Negative-pressure air inlet cooling device for suspension cylinders of Maerz kiln

A technology of cooling device and hanging cylinder, which is applied in furnace cooling, waste heat treatment, lighting and heating equipment, etc. It can solve the problems of low kiln production stability and high production operation risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

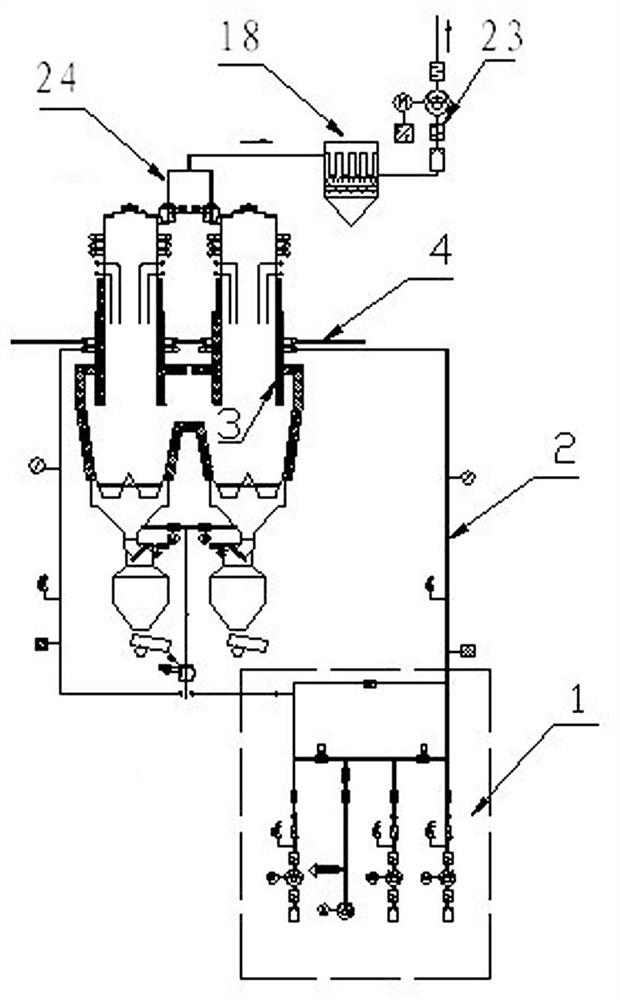

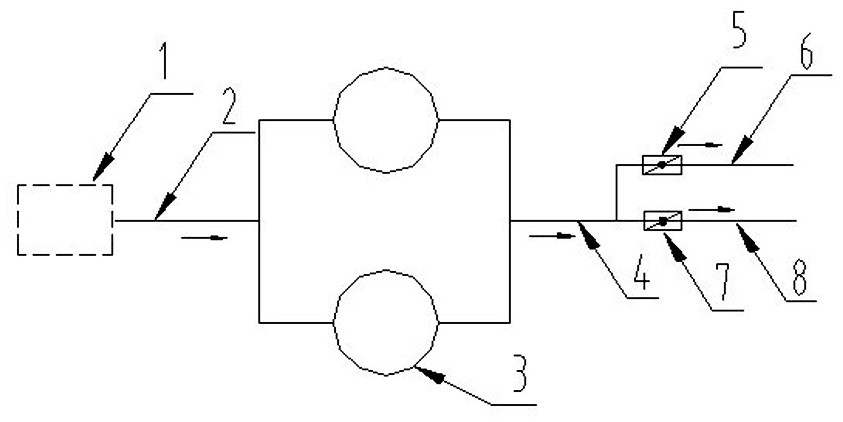

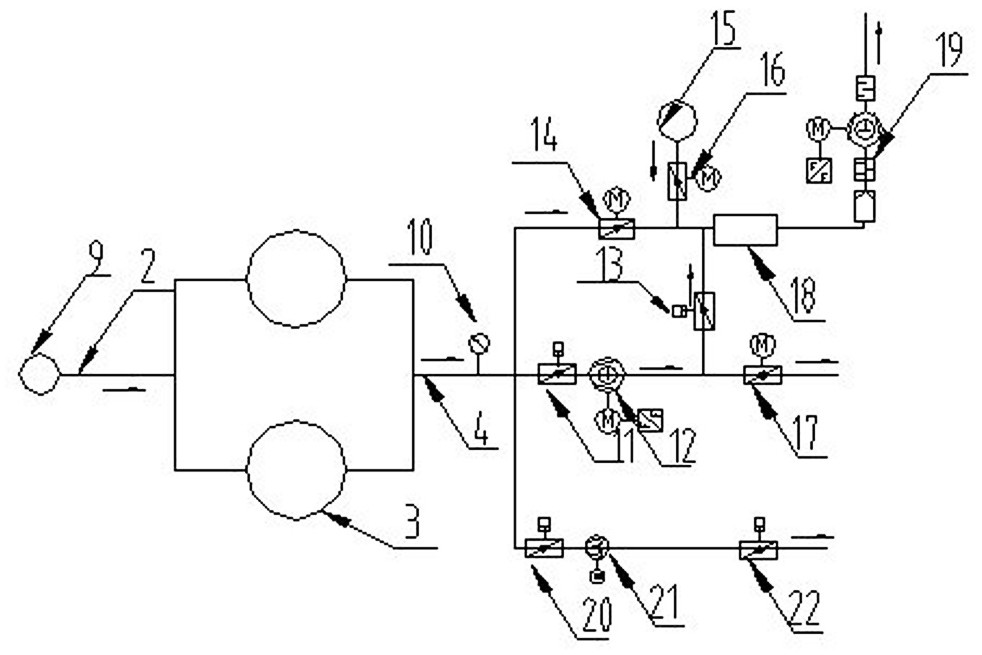

[0021] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0022] Such as image 3 The negative pressure inlet air cooling device for the hanging cylinder of the Maerz kiln includes two hanging cylinders 3 connected in parallel through the hanging cylinder air inlet pipe 2 through the hanging cylinder air inlet pipe filter screen 9, and the air outlet pipe 4 of the two hanging cylinders 3 Connected dust collector box 18. The air outlet pipes 4 of the two suspension cylinders are combined and connected with an electronic thermometer 10, and then divided into branch one, branch two and branch three. Branch one passes through the electric control valve one 14 and then connects the dust collector box 18 and the flue gas dedusting induced draft fan 19 in turn. A side branch extends between the electric control valve one 14 of the branch one and the dust collector box 18, and the side branch Connect the flue g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com