Light trailer air suspension system

An air suspension, lightweight technology, used in suspension, elastic suspension, vehicle components and other directions, can solve the problems of large unsprung mass, poor comfort, complex structure, etc., to extend tire life, improve braking performance, axle The effect of uniform charge distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

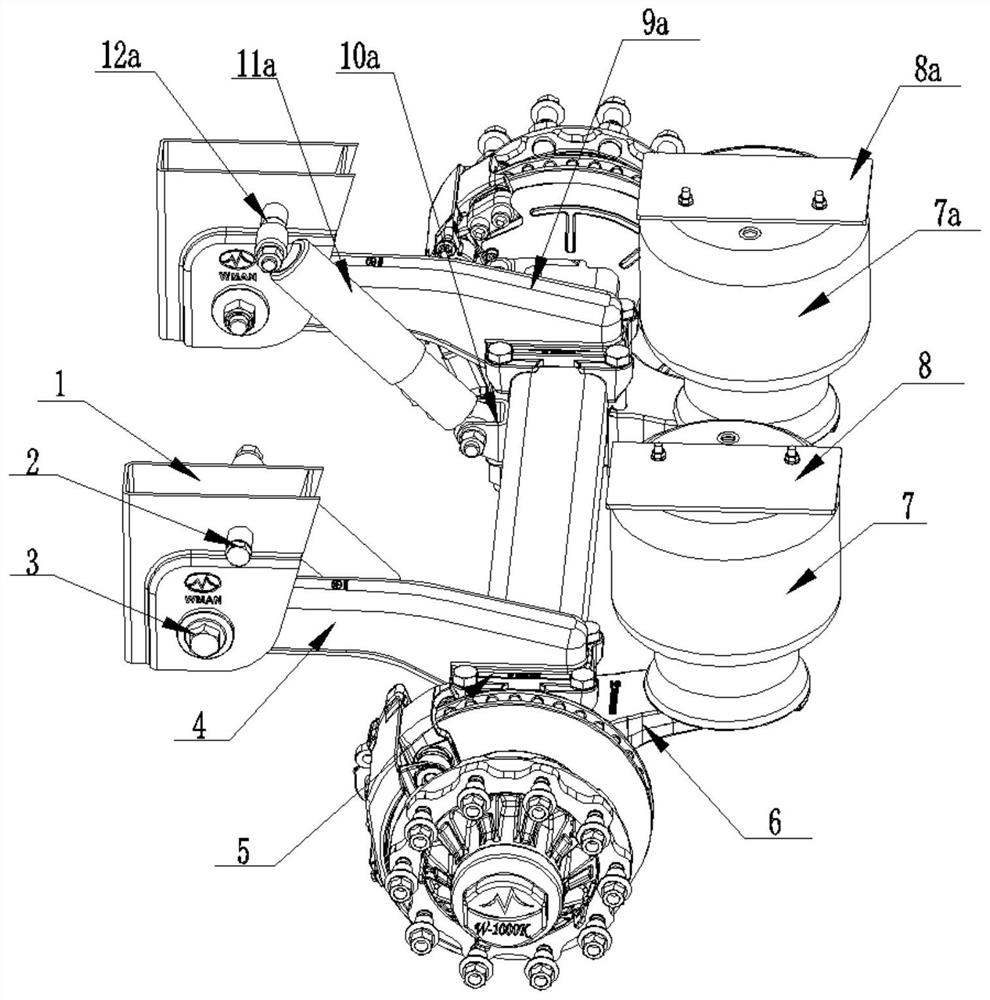

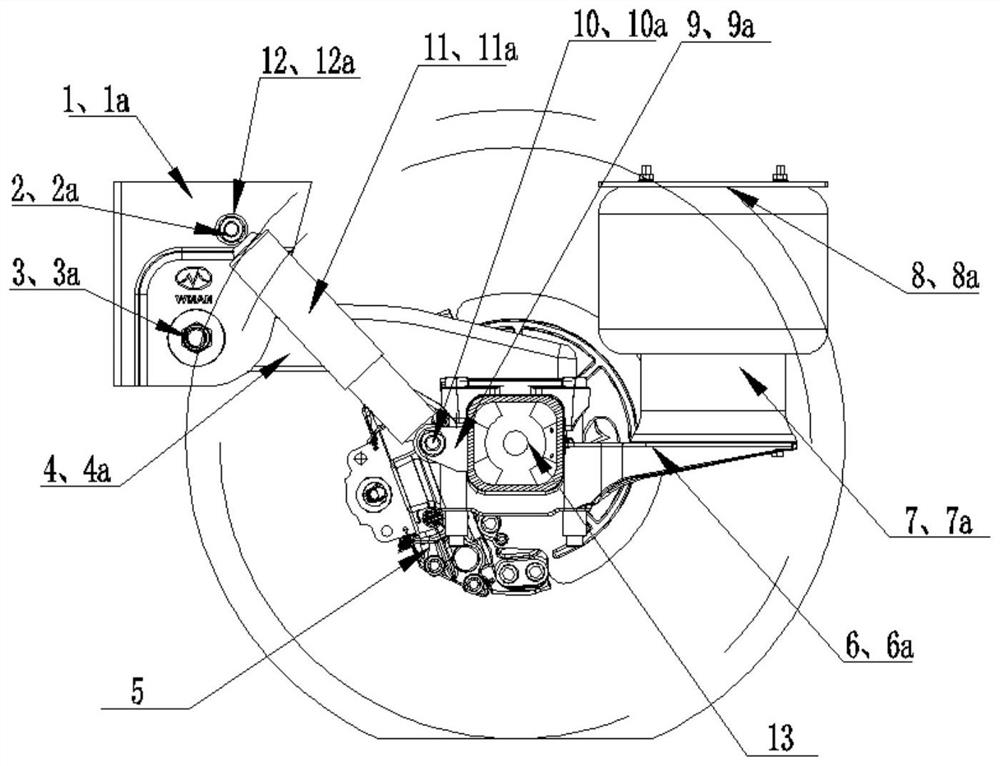

[0029] refer to Figure 1-2 , an air suspension system for a light-duty trailer, comprising left and right leaf spring bracket assemblies 1, 1a, left and right upper shock absorber pins 2, 2a, left and right upper guide beam pins 3, 3a, left and right upper guides Beam assembly 4, 4a, left and right saddle bolts 5, 5a, left and right airbag lower brackets 6, 6a, left and right bearing airbag assembly 7, 7a, left and right airbag cover plate 8, 8a, left, Right shock absorber bracket assembly 9, 9a, left and right lower shock absorber pin shaft 10, 10a, left and right shock absorber assembly 11, 11a and left and right bushing 12, 12a;

[0030] In the present invention, the rear ends of the left and right shock absorbers 11, 11a are hinged to the left and right shock absorber bracket assemblies 9, 9a through the left and right lower shock absorber pins 10, 10a, and the left and right shock absorbers The front ends of 11 and 11a are respectively hinged to the left and right leaf ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com