Cleaning mechanism of automated optical inspection (AOI) equipment

A technology of cleaning mechanism and testing equipment, which is applied in the direction of cleaning method, cleaning method and utensils, and cleaning devices using gas flow, which can solve problems such as inability to meet production needs, inaccurate detection results, and increased defective product rate, and achieve The structure is simple, the detection efficiency is improved, and the effect of avoiding false detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further described below in conjunction with the accompanying drawings and examples;

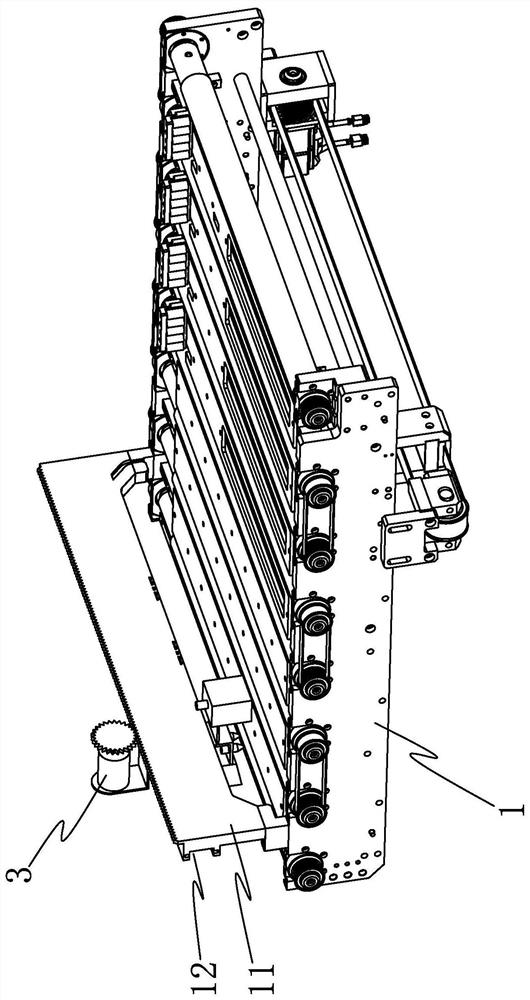

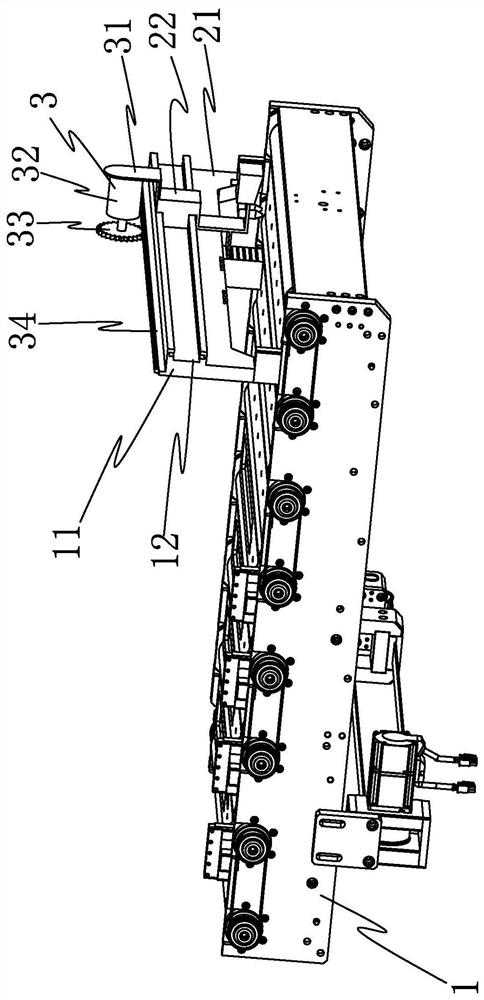

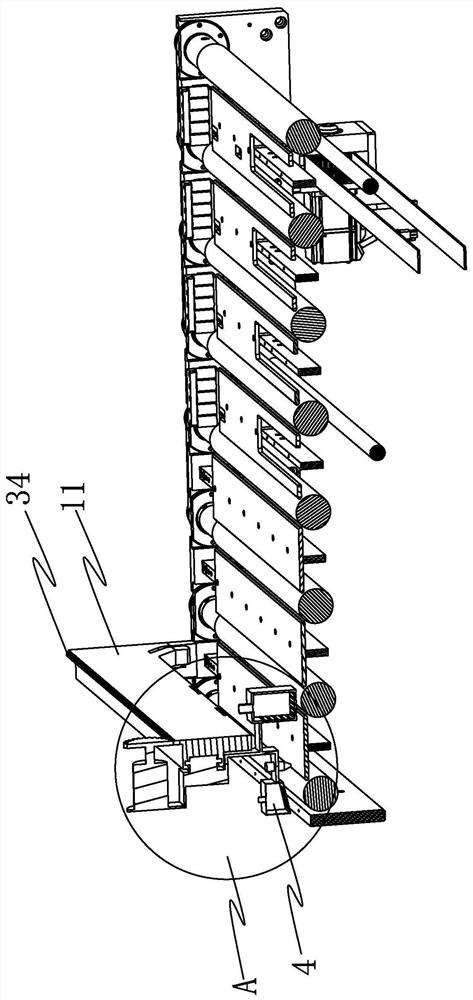

[0018] See Figure 1 - Figure 4 A cleaning mechanism of an AOI detection device includes a gantry 11 disposed on the conveyor 1, and is provided with a guide rail 12 on the gantry 11, and the moving block 22 is inserted in the guide rail 12, in the The moving block 22 is provided with a moving assembly 3 for driving the moving block 22 along the guide rail 12, and a mounting frame 20 is provided on the moving block 22, and the mounting frame 20 is provided with a cleaning assembly 4, which can be moved The component drives the moving block movement, which can drive the cleaning assembly to move while moving the PCB on the conveyor, which may increase the detection efficiency and the accuracy of the detection, avoiding an error detection, causing the good product to become a non-good product, simple structure, in line with the use Required;

[0019] See Figure 1 - Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com