Automatic feeding machine tool workpiece detection method

A technology for workpiece detection and automatic feeding, which is applied in the direction of manufacturing tools, metal processing equipment, non-electric welding equipment, etc., can solve the problems of difficult processing detection, unqualified welding, high price, etc., so as to improve work efficiency, ensure product quality, Avoid the effect of welding failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

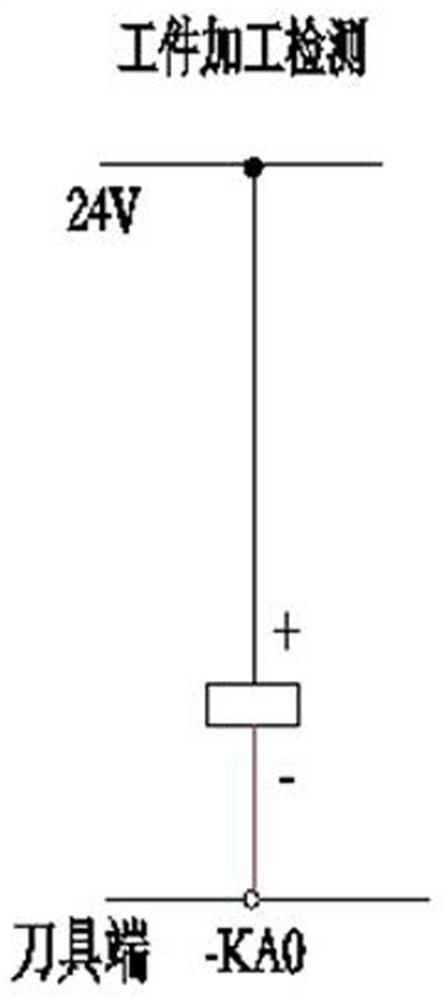

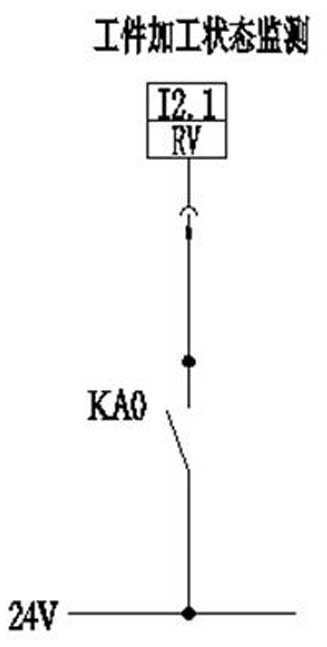

[0016] Such as figure 1 with figure 2 As shown, an automatic charge machine tool workpiece detection method, the steps are as follows: 1) Detection structure construction: including relays, wires, power supplies, and system input signal monitoring points;

[0017] 2) Relay reset, monitoring signals from zero;

[0018] 3) The detection structure is placed on the side of the tool, a wire is in contact with the tool, the relay wire is electrically, the monitoring signal is changed from 0 to 1, and the process continues;

[0019] 4) The monitoring signal has been 0, then the process is wrong, stops working, and detects whether there is no workpiece or workpiece.

[0020] The wires of the relays in the relay in step 1) are connected to the tool contact, and the relay is positive to turn on the power.

[0021] In step 3), the NC and the PLC interaction signal is DB125.1 in the detection structure, the corresponding NC address is $ A_IN [18]; when the tool is in contact with the workpie...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap