Multi-head linear motion mechanism for laser drilling

A linear motion, laser drilling technology, applied in laser welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of low module accuracy, reduced service life, equipment temperature effects, etc., to achieve simple structure, Ease of maintenance and reduction in quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with specific embodiment and accompanying drawing, the present invention is further elaborated and illustrated:

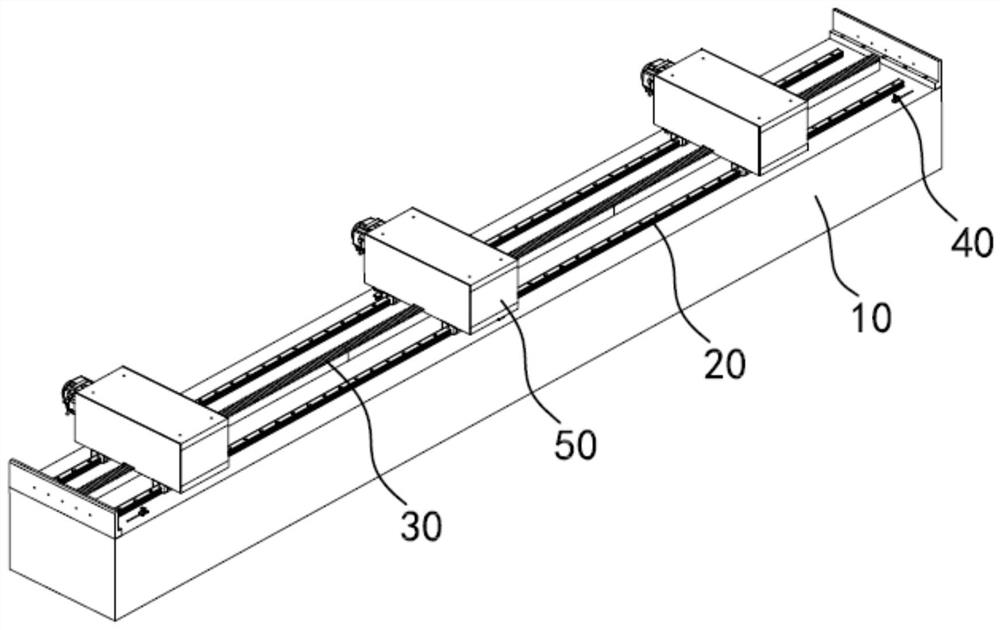

[0027] Please refer to figure 1 , a multi-head linear motion mechanism for laser drilling includes a base 10, a guide rail 20 located on the base 10, a rack 30, a plurality of first photoelectric induction switches 40, a plurality of mobile workbenches 50 and an electrical control device. The electrical control device is electrically connected to the first photoelectric sensor switch 40 and the mobile workbench 50 .

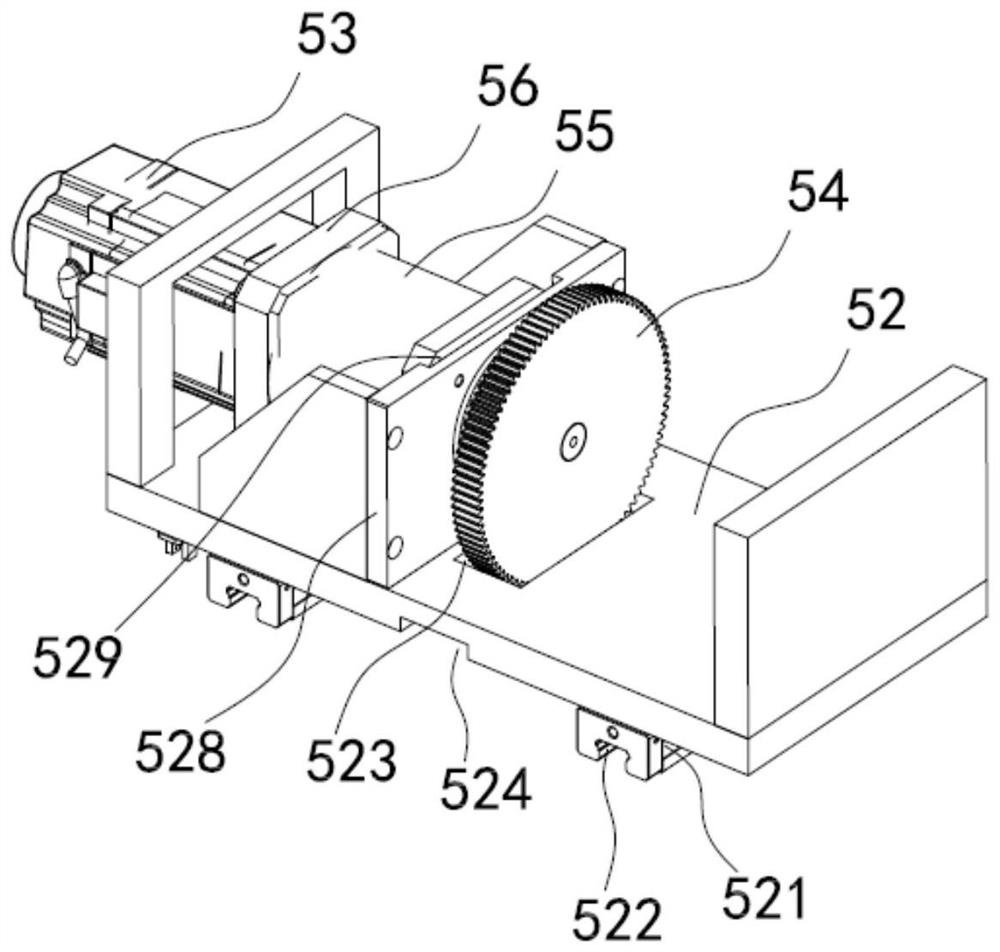

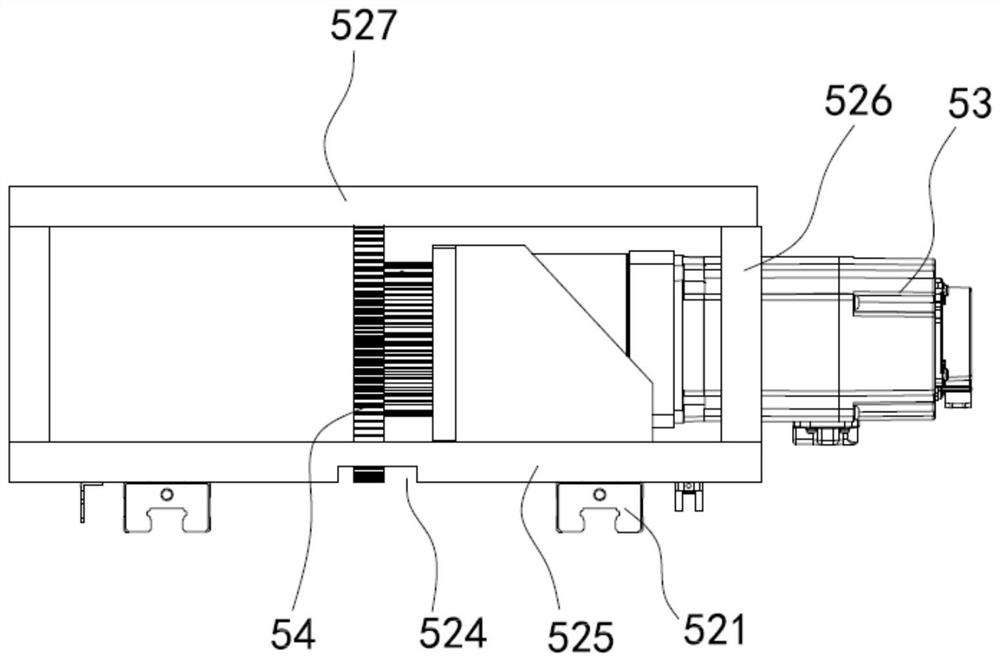

[0028] Please refer to figure 1 and Figure 4 , the rack 30 is fixed on the base 10 and is parallel to the guide rail 20 , a number of gear teeth are formed on the top surface of the rack 30 , and the bottom surface of the rack 30 is supported by the base 10 . Specifically, two guide rails 20 are arranged in parallel, and the rack 30 is located on the bisecting line between the two guide rails 20 . When the mobile workb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com