Reagent storage switching mechanism for fully automatic analyzers

A technology of automatic analyzer and conversion mechanism, applied in the direction of analyzing materials, instruments, etc., can solve the problem of long transit time and other problems, and achieve the effect of simple structure, high reliability and shortening of travel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

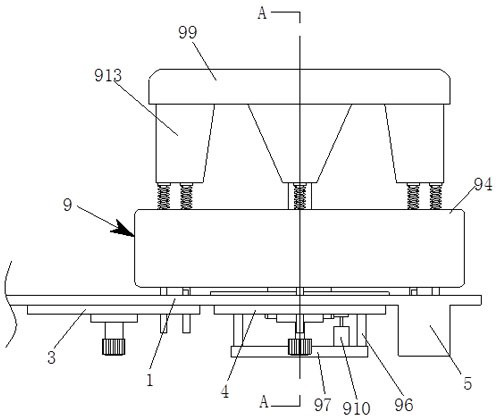

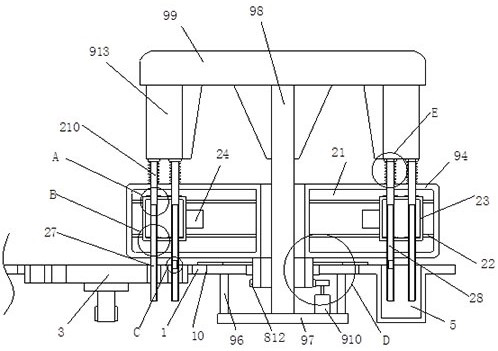

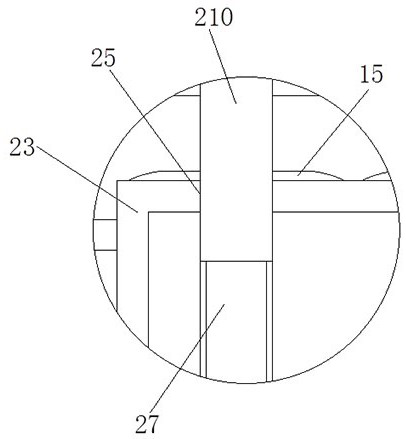

[0028] see Figure 1-10 , the present invention provides a technical solution: a reagent storage conversion mechanism for a fully automatic analyzer, including an analyzer upper shell 1 as an installation base, an analyzer upper shell 1 is provided with a mounting hole 10, and the analyzer upper shell 1 is provided with a mounting hole 10. A sample reagent disc 3 is arranged in the round hole 1 on the left side of the shell 1 and the installation hole 10. The sample grooves and reagent discs on the sample reagent disc 3 are distributed inside and outside, and the round hole on the front side of the installation hole 10 on the upper shell 1 of the analyzer There is a reaction plate 4 inside the second, the analyzer upper case 1 is provided with a waste water tank 5 on the right side of the installation hole 10, and the analyzer upper case 1 is provided with a clean water tank 6 on the rear side of the installation hole 10, which is plugged into the installation hole 10 There is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com