Electrolytic cell fault detection system and method

A fault detection and electrolytic cell technology, which is applied in electrolytic process, electrolytic components, radiation pyrometry, etc., can solve the problems of low efficiency of manual detection of electrolytic cell, achieve the effect of reducing detection cost, expanding detection angle of view, and improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Such as figure 1 As shown, the present invention discloses an electrolytic cell fault detection system, including: an acquisition component and a data processing component connected to the acquisition component, the acquisition component is used to obtain the infrared thermal image of the electrolytic cell in real time, and send the infrared thermal image to the data Processing components;

[0051] The data processing component is used to receive and extract the boundary contour and specification information of the electrolytic cell from the infrared thermal image, find the position of the electrode plate of the electrolytic cell according to the specification information, and determine the position of each electrode plate in the infrared The position on the thermal image; based on the position of each polar plate on the infrared thermal image, the average brightness of each polar plate on the infrared thermal image is counted, and the average brightness of each polar p...

Embodiment 2

[0058] The second embodiment is an extended embodiment of the embodiment, and its difference from the first embodiment is that the structure and function of the electrolyzer fault detection system are refined, including the following:

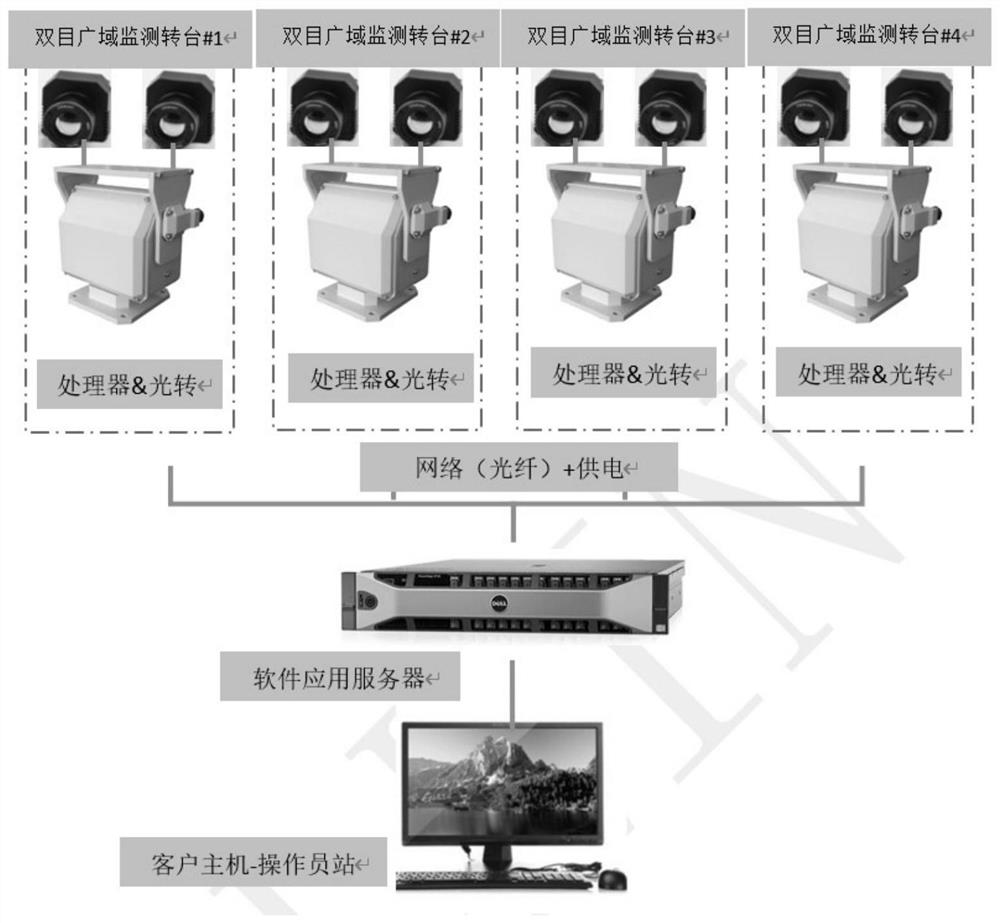

[0059] In this example, if figure 2 As shown, an electrolytic cell fault detection system is disclosed, including multiple sets of acquisition components (ie, the binocular wide-area monitoring turntable in the figure), a data processing component connected to multiple sets of acquisition components, and a client host connected to the data processing components end;

[0060] Among them, the acquisition component includes a precision turntable with horizontal pitch adjustment, a processor, and a binocular infrared detector with a short-focus infrared camera and a long-focus infrared camera fixed on the precision turntable through an optical load platform. The detectors are connected with the data processing components through the processor;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com