Drying and dehumidifying device for rice processing

A technology of rice processing and drying mechanism, which is applied in the direction of drying, drying machine, drying gas arrangement, etc. It can solve the problems of secondary interference of rice, lack of cleaning and dehumidification function, and easy accumulation of impurities to affect the quality of rice, etc., to achieve improvement Purity, the effect of improving the convenience of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

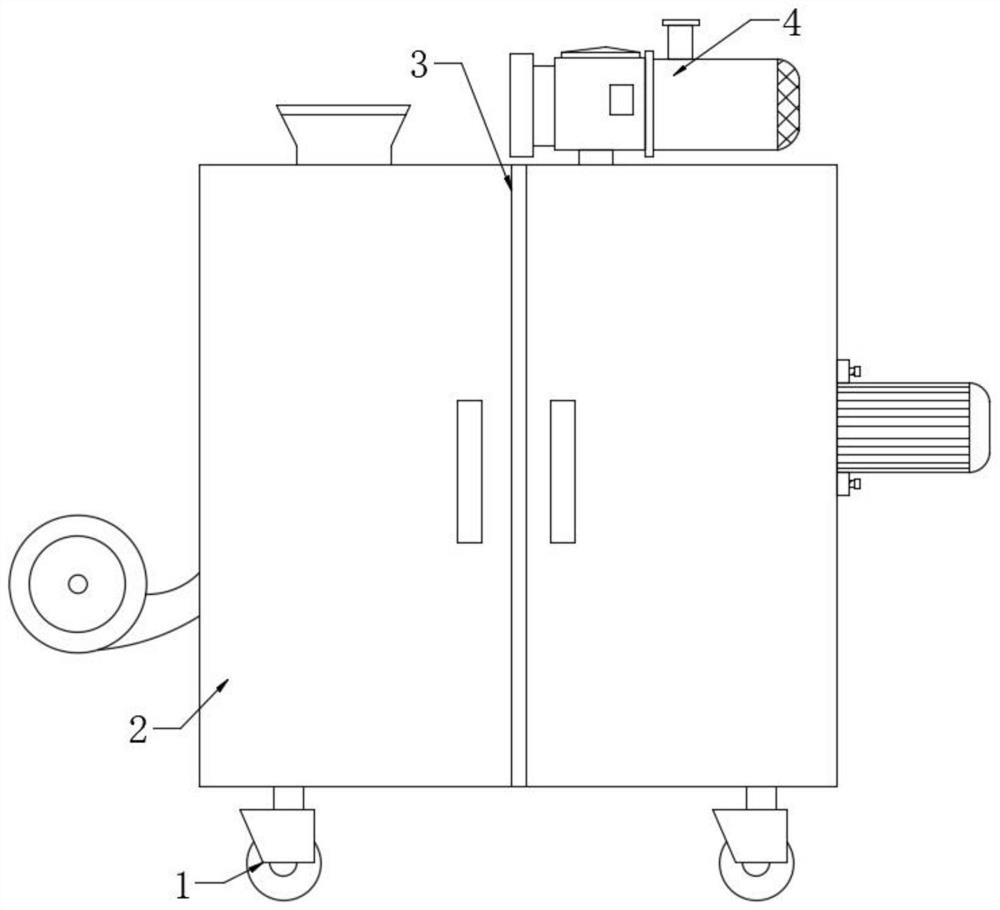

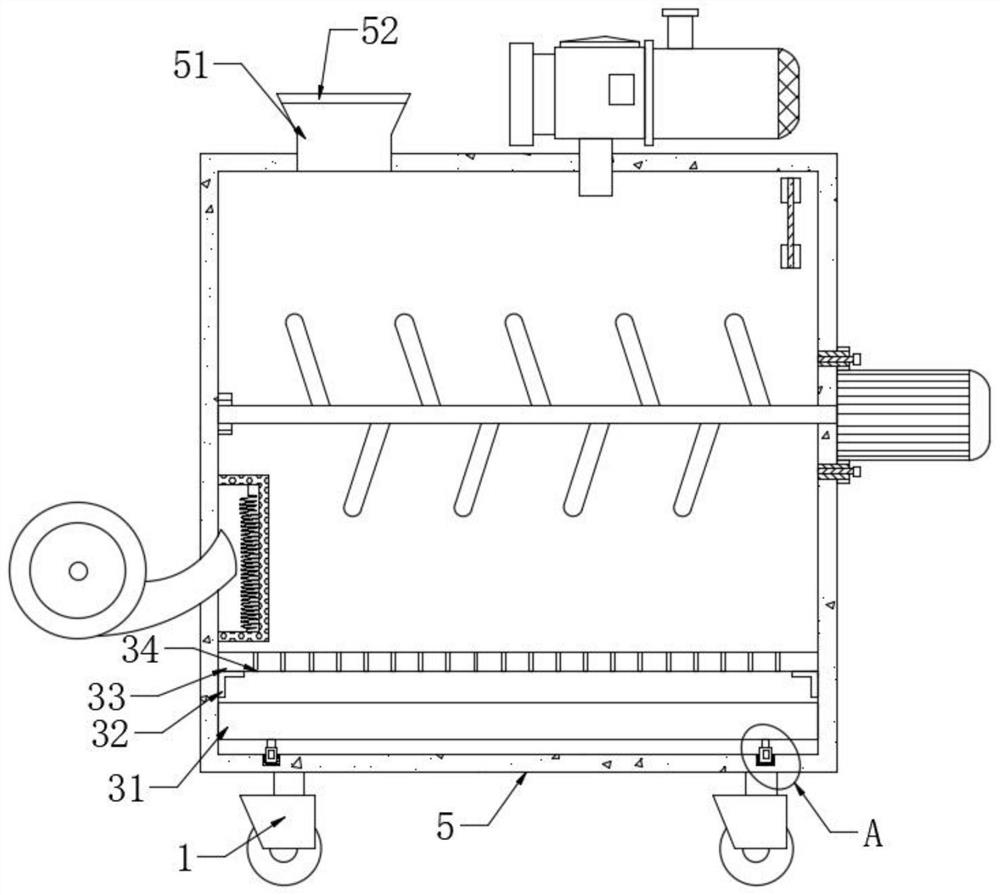

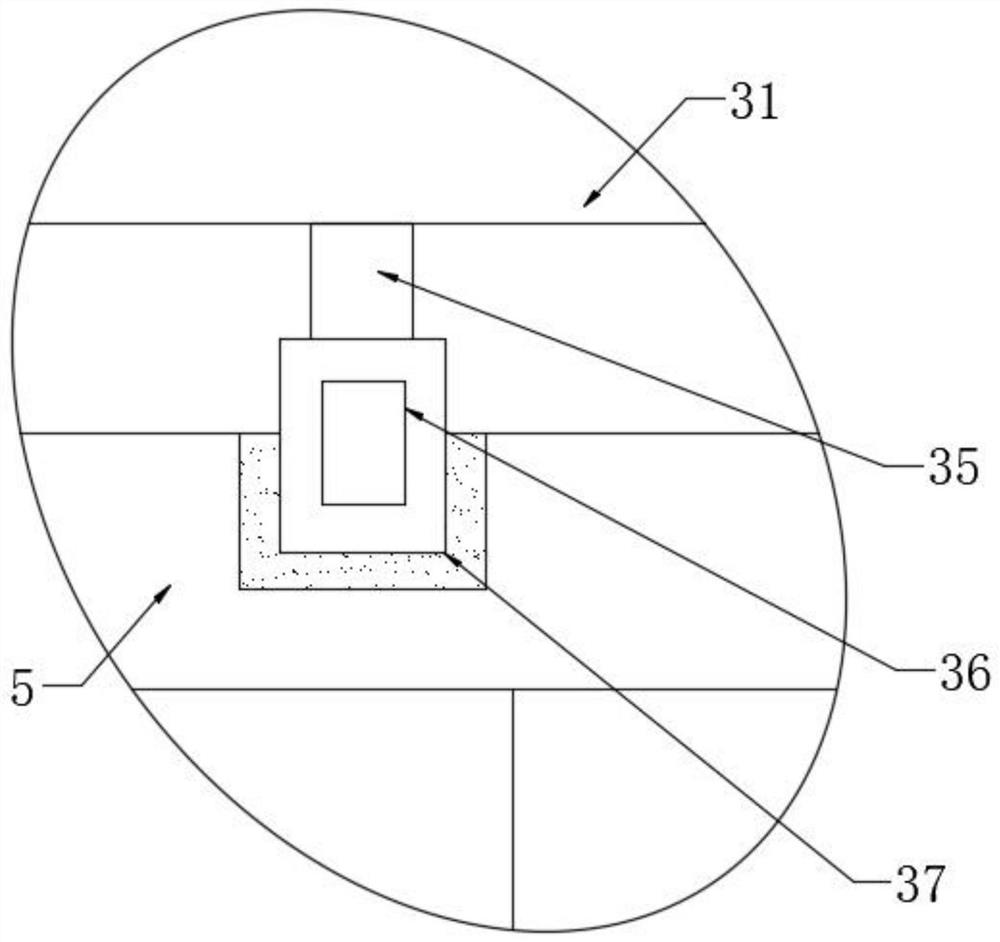

[0024] see Figure 1-Figure 4 , the present invention provides a technical solution: a drying and dehumidifying device for rice processing, comprising a universal wheel 1, a front door panel 2, a cleaning mechanism 3, a drying mechanism 4 and a drying box 5, and the universal wheel 1 is arranged in the drying box 5 lower end face, the front door panel 2 is arranged on the front end face of the drying box 5, the cleaning mechanism 3 is arranged inside the drying box 5, the drying mechanism 4 is arranged on the inside and the outer end surface of the drying box 5, and the cleaning mechanism 3 includes a dust collecting box 31, an angle iron 32. Stainless steel filter screen 33, filter hole 34, connecting column 35, pulley 36 and chute 37, drying mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com