Transformer cooling device

A cooling device and transformer technology, applied in the field of transformers, can solve the problems of dust in high-voltage bushings and the inability of transformers to dissipate heat, and achieve the effects of preventing accumulation, reducing cost, low investment, and increasing practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

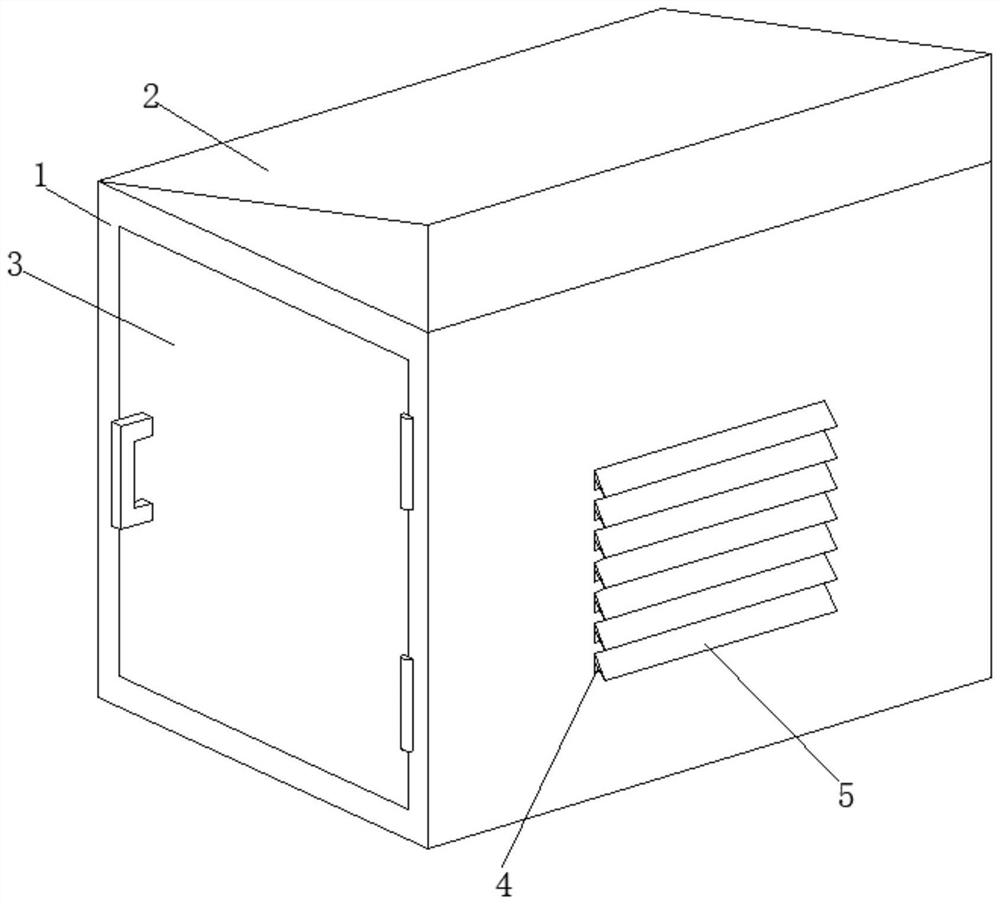

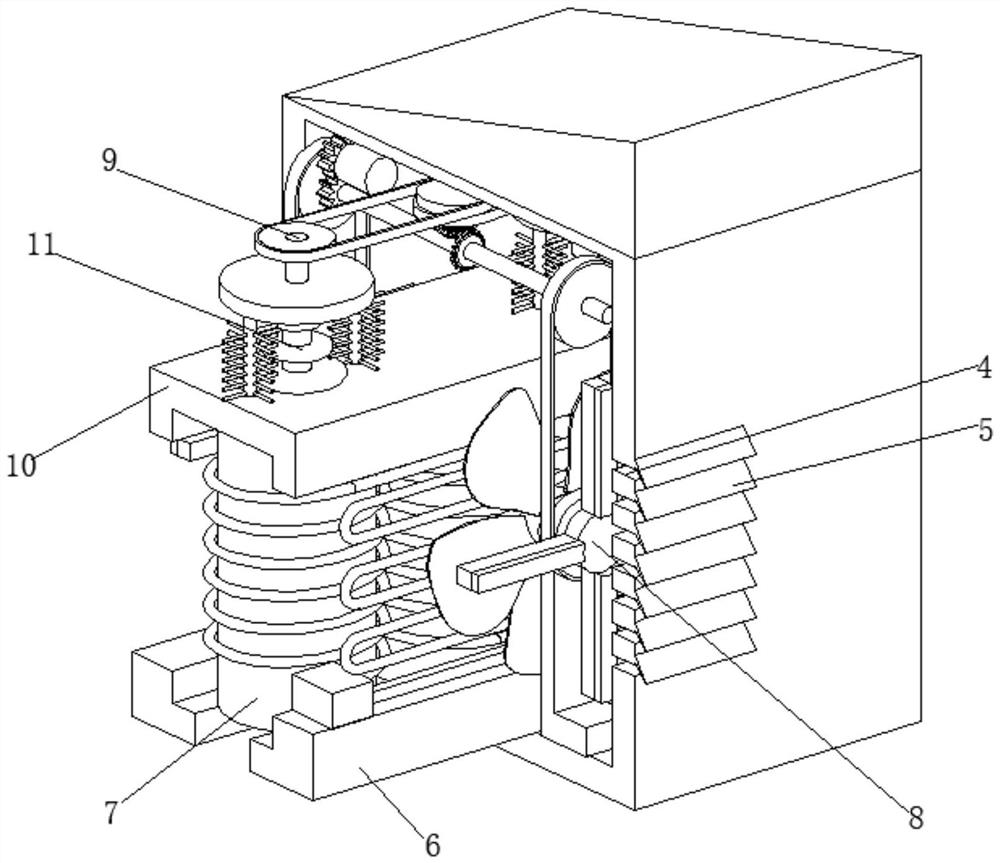

[0031] A transformer cooling device, such as Figure 1-Figure 6 As shown, it includes a box body 1, the top of the box body 1 is welded with an inclined block 2, the front part of the box body 1 is connected with a revolving door 3, and both sides of the box body 1 are provided with several air holes 4, and the box body 1 There are several baffles 5 welded on both sides of the box, and the baffles 5 are located above the air holes 4, the bottom wall inside the box 1 is connected with a base 6 by bolts, the upper surface of the base 6 is fixedly equipped with a coil 7, the box 1 The inner wall of the box body 1 is provided with a cooling mechanism 8, the top wall inside the box 1 is provided with a cleaning mechanism 9, the top of the coil 7 is fixedly installed with a top plate 10, and the top of the top plate 10 is clamped with a high-voltage bushing 11.

[0032] In this embodiment, there are two bases 6, and the two bases 6 are symmetrically distributed with the center line ...

Embodiment 2

[0041] Such as Figure 6-Figure 7 As shown, on the basis of Embodiment 1, in this embodiment, the axis of the turntable 861 and the axis of the first pulley 85 are welded and fixed, and the surface of the water-absorbing sponge 863 is in contact with the inner wall of the box body 1 .

[0042] The water-absorbing sponge 863 can absorb rainwater that cannot be blocked by the baffle plate 5, and prevent rainwater from entering the coil 7, thereby causing the transformer to break down and affecting the service life of the transformer.

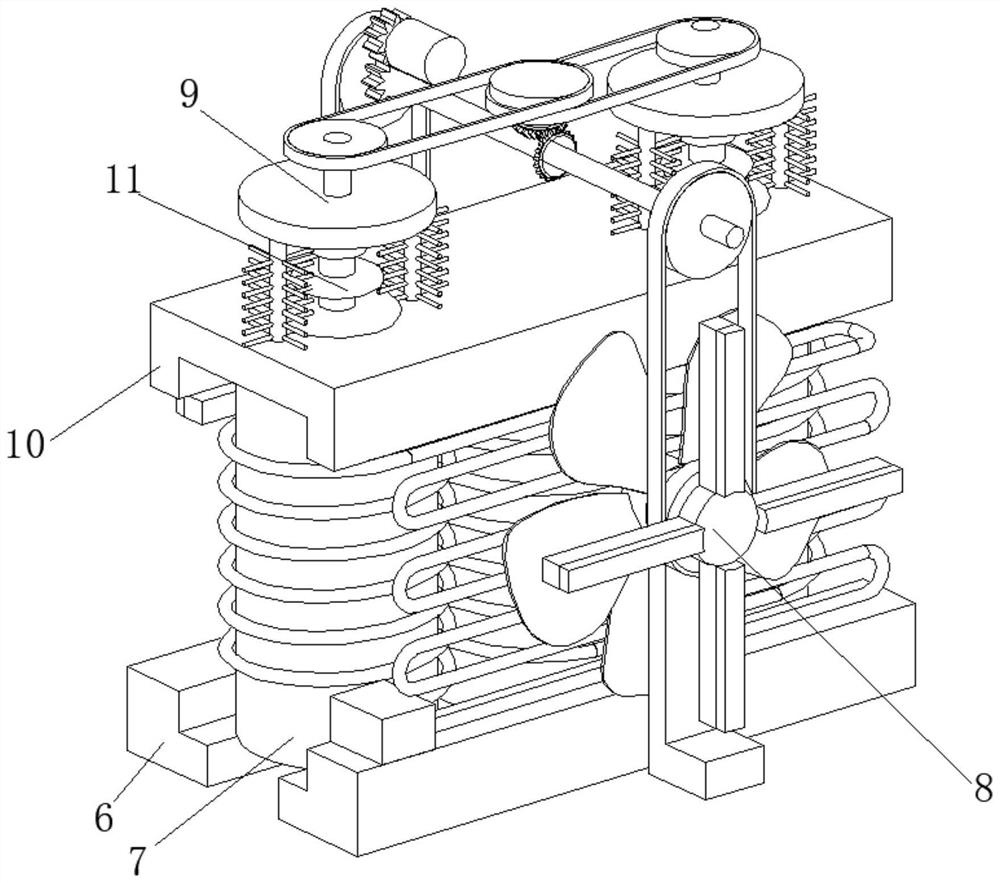

[0043] The cleaning mechanism 9 includes a double-layer pulley 91, and the shaft center of the double-layer pulley 91 is welded with a No. 2 bevel gear 92 through a connecting rod. Transmission connection, the axis of the first pulley 93 and the second pulley 94 are welded with a runner 95 through a connecting rod, the bottom of the runner 95 is welded with two connecting rods 96, and the surface of the connecting rod 96 is inserted with several b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com