Drawing equipment and process for stainless steel machining

A technology of drawing equipment and stainless steel, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as human injury, threat to the safety of construction personnel, and shorten the aftertaste time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

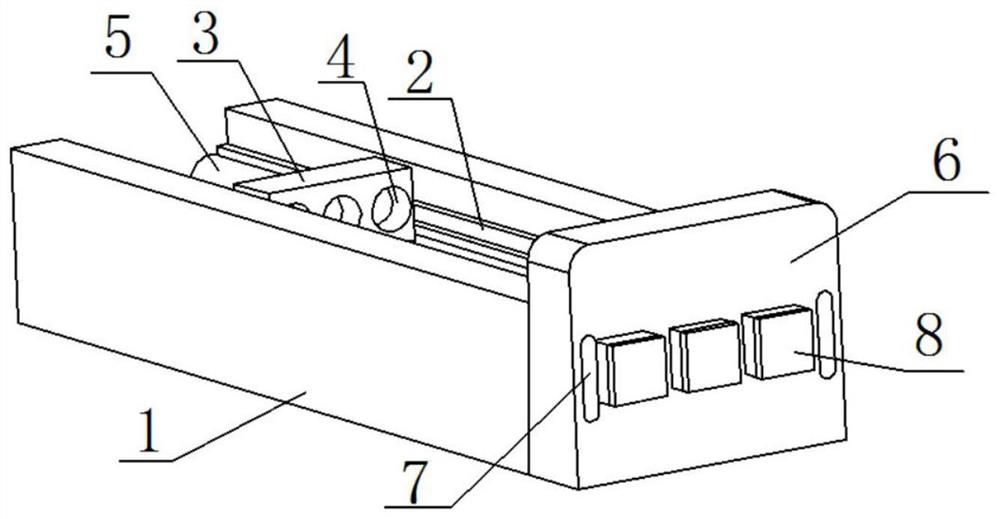

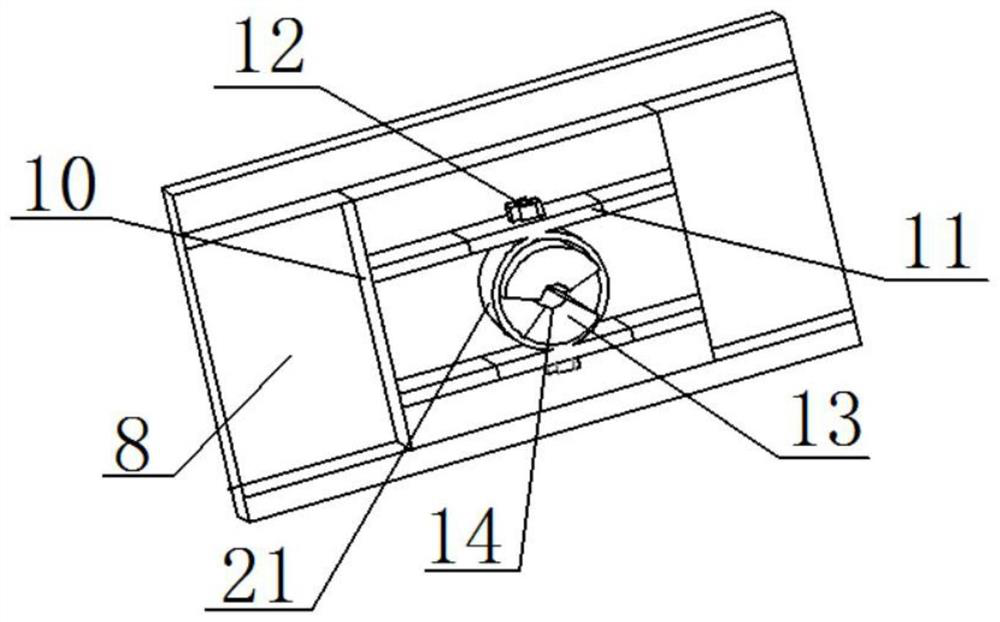

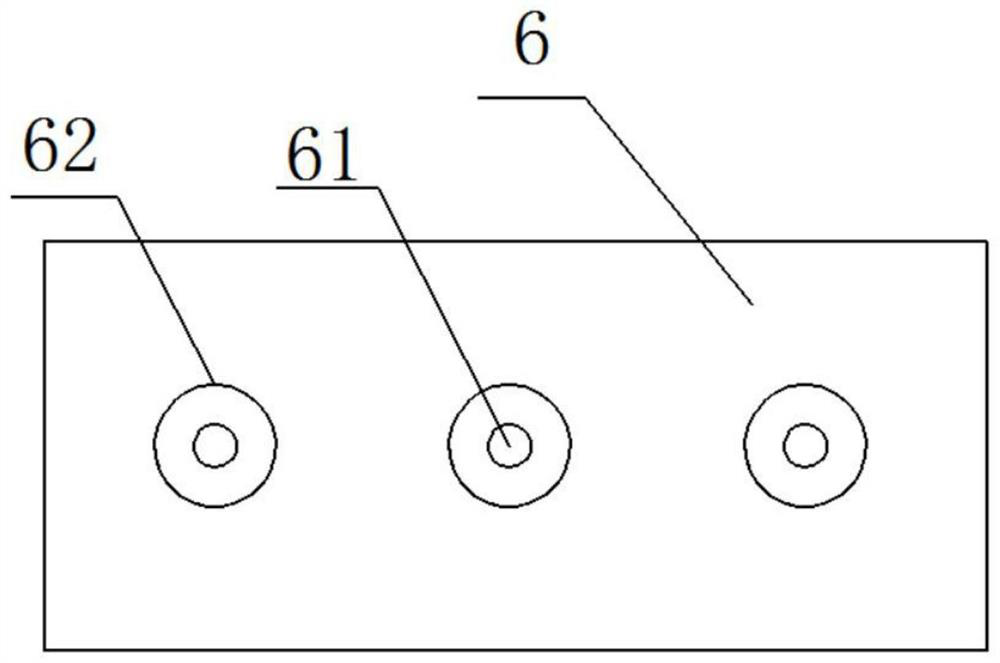

[0038] The horizontal hydraulic broaching machine 1 adopts the L6115 model horizontal hydraulic broaching machine, and the horizontal hydraulic broaching machine 1 is connected to an external power device, and the power device is connected to an external power supply to form an electric drive, and the horizontal hydraulic broaching machine Type hydraulic broaching machine 1 is connected with an external control device to realize pulling force control, and then the front end of the stainless steel pipe to be drawn that is ready for cleaning is pushed to the protective cover 9, and the protective cover 9 generates a certain angle on the surface of the hinge after being stressed. Rotate, so that the protective cover 9 moves upward until one side surface of the protective cover 9 fits the inner wall of the protective device 8. At this time, the stainless steel pipe passes through the positioning ring 21 on the surface of the protective plate 10, and the two symmetrically installed p...

Embodiment 2

[0043] The horizontal hydraulic broaching machine 1 adopts the L6115 model horizontal hydraulic broaching machine, and the horizontal hydraulic broaching machine 1 is connected to an external power device, and the power device is connected to an external power supply to form an electric drive, and the horizontal hydraulic broaching machine Type hydraulic broaching machine 1 is connected with an external control device to realize pulling force control, and then the front end of the stainless steel pipe to be drawn that is ready for cleaning is pushed to the protective cover 9, and the protective cover 9 generates a certain angle on the surface of the hinge after being stressed. Rotate, so that the protective cover 9 moves upward until one side surface of the protective cover 9 fits the inner wall of the protective device 8. At this time, the stainless steel pipe passes through the positioning ring 21 on the surface of the protective plate 10, and the two symmetrically installed p...

Embodiment 3

[0048]The horizontal hydraulic broaching machine 1 adopts a YS-OT type horizontal hydraulic broaching machine, and the horizontal hydraulic broaching machine 1 is connected to an external power device, and the power device is connected to an external power source to form an electric drive, and the The horizontal hydraulic broaching machine 1 is connected with an external control device to realize pulling force control, and then the front end of the stainless steel pipe to be drawn that is ready for cleaning is pushed to the protective cover 9, and the protective cover 9 generates a certain force on the surface of the hinge after being stressed. Angle rotation, thus the protective cover 9 moves upward until one side surface of the protective cover 9 fits the inner wall of the protective device 8. At this time, the stainless steel pipe passes through the positioning ring 21 on the surface of the protective plate 10, and the two symmetrically installed pressure sensors The linear ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com