Device for preparing tetravalent uranium through electrolytic method, and spent fuel post-treatment system

A tetravalent uranium and electrolysis technology, applied in the electrolysis process, electrolysis components, reactor fuel elements, etc., can solve the problems of increasing the processing load of the uranium purification process, poor separation effect of uranium and plutonium, and unreasonable flow channel design. Increased yield, improved effectiveness, reduced dead volume effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

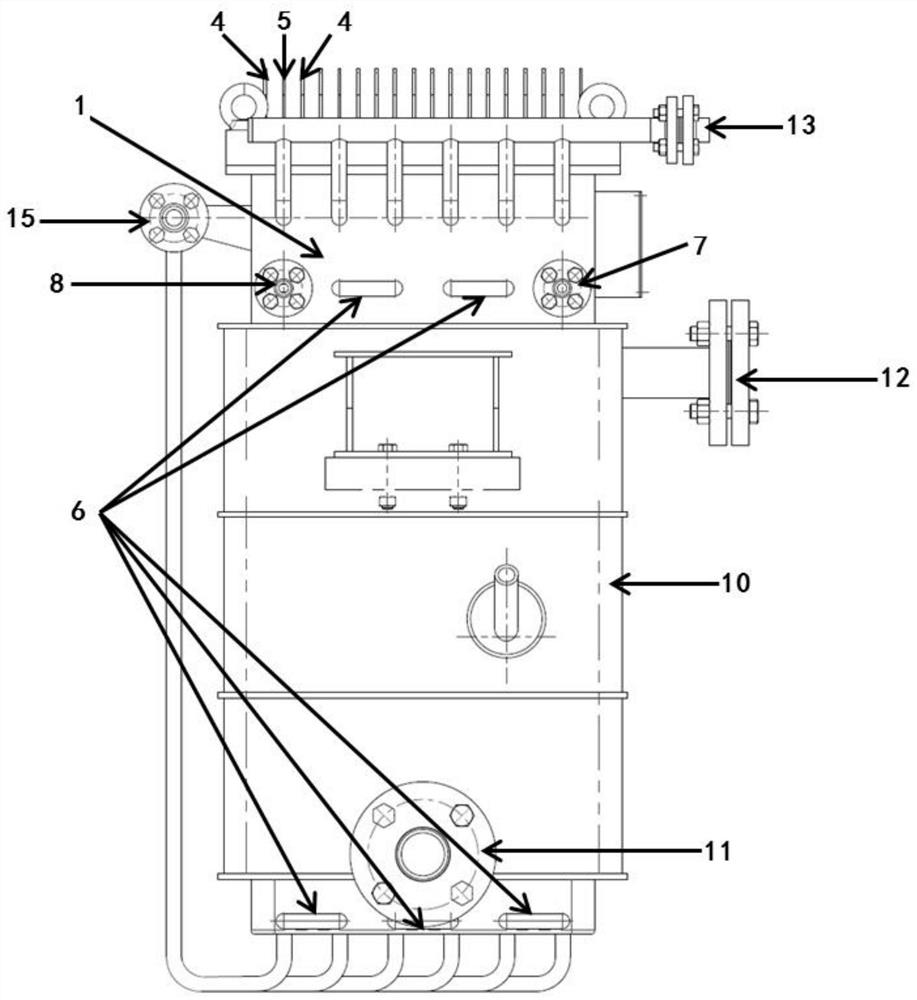

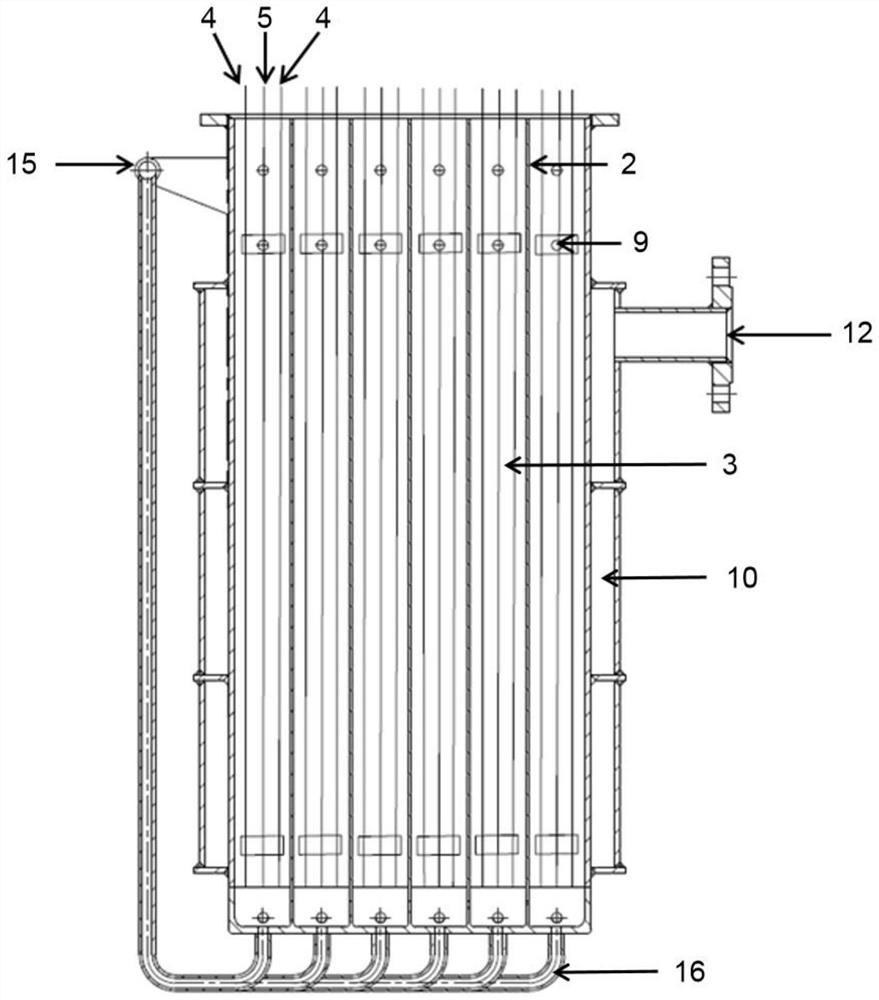

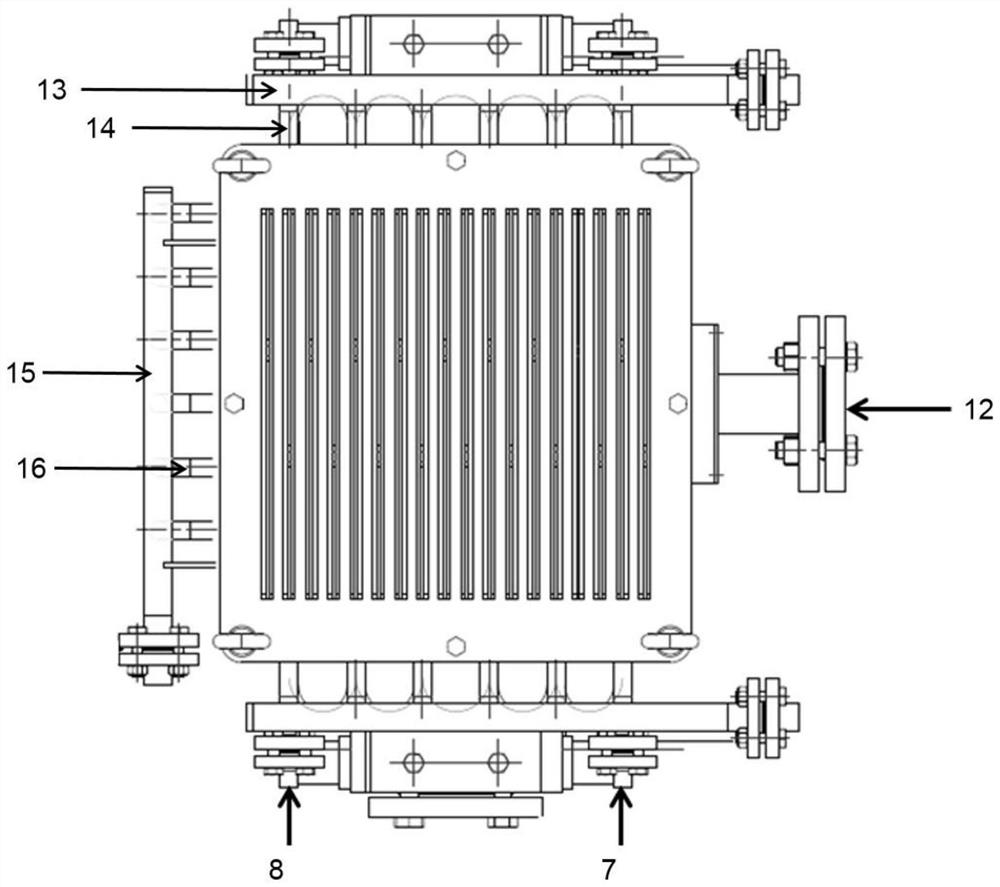

[0046] like figure 1 As shown, this embodiment discloses a device for preparing tetravalent uranium by electrolysis, including an electrolytic cell, the electrolytic cell includes a cell body 1, a cathode plate 4 and an anode plate 5 are arranged in the cell body 1, and a cell body 1 is also provided with Multiple partitions2. A plurality of separators 2 are arranged in parallel, and are arranged in the tank body 1 in sequence, and the tank body 1 is divided into a plurality of compartments 3. The tank body 1 is built with an electrolyte, and the electrolyte solution is filled in each compartment 3, and each Each compartment 3 is provided with a cathode plate 4 and an anode plate 5 . A plurality of compartments 3 are communicated in sequence, and each compartment 3 communicates with the upper / lower part of its adjacent upstream compartment, and communicates with the lower / upper part of its connected downstream compartment.

[0047] Specifically, the shape and size of the par...

Embodiment 2

[0065] This embodiment discloses a spent fuel reprocessing system, which includes a storage device and the device for preparing tetravalent uranium by electrolysis described in Embodiment 1. Among them, the storage device is used to store the uranium-plutonium feed liquid containing hexavalent uranium. In actual operation, the storage device may refer to the device for storing the feed liquid containing hexavalent uranium in the tetravalent uranium preparation system in the spent fuel reprocessing process. For example, the feed tank; the feed port 7 of the device for preparing tetravalent uranium by electrolysis is connected with the output end of the storage device, so that the feed solution containing hexavalent uranium is passed through as the electrolyte.

[0066] Further, the system of this embodiment also includes a uranium-plutonium separation device:

[0067] The uranium-plutonium separation device is connected to the outlet 8 of the device for preparing tetravalent ur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap