Preparation method, product and application of a positive electrode pre-lithiation material

A positive electrode and lithiation agent technology, which is applied in the field of preparation of positive electrode pre-lithiation materials, can solve the problems of low specific capacity, decomposition and gas production, etc., and achieve the effects of improved stability, high safety, and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Preparation method of pre-lithiation agent pole piece

[0032] Me / LiF / Li 2 Mix O and conductive agent (Super~P) evenly, then add polyvinylidene fluoride (PVDF) binder, add a certain amount of N-methylpyrrolidone (NMP), grind evenly, and apply the above mixed slurry on the current collector (such as an aluminum foil current collector), bake at 60° C. and an inert atmosphere for 4 hours, for example, to obtain the required pre-lithiated electrode sheet. Wherein, the formula of the pole piece is (mass ratio) may be pre-lithiation agent: Super~P:PVDF=7:2:1.

[0033] Positive electrode sheet preparation

[0034] Mix the positive electrode active material, pre-lithiation agent and conductive agent (Super~P) evenly, then add polyvinylidene fluoride (PVDF) binder, drop a certain amount of N-methylpyrrolidone (NMP), grind evenly, The above-mentioned mixed slurry is evenly coated on the aluminum foil current collector, and baked at 80° C. under vacuum conditions for 4 hours, f...

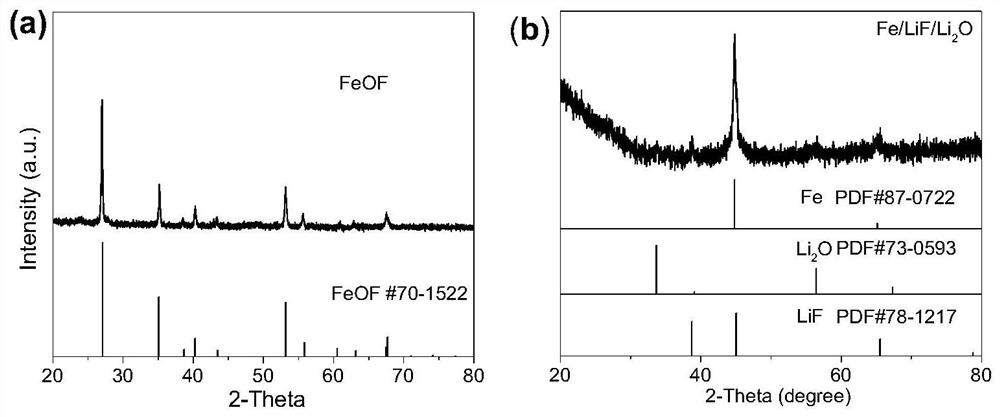

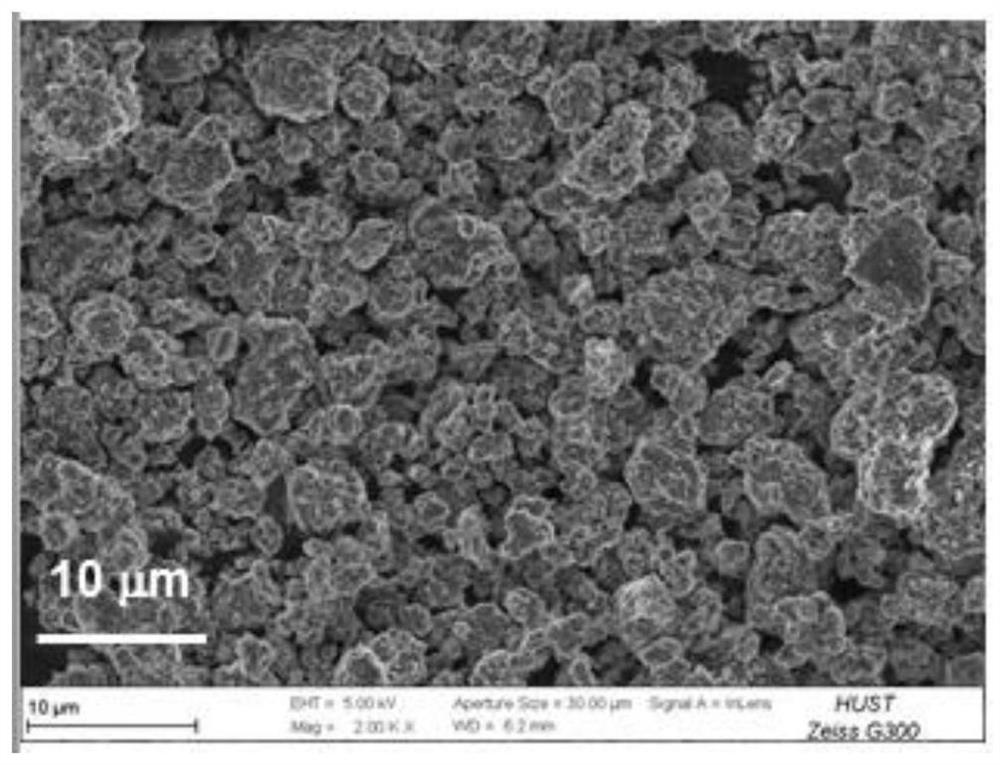

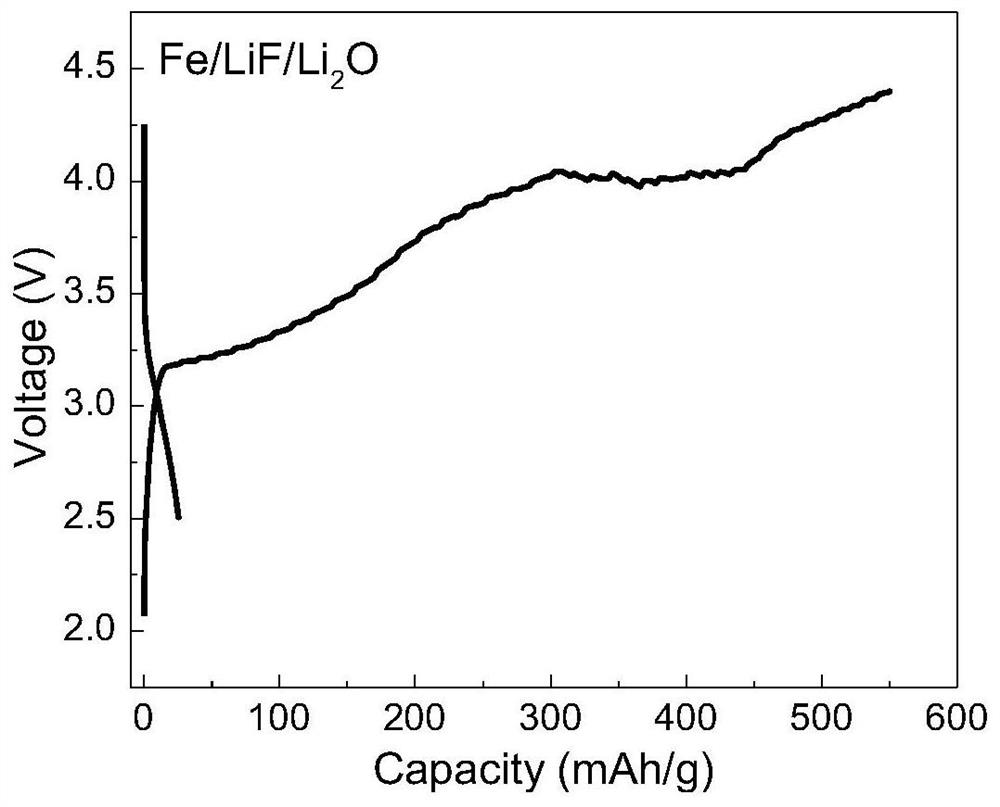

Embodiment 1

[0041] Weigh 0.3g FeF 3 After the hydrate was ground in a mortar, it was transferred to a hydrothermal kettle with a capacity of 100mL, and then 75mL of n-propanol was added, sealed and placed in an oven at 200°C for 24h. After the reaction, it was taken out, washed with ethanol, centrifuged three times, and dried in an oven at 60° C. to obtain FeOF solid powder. Then, 0.15 g of FeOF and 0.048 g of metal lithium were weighed in an Ar atmosphere glove box, placed on a heating platform, and molten metal lithium and FeOF were mechanically mixed and reacted at 300° C. After reacting for 1 hour, lower the temperature, and collect black Fe / LiF / Li with a carbon-containing coating layer and a particle size of 2 μm to 20 μm. 2 O powder, Fe, Li 2 The molar ratio of O and LiF satisfies 1:x:y, and 2x+y≤3. Take 7mg of Fe / Li 2 The O / LiF additive was mixed with 2 mg conductive agent (Super~P) and 20 mg PVDF (5wt% PVDF / NMP solution), homogenized, coated, dried in vacuum at 60 ° C, punched...

Embodiment 2

[0044] Weigh 0.3g CoF 3 After the hydrate was ground in a mortar, it was transferred to a hydrothermal kettle with a capacity of 100mL, and then 75mL of n-propanol was added, sealed and placed in an oven at 200°C for 24h. After the reaction, it was taken out, washed with ethanol, centrifuged three times, and then dried in an oven at 60°C to obtain CoOF solid powder. Then, 0.15 g of CoOF and 0.048 g of metal lithium were weighed in an Ar atmosphere glove box, placed on a heating platform, and molten metal lithium and CoOF were mechanically mixed and reacted at 300 ° C. After reacting for 1 hour, lower the temperature, and collect the obtained black Co / LiF / Li 2 O powder, Co, Li 2 The molar ratio of O and LiF satisfies 1:x:y, and 2x+y≤3. Take 7mg of Co / Li 2 The O / LiF additive was mixed with 2 mg conductive agent (Super~P) and 20 mg PVDF (5wt% PVDF / NMP solution), homogenized, coated, dried in vacuum at 60 ° C, punched into pole pieces with a diameter of 10 mm, and Metal lithi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com