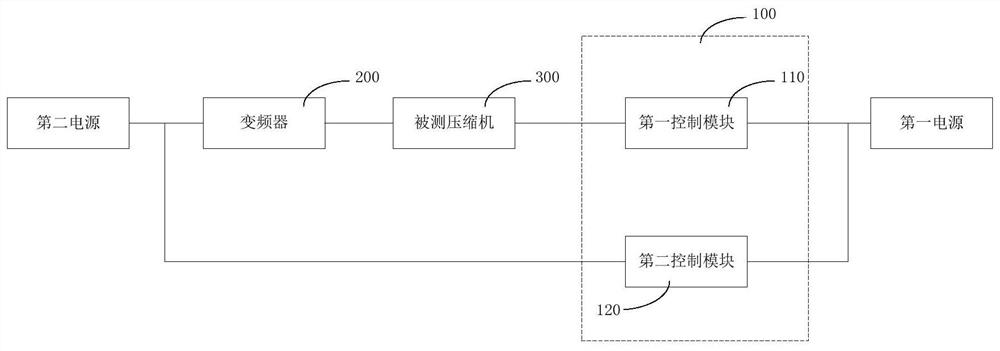

[0043] In this example, if figure 1 As shown, a magnetic levitation centrifugal compressor fault testing device is provided, including: a frequency converter 200 and a control module 100; It is used to connect with the bearing controller of the compressor under test, the second control terminal of the control module 100 is connected to the signal input terminal of the frequency converter 200, and the signal output terminal of the frequency converter 200 is used to communicate with the tested The measuring compressor is connected, and the power supply terminal of the frequency converter 200 is used for connecting with the second power supply.

[0044] Specifically, the frequency converter 200 is used to control the rotational speed of the motor of the compressor under test. Specifically, the frequency converter 200 changes the frequency and period of the AC power supply to the motor of the compressor under test, so as to control the speed of the compressor under test. The purp...

Embodiment 2

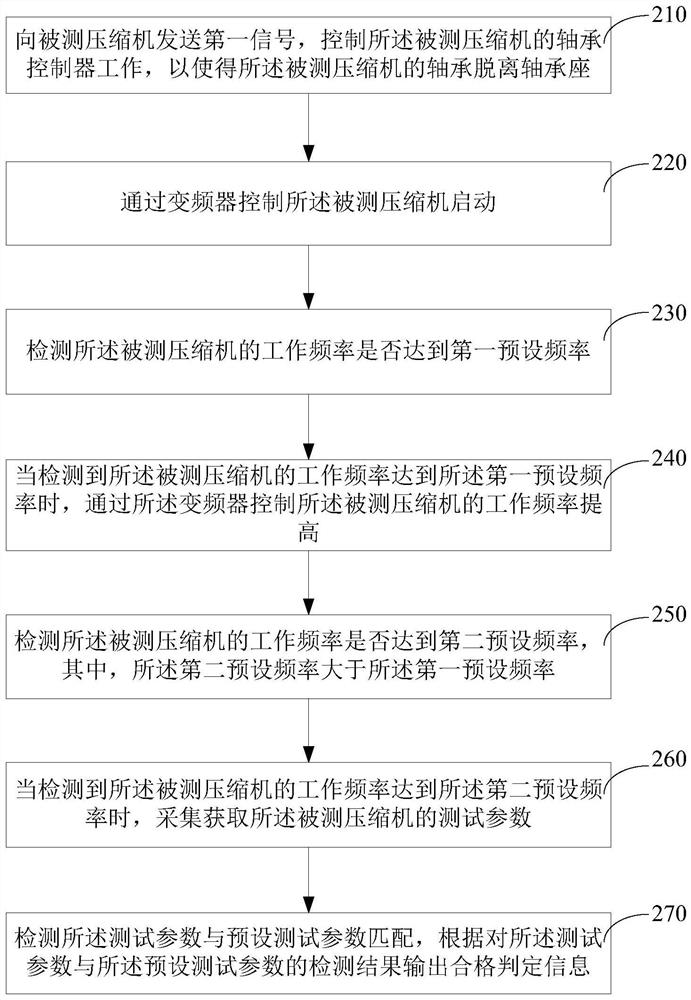

[0061] In this example, if figure 2 As shown, a magnetic levitation centrifugal compressor fault testing method is provided, including:

[0062] Step 210, sending a first signal to the compressor under test to control the bearing controller of the compressor under test to work, so that the bearing of the compressor under test breaks away from the bearing housing.

[0063] Step 220, controlling the compressor under test to start up through a frequency converter.

[0064] Step 230, detecting whether the operating frequency of the compressor under test reaches a first preset frequency.

[0065] Step 240, when it is detected that the operating frequency of the compressor under test reaches the first preset frequency, the frequency converter is used to control the operating frequency of the compressor under test to increase.

[0066] Step 250, detecting whether the operating frequency of the compressor under test reaches a second preset frequency, wherein the second preset frequ...

Embodiment 3

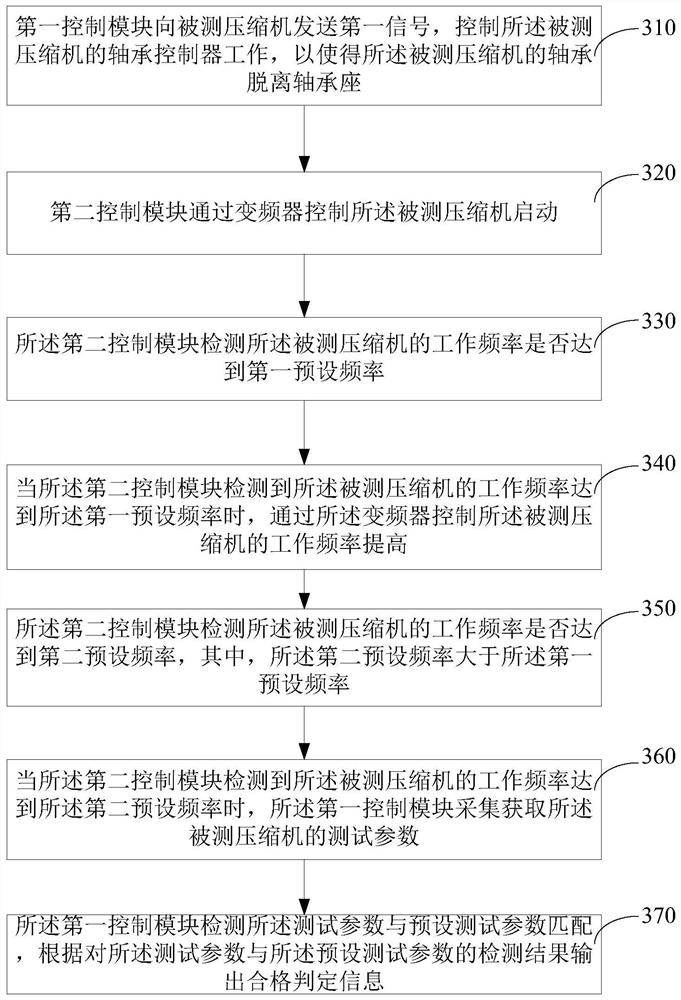

[0074] In this example, if image 3 As shown, a magnetic levitation centrifugal compressor fault testing method is provided, including:

[0075] Step 310, the first control module sends a first signal to the compressor under test to control the bearing controller of the compressor under test to work so that the bearing of the compressor under test breaks away from the bearing seat;

[0076] Step 320, the second control module controls the compressor under test to start through the frequency converter;

[0077] Step 330, the second control module detects whether the operating frequency of the compressor under test reaches a first preset frequency;

[0078] Step 340, when the second control module detects that the operating frequency of the compressor under test reaches the first preset frequency, control the operating frequency of the compressor under test to increase through the frequency converter;

[0079] Step 350, the second control module detects whether the operating fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com