An agricultural straw treatment and reuse device

A straw and agricultural technology is applied in the field of agricultural straw treatment and reuse devices, which can solve the problems of increasing straw treatment steps, low straw treatment efficiency, and low straw treatment degree, and achieves reduction of treatment time, simple cutting process, and saving of pre-processing. The effect of processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

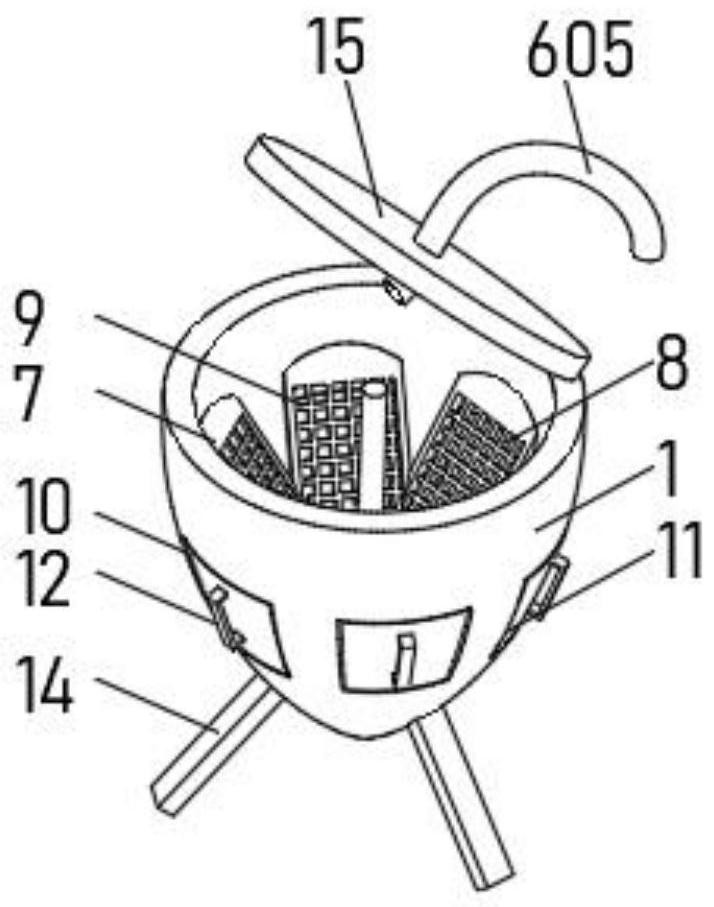

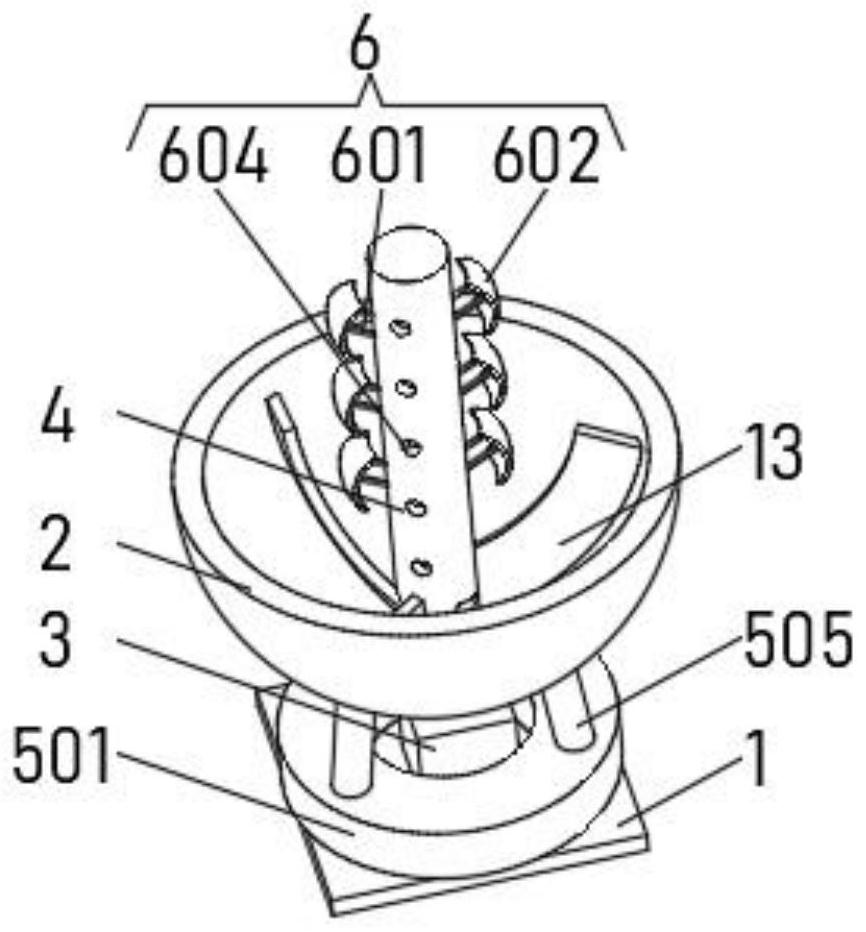

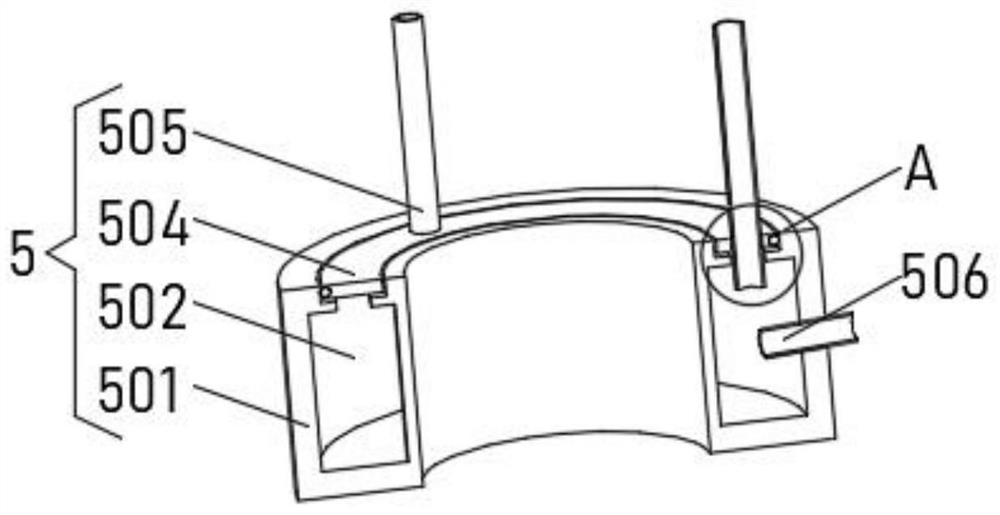

[0030] see Figure 1-5, the present invention provides a technical solution: an agricultural straw treatment and reuse device, comprising a housing 1, the housing 1 is a hollow spherical structure with an open top, the inner wall of the housing 1 is rotatably connected with an isolation chassis 2, and the inner bottom of the housing 1 is fixedly connected There is a rotating motor 3, and the output end of the rotating motor 3 is connected to a central rod 4, and the end of the central rod 4 away from the rotating motor 3 penetrates the isolation chassis 2 and extends to the top of the isolation chassis 2, and a lifting device 5 is installed on the inner bottom of the shell 1 One end of the top of the lifting device 5 runs through the isolation chassis 2, and the end of the central rod 4 located at the isolation chassis 2 is evenly equipped with a pusher device 6, and the inner wall of the shell 1 is evenly equipped with a cutting frame 7 above the isolation chassis 2. A longit...

Embodiment 2

[0037] see Figure 1-5 , the present invention provides a technical solution: on the basis of Embodiment 1, a pushing chamber 603 is provided inside the central rod 4, and a pushing port 604 is evenly opened on the outside of the central rod 4, and the pushing port 604 is connected with the pushing chamber 603 communicates, the top of the central rod 4 communicates with a delivery pipe 605 , the delivery pipe 605 runs through the central rod 4 and is rotationally connected with the central rod 4 .

[0038] The inner diameter of the pushing port 604 gradually decreases toward the direction away from the pushing chamber 603, and the end of the pushing port 604 away from the pushing chamber 603 is fixedly connected with an isolation net 606, and the outer side of the central rod 4 is fixedly connected with a protective net above the isolation net 606. The plate 607, the protective plate 607 is arranged obliquely downward.

[0039] When in use, water is delivered from the deliver...

Embodiment 3

[0041] see Figure 1-5 , the present invention provides a technical solution: on the basis of Embodiment 1, an upper rotary knife 13 is evenly installed on the inner bottom of the isolation chassis 2, and the upper rotary knife 13 is the same as the inner radian of the isolation chassis 2, and the upper rotary knife 13 is directed to Set on one side with a slant.

[0042] When in use, the rotating motor 3 starts to drive the central rod 4 and the isolation chassis 2 to rotate at the same time, and the inclined upper rotary knife 13 on the top of the isolation chassis 2 swings the straw on the isolation chassis 2 obliquely upward during the rotation of the isolation chassis 2 , the straw is sent to the top to collide with the pusher plate 602 and the cutting knife for cutting, which can assist in lifting the straw upwards to ensure that the straw can be lifted and cut, and avoid too much straw in the casing and the jet pipe 505 cannot be pushed upward, causing the straw to accu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com