China-hemp cutting flexible driving double-layer cutter bar moving cutter component

A technology for hemp cutting flexible and driving rods, which is applied in the field of flexible driving double-layer knife rod moving knife parts, and can solve the problems of single-layer knife rods that are easy to bend or break, poor bast fiber cutting effect, and low operating efficiency. Achieve the effect of good cutting quality and effect, remarkable technical effect and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

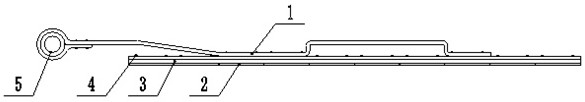

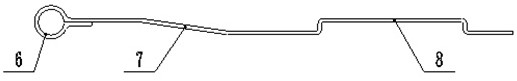

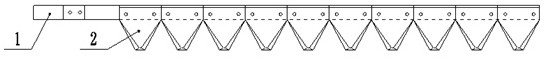

[0014] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A flexible driving double-layer knife rod moving knife part for hemp cutting. The flexible driving rod 1 is sequentially connected by a connecting ring 6, a flexible section 7 and an anti-interference raised section 8 of the pressing blade part. In the connecting ring 6 The connecting sleeve 5 of the ring box is fixed inside, and the rigid knife bar 4, the flexible knife bar 3 and the cutting blade 2 are fixed sequentially from top to bottom on the lower side of the flexible driving rod 1 through a riveting structure. The blade thickness H of the cutting blade 2 is 3 millimeters, the included angle α of the bilateral cutting blades is 56°, and the angle β between the cutting front line of the cutting blade and the vertical direction of the blade is 2°.

[0015] When in use, the hemp cutting flexible drive double-layer knife rod moving knife part assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com