Modeling method for coaxial silicon through hole filled with a single-walled carbon nanotube

A single-walled carbon nanotube and carbon nanotube technology, applied in the field of electronics, can solve the problems of decreased electrical transmission performance, complicated calculation, insufficient circuit model accuracy, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

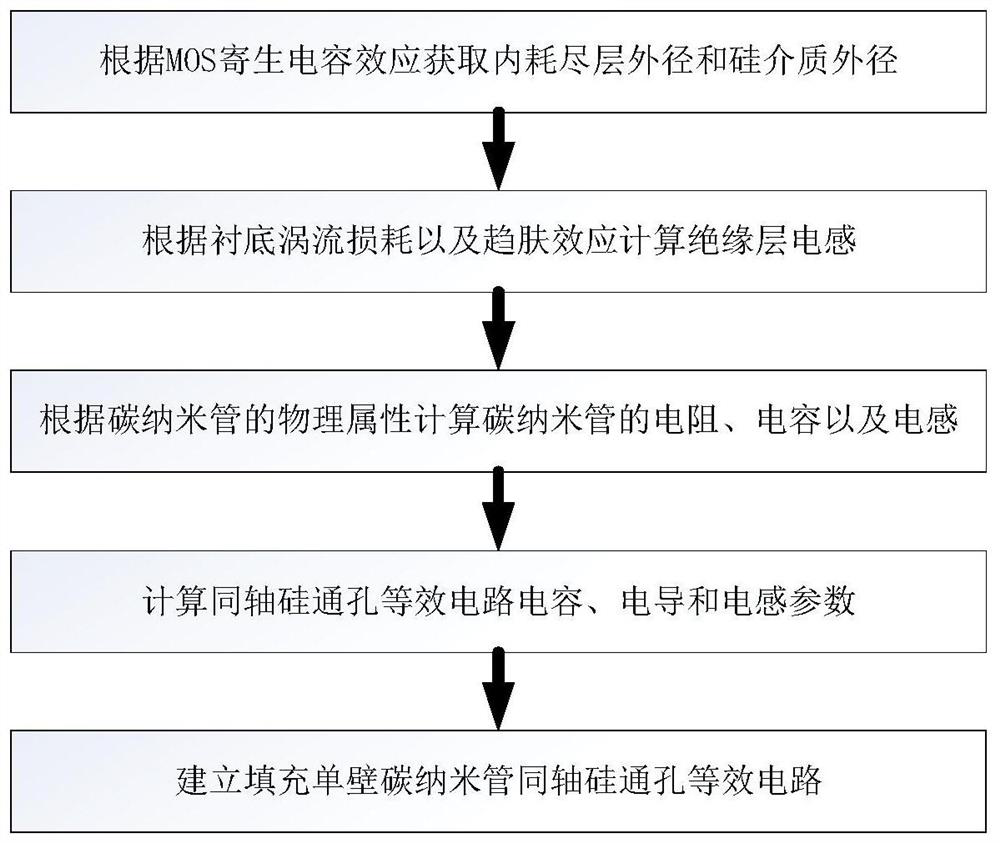

[0024] refer to figure 1 , further describe the steps realized by the present invention.

[0025] Step 1, calculate the outer diameter of the inner depletion layer and the outer diameter of the silicon dielectric according to the MOS parasitic capacitance effect.

[0026] The calculation of the outer diameter of the inner depletion layer and the outer diameter of the silicon medium includes:

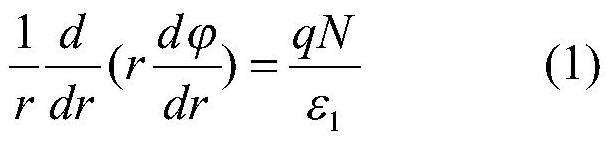

[0027] Set the expression and boundary conditions of the one-dimensional Poisson equation in the cylindrical coordinate system;

[0028] Integrate the expression according to the boundary conditions to obtain the outer diameter r of the inner depletion layer 1 and silicon dielectric outer diameter r 3 .

[0029] Step 2, calculate the inductance of the insulating l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com