Water seepage prevention intermittent ointment filling process

An intermittent, anti-seepage technology, applied in the direction of light guide, optics, instruments, etc., can solve the problems of slowing down the discharge efficiency of ointment in the tube, unable to achieve intermittent oiling, and the ointment is not easy to flow out directly, so as to avoid quality accidents, The production process is easy to operate and the effect of raw material consumption control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

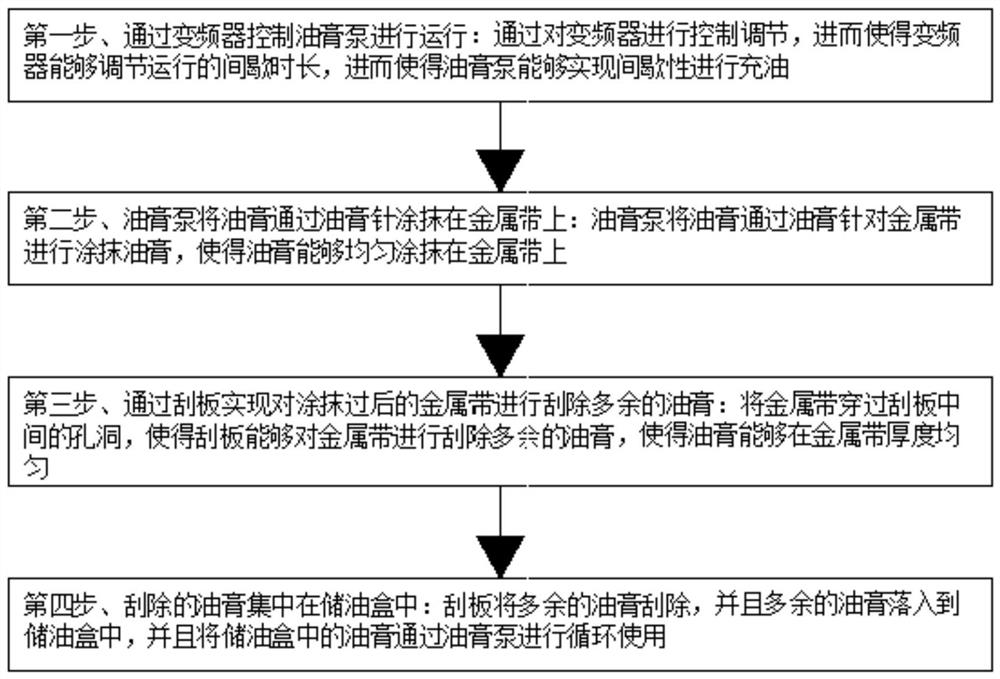

[0027] An anti-seepage water intermittent type ointment filling process comprises the following steps:

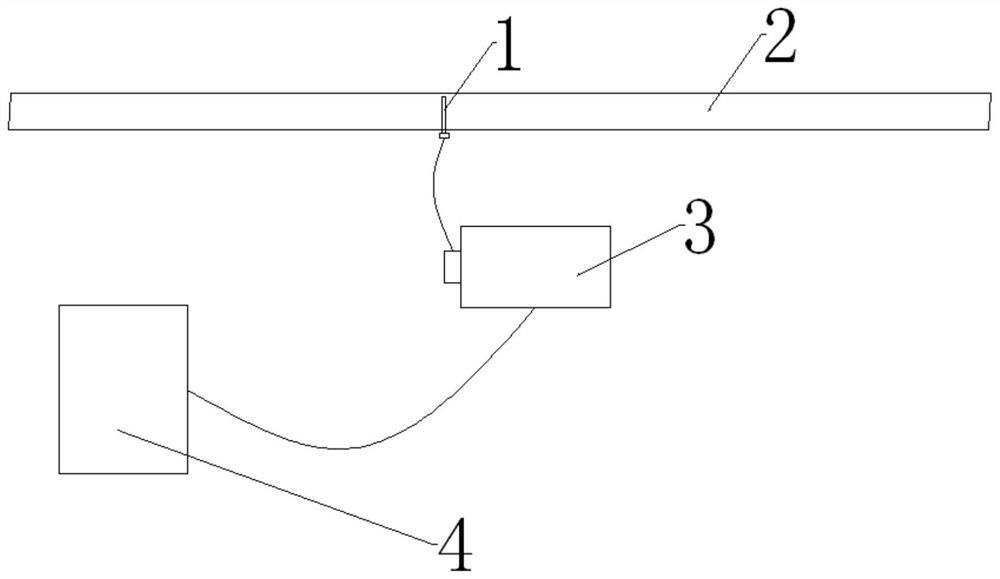

[0028] S1. The operation of the grease pump 3 is controlled by a frequency converter: by controlling and adjusting the frequency converter 4, the frequency converter 4 can adjust the intermittent duration of operation, so that the grease pump 3 can be filled with oil intermittently;

[0029] S2. The ointment pump 3 applies the ointment on the metal belt 2 through the ointment needle 1: the ointment pump 3 applies the ointment on the metal belt 2 through the ointment needle 1, so that the ointment can be evenly applied on the metal strip belt 2 on;

[0030] S3. Realize scraping off excess ointment on the smeared metal strip 2 by means of a scraper: pass the metal strip 2 through the hole in the middle of the scraper, so that the scraper can scrape off excess ointment on the metal strip 2, making The ointment can have a uniform thickness on the metal strip 2;

[0031] S4. T...

Embodiment 2

[0042] An anti-seepage water intermittent type ointment filling process comprises the following steps:

[0043]S1. The operation of the grease pump 3 is controlled by the frequency converter 4: by controlling and adjusting the frequency converter 4, the frequency converter 4 can adjust the intermittent duration of operation, so that the grease pump 3 can be filled with oil intermittently;

[0044] S2. The ointment pump 3 applies the ointment on the metal belt 2 through the ointment needle 1: the ointment pump 3 applies the ointment on the metal belt 2 through the ointment needle 1, so that the ointment can be evenly applied on the metal strip belt 2 on;

[0045] S3. Realize scraping off excess ointment on the smeared metal strip 2 by means of a scraper: pass the metal strip 2 through the hole in the middle of the scraper, so that the scraper can scrape off excess ointment on the metal strip 2, making The ointment can have a uniform thickness on the metal strip 2;

[0046] S4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com