Aerogel-filled three-dimensional spacer fabric and preparation method thereof

A technology of spacer fabric and airgel fiber, which is applied in the direction of fabrics, textiles, textiles and papermaking, etc., can solve the problems of single function of three-dimensional spacer fabric, lack of temperature adjustment function and self-resetting function, etc., to improve self-resetting performance, Increase antistatic performance and good binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

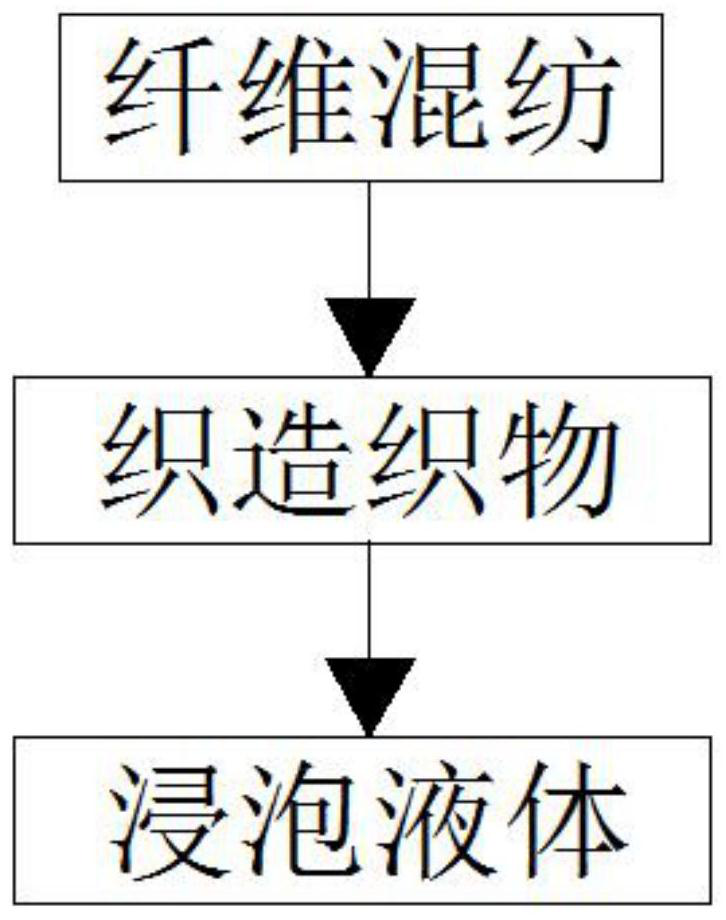

[0026] Further, a method for preparing an airgel-filled three-dimensional spacer fabric, using an airgel-filled three-dimensional spacer fabric, the steps of the preparation method of an airgel-filled three-dimensional spacer fabric are as follows:

[0027] Step 1: Flame-retardant fibers, airgel fibers, phase change fibers and shape memory fibers are blended using a blending machine;

[0028] Step 2: Then, the weft yarns are inserted through the weft insertion machine, and the warp and weft yarns are interwoven to form a veil layer. When the shed is opened, the spacer is placed, and the spacer yarns are interwoven. Complete a complete cycle of weaving to obtain a three-dimensional woven spacer fabric;

[0029] Step 3: After obtaining the three-dimensional woven spacer fabric, put the three-dimensional woven spacer fabric into the antistatic liquid for soaking.

[0030] Further, the flame-retardant fiber in the first step can be one of polyimide fiber, basalt fiber, polyphenyl...

Embodiment 1

[0033] The three-dimensional spacer fabric material includes the following raw materials and their weight fractions: 20 parts of flame-retardant fiber, 10 parts of airgel fiber, 10 parts of phase change fiber, 10 parts of shape memory fiber, and 3 parts of antistatic liquid.

[0034] The preparation steps are as follows:

[0035] a. taking the above-mentioned raw materials according to parts by weight;

[0036] Step 1: Flame-retardant fibers, airgel fibers, phase change fibers and shape memory fibers are blended using a blending machine;

[0037] Step 2: Then, the weft yarns are inserted through the weft insertion machine, and the warp and weft yarns are interwoven to form a veil layer. When the shed is opened, the spacer is placed, and the spacer yarns are interwoven. Complete a complete cycle of weaving to obtain a three-dimensional woven spacer fabric;

[0038] Step 3: After obtaining the three-dimensional woven spacer fabric, put the three-dimensional woven spacer fabric...

Embodiment 2

[0040] The three-dimensional spacer fabric material includes the following raw materials and their weight fractions: 25 parts of flame-retardant fibers, 16 parts of airgel fibers, 14 parts of phase-change fibers, 16 parts of shape memory fibers, and 4 parts of antistatic liquid.

[0041] The preparation steps are as follows:

[0042] a. taking the above-mentioned raw materials according to parts by weight;

[0043] Step 1: Flame-retardant fibers, airgel fibers, phase change fibers and shape memory fibers are blended using a blending machine;

[0044] Step 2: Then, the weft yarns are inserted through the weft insertion machine, and the warp and weft yarns are interwoven to form a veil layer. When the shed is opened, the spacer is placed, and the spacer yarns are interwoven. Complete a complete cycle of weaving to obtain a three-dimensional woven spacer fabric;

[0045] Step 3: After obtaining the three-dimensional woven spacer fabric, put the three-dimensional woven spacer fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com