A phase change engine exhaust flame temperature testing device and control method

A test control and test device technology, applied in the field of phase change engine temperature test, to achieve the effect of optimizing infrared radiation characteristics, eliminating human bias, and accurate temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

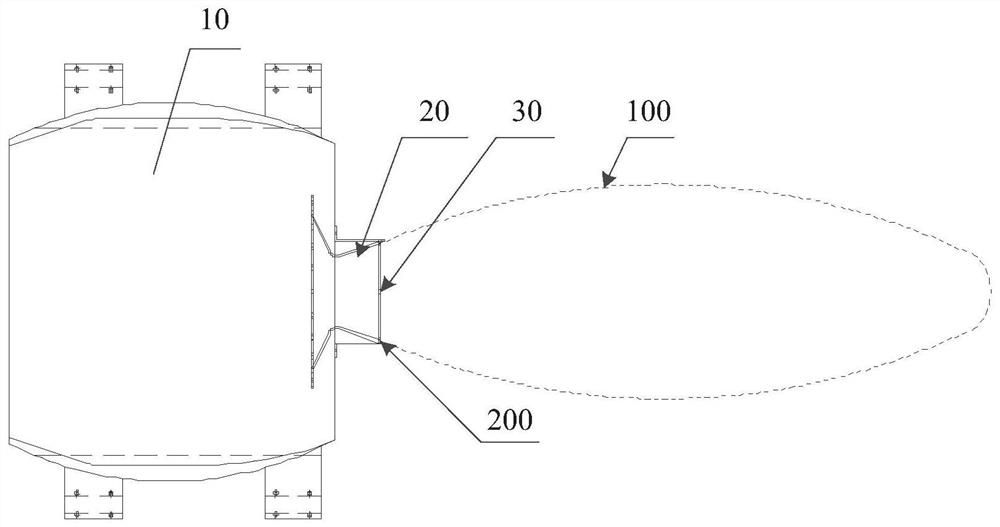

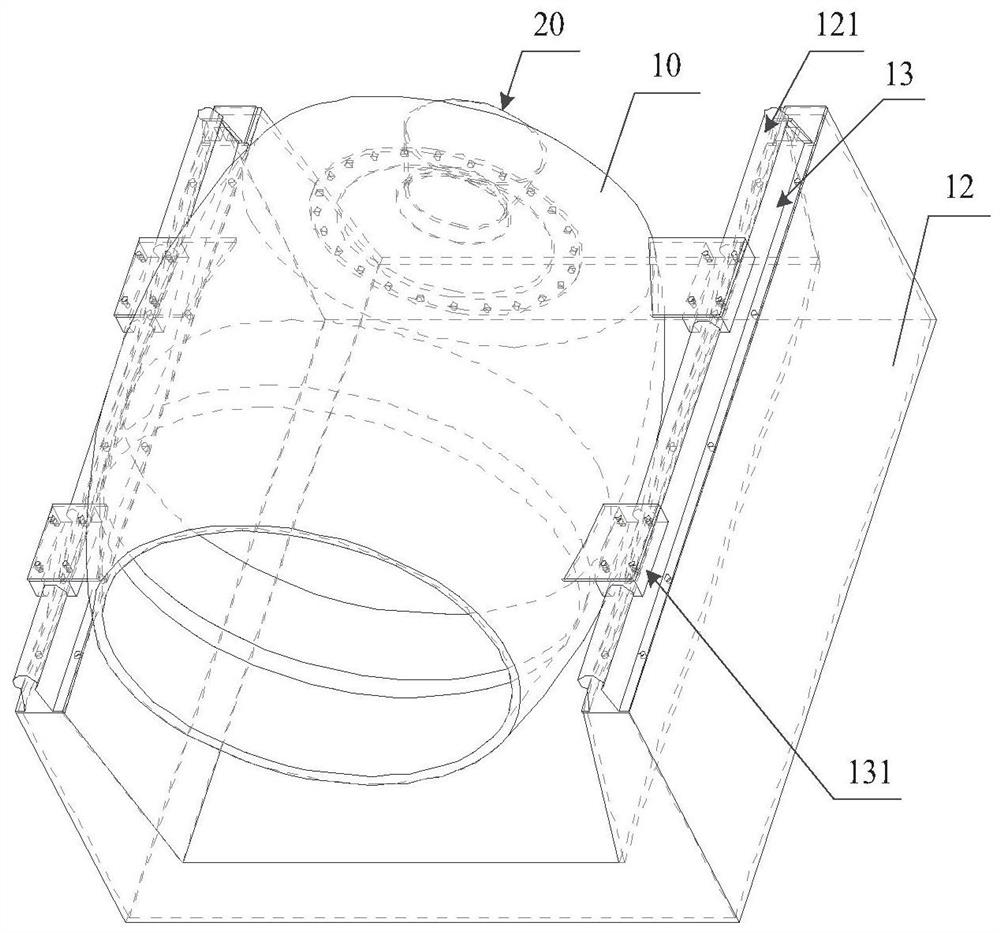

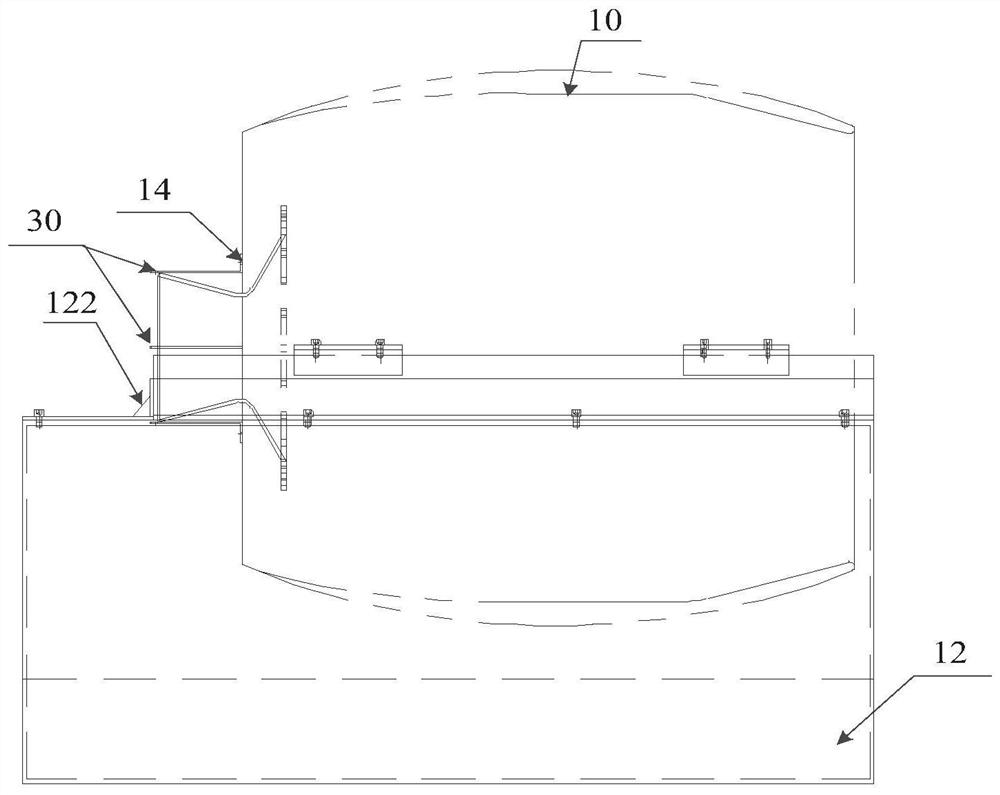

[0050] Such as Figure 1 to Figure 5 As shown, the first embodiment of the present invention proposes a phase change engine tail flame temperature testing device, including an engine combustion chamber 10, an air injection port 20, a temperature calibration sensor 30, an infrared thermometer 40 and a controller 50, wherein the air injection port 20 is connected with the engine combustion chamber 10, and is used for injecting phase-change engine tail flame 100; The quantity of temperature calibration sensor 30 is a plurality of, and a plurality of temperature calibration sensors 30 are circumferentially placed at the outlet of the jet port 20, for Sensing the temperature of phase change engine tail flame 100 in all directions to calibrate the phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com