Imaging view field splicing structure

A field of view splicing and imaging technology, which is applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of heavy overall mechanism and complex splicing layout of spectrometers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

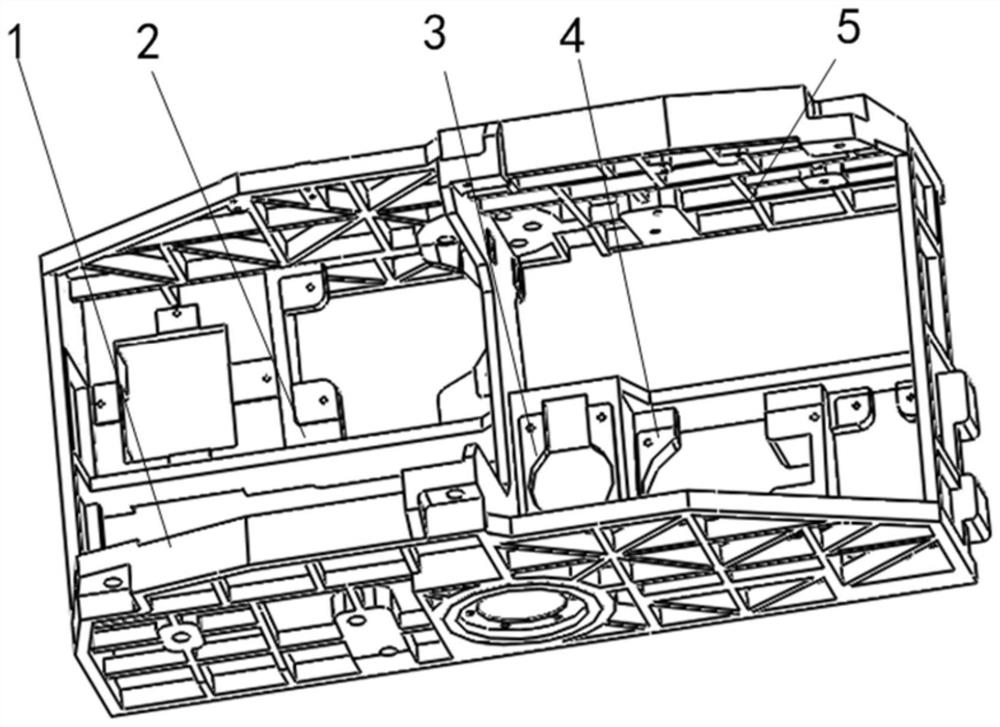

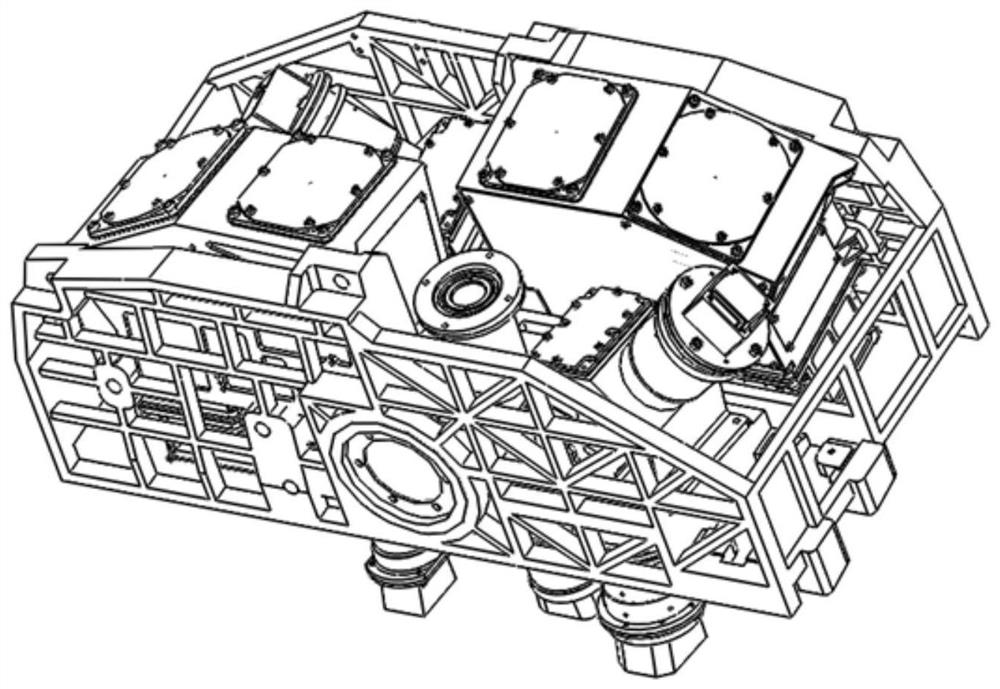

[0015] The structure of the splicing of the imaging field of view of the present invention, its preferred embodiment is:

[0016] It includes the installation flange surface of two infrared spectrometers and the installation flange surface of three visible spectrometers, so as to realize the installation splicing of two infrared spectrometers and three visible spectrometers.

[0017] The splicing angle of the field of view of the two infrared spectrometers is 20°, and the splicing structure of the inner figure of eight is adopted. The angle between the mounting flange of each infrared spectrometer and the ground is 10°;

[0018] The splicing angle of field of view of the three visible spectrometers is 19°. One of the visible spectrometers is a compensation spectrometer, and its mounting flange is parallel to the ground. The angle between the mounting flanges of the other two visible spectrometers is 9.5°. .

[0019] The material of the structure is ZL105.

[0020] The struct...

specific Embodiment

[0027] Such as figure 1 , figure 2 As shown, the field of view of the infrared spectrometer is 20°, and the shape of the inner eight is adopted, and the angle between each flange surface and the ground is 10°. The field of view of the visible spectrometer is spliced at 19°, and the spectrometer at flange surface 3 is a compensation spectrometer to ensure that the splicing field of view of the other two spectrometers is complete, so it is designed to be parallel to the ground, and the spectrometers on flange surfaces 2 and 4 use The angles to the ground are 9.5°, and the splicing of three spectrometers ensures the integrity of the splicing of the large field of view.

[0028] Specific implementation steps:

[0029] 1) Material selection:

[0030] The material selection of this structure mainly considers the strength and processing stability. Considering the overall weight, the material selection is ZL105. L105 has good casting performance and high air tightness, good mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com